High Volume Parts Production has revolutionized manufacturing across industries like automotive, machine building, and automation, enabling precision and scalability in parts production. At the heart of this transformation lies CNC machining, a method that guarantees unparalleled accuracy, consistency, and efficiency.

For over 12 years, CNCRUSH, a leading China CNC factory, has been delivering high-quality CNC machining services for global clients. Our expertise in crafting CNC Milled parts and CNC Turned parts ensures optimal solutions tailored to meet high-volume production demands. This article explores the critical role CNC machining plays in this arena and how partnering with a trusted provider like CNCRUSH can elevate your production capabilities.

Contents

- Understanding the Need for High Volume Parts Production

- What Makes CNC Machining Ideal for High-Volume Production?

- Types of CNC Machines Used in High Volume Parts Production

- Precision and Consistency in High Volume CNC Machining

- Challenges in High Volume CNC Machining and How to Overcome Them

- Key Considerations When Scaling Up CNC Machining

- Cost Analysis: High Volume CNC Machining vs. Traditional Methods

- Industry Applications of High Volume CNC Machining

- How CNCRUSH Supports High Volume CNC Machining Needs

- FAQs About High Volume Parts Production

Understanding the Need for High Volume Parts Production

Modern industries demand efficiency, precision, and scalability. High volume production caters to sectors like automotive, electronics, and medical devices, where consistency across large quantities is non-negotiable. CNC machining meets these demands through automated precision, reduced errors, and faster turnaround times.

Key Benefits of High Volume CNC Production:

- Enhanced repeatability.

- Reduced production costs through economies of scale.

- High-quality output that meets industry standards.

What Makes CNC Machining Ideal for High-Volume Production?

CNC machining is synonymous with precision and efficiency, thanks to its advanced computer-controlled operations. Its key advantages include:

- Automation: Eliminates human errors, ensuring consistency.

- Versatility: Handles diverse materials like aluminum, steel, and plastics.

- Speed: Rapid production cycles minimize lead times.

Pro Insight:

At CNCRUSH, we leverage cutting-edge CNC technology to deliver consistent CNC Milled parts and CNC Turned parts for high-volume orders, ensuring precision even at scale.

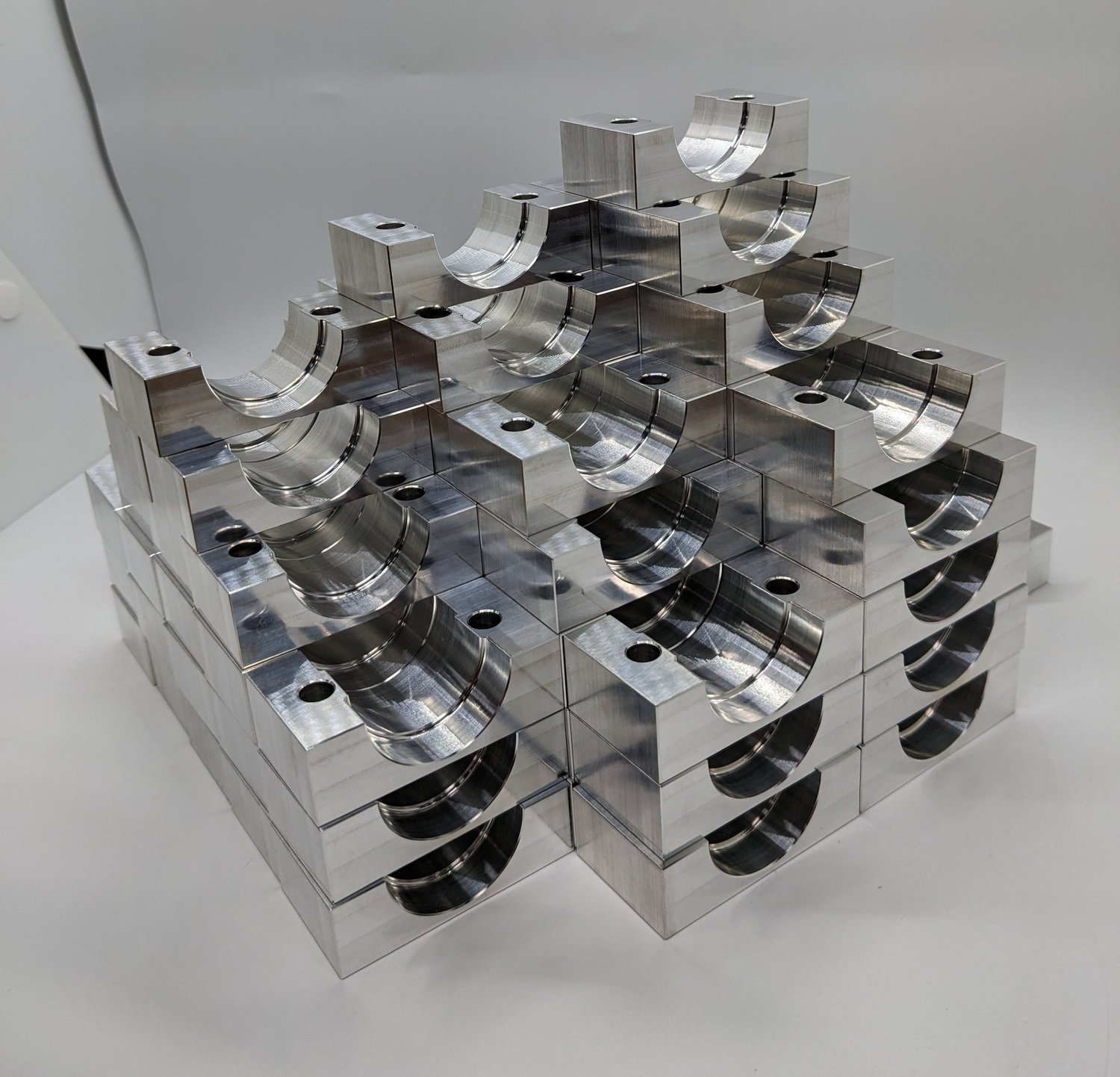

Types of CNC Machines Used in High Volume Parts Production

High-volume CNC machining often employs:

- CNC Mills: Perfect for precision machining of metal and plastic parts.

- CNC Lathes: Ideal for producing cylindrical components in bulk.

- Multi-Axis Machines: Efficiently manage complex geometries for diverse applications.

Table: Matching CNC Machines to Production Needs

| CNC Machine Type | Production Strength | Industries |

|---|---|---|

| CNC Milling Machine | Intricate part designs | Electronics, Automotive |

| CNC Turning Machine | High-speed cylindrical parts | Aerospace, Medical |

| Multi-Axis Machine | Complex, multi-angle parts | Automation, Robotics |

Precision and Consistency in High Volume CNC Machining

CNC machining ensures tight tolerances, often within ±0.01mm, critical for industries like aerospace and medical equipment. Unlike traditional manufacturing, CNC systems offer unmatched repeatability, ensuring every unit meets exact specifications.

Example:

Producing a batch of CNC Turned parts for automotive engines demands both dimensional accuracy and uniformity across thousands of units—a feat made possible by CNC technology.

Challenges in High Volume CNC Machining and How to Overcome Them

High-volume production isn’t without challenges, including:

- Tool Wear: Leads to inconsistent outputs over long runs.

- Machine Downtime: Reduces productivity.

- Material Waste: Inefficiencies in setup can cause excess scrap.

Solutions:

- Employ robust maintenance schedules.

- Use predictive analytics to preempt downtime.

- Optimize setup procedures to minimize waste.

At CNCRUSH, our extensive experience ensures these challenges are effectively managed, maximizing productivity and cost savings for our clients.

Key Considerations When Scaling Up CNC Machining

Scaling up from prototyping to full-scale production requires careful planning:

- Machine Capacity: Ensure adequate throughput to meet demand.

- Material Selection: Choose cost-effective, performance-oriented materials.

- Programming Expertise: Optimize CAM programming for speed and precision.

Pro Tip:

Partnering with a reliable provider like CNCRUSH can streamline this transition, as we specialize in high-volume CNC manufacturing services.

Cost Analysis: High Volume CNC Machining vs. Traditional Methods

While traditional methods like injection molding may appear cost-effective for certain applications, CNC machining provides greater flexibility and quality for high-complexity parts.

Table: Cost Comparison

| Aspect | CNC Machining | Traditional Methods |

|---|---|---|

| Initial Setup Cost | Moderate | High |

| Scalability | Excellent | Limited |

| Flexibility | High | Low |

| Material Waste | Low | Moderate |

Industry Applications of High Volume Parts Production CNC Machining

High-volume CNC machining plays a pivotal role across industries:

- Automotive: Engine components, transmission parts.

- Aerospace: Lightweight metal parts for aircraft.

- Electronics: Enclosures, connectors.

- Medical Devices: Precision surgical instruments.

At CNCRUSH, we serve these industries with tailored CNC machining services that deliver precision and reliability.

How CNCRUSH Supports High Volume CNC Machining Needs

With 12 years of expertise, CNCRUSH has established itself as a leader in high-volume CNC production. Our services include:

- Custom CNC Solutions: Tailored to your unique project needs.

- Expertise Across Materials: From aluminum to plastics, we provide versatile machining solutions.

- State-of-the-Art Facilities: Advanced equipment ensures consistent quality and rapid delivery.

Call to Action:

Partner with CNCRUSH to transform your high-volume manufacturing projects with our premium CNC machining services.

FAQs About High Volume Parts Production

Q1: What industries benefit most from high-volume CNC machining?

A: Automotive, aerospace, medical devices, and electronics are the top industries relying on CNC precision.

Q2: How does CNC machining compare to 3D printing for High Volume Parts Production?

A: CNC machining offers superior speed, material versatility, and surface finish compared to 3D printing.

Q3: Can CNCRUSH handle urgent High Volume Parts Production orders?

A: Yes, our efficient workflows ensure rapid turnaround times for urgent projects.

Q4: What materials can CNCRUSH process?

A: We specialize in aluminum, steel, plastics, and other common industrial materials.

Q5: How do I get started with CNCRUSH for High Volume Parts Production?

A: Visit our website and contact us for a custom consultation tailored to your project needs.

CNC machining has redefined High Volume Parts Production, combining precision, speed, and cost-effectiveness. With CNCRUSH as your partner, you gain access to industry-leading expertise, cutting-edge technology, and a commitment to excellence. Explore our CNC machining services today and unlock new possibilities for your manufacturing projects.