In today’s rapidly evolving manufacturing landscape, Precision Metalworking plays a critical role in producing high-quality, durable, and reliable components. Industries like automotive, machine building, and automation rely heavily on advanced technologies to meet their demanding requirements. CNC machining, with its unparalleled accuracy, efficiency, and versatility, has become the backbone of precision metal fabrication.

For over 12 years, CNCRUSH, a trusted China CNC factory, has specialized in delivering high-quality CNC machining services, focusing on CNC Milled parts and CNC Turned parts for global clients. This article explores 10 transformative ways CNC machining supports precision metalworking, highlighting its profound impact on manufacturing while guiding you toward the right solutions for your needs.

1. The Critical Role of CNC Machining in Precision Metalworking

The essence of precision metalworking lies in its ability to craft intricate parts with exceptional accuracy. CNC machining revolutionizes this process by integrating computer-controlled systems to handle complex designs with ease.

Key Benefits for Precision Metalworking:

- Accuracy: CNC machines achieve tolerances as tight as ±0.001 inches, ensuring flawless components.

- Repeatability: High-volume production benefits from consistent quality across thousands of parts.

- Material Versatility: Supports metals like aluminum, steel, brass, and more.

CNCRUSH Expertise:

We specialize in CNC machining services for industries that demand precision, including automotive and machine building. Our advanced capabilities ensure that every part meets stringent specifications.

2. Material Versatility: Meeting the Needs of Diverse Industries

CNC machining supports a wide array of metals, allowing manufacturers to choose the ideal material for their specific applications. From lightweight aluminum to robust steel, CNC machining handles them all with precision.

Material Applications in Precision Metalworking:

- Aluminum: Ideal for lightweight yet strong parts in aerospace and automotive industries.

- Steel: Essential for components requiring high strength and durability.

- Brass: Preferred for electrical and decorative applications due to its conductivity and aesthetic appeal.

Table 1: Common Metals Used in CNC Machining

| Material | Characteristics | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Automotive, Aerospace |

| Steel | Durable, versatile | Machine Building, Automation |

| Brass | Conductive, malleable | Electrical, Decorative |

At CNCRUSH, we combine material expertise with advanced CNC milling and turning to deliver custom solutions for diverse industries.

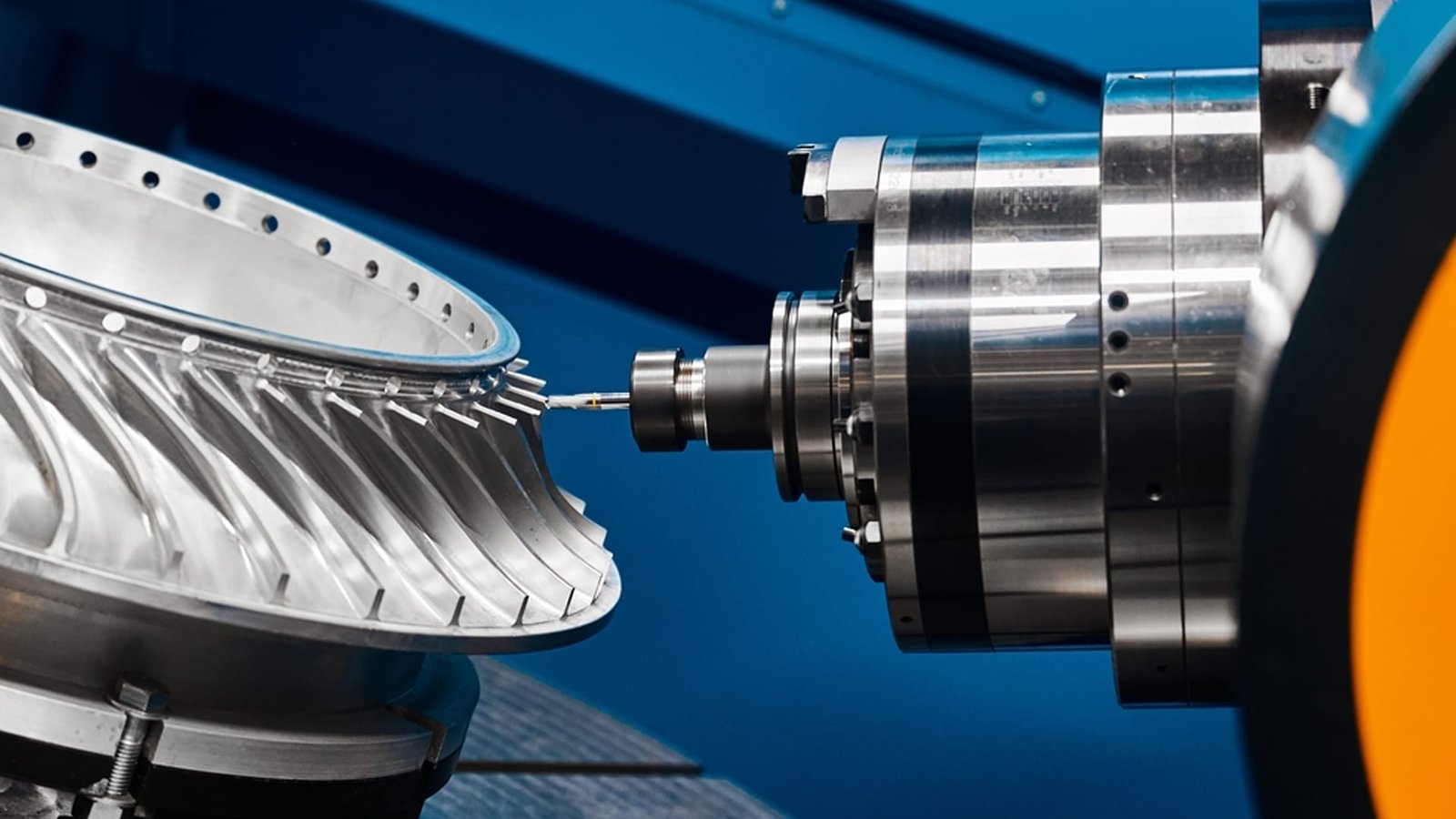

3. High-Precision CNC Milled Parts for Complex Designs

CNC milling is a cornerstone of precision metalworking, enabling the creation of intricate geometries with unmatched accuracy. Multi-axis CNC milling machines can perform simultaneous operations, reducing cycle times and improving efficiency.

Advantages of CNC Milled Parts:

- Complex Geometries: Ideal for intricate designs with tight tolerances.

- Surface Finishing: Smooth finishes for components requiring aerodynamic or aesthetic properties.

CNCRUSH’s Capabilities:

Our CNC Milled parts are tailored to meet the needs of industries like automotive and automation, delivering precision and durability.

4. CNC Turned Parts: Revolutionizing Cylindrical Component Production

CNC turning specializes in manufacturing cylindrical parts, such as shafts, bushings, and connectors, with exceptional speed and accuracy. This process is indispensable for machine building and automotive applications.

Key Features of CNC Turned Parts:

- Efficiency: High-speed turning processes ensure quick production cycles.

- Customization: Supports threading, grooving, and knurling for specialized components.

Example:

CNCRUSH produces CNC Turned parts for automation systems, where precision and reliability are critical for seamless operation.

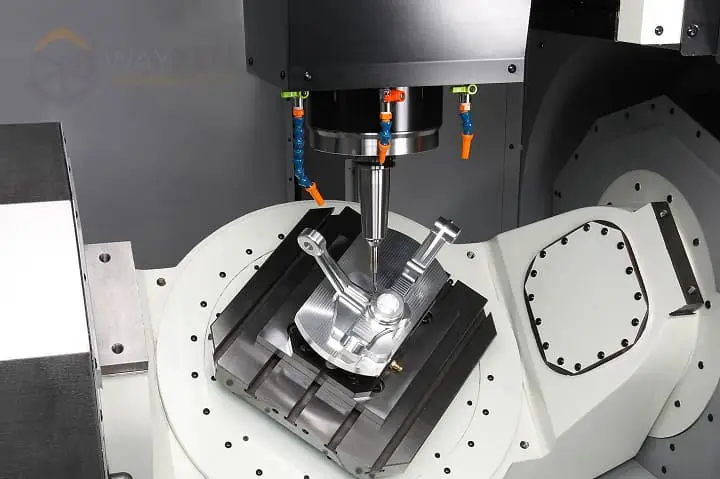

5. Enhancing Efficiency with Advanced CNC Machining Services

Efficiency is crucial in modern manufacturing, and CNC machining delivers through automation, reduced waste, and optimized workflows.

Efficiency Benefits:

- Automation: Reduces labor dependency and minimizes errors.

- Multi-Operation Machines: Completes milling, turning, and drilling in one setup.

Impact on Metalworking:

Manufacturers benefit from faster production cycles and lower costs, allowing them to scale operations while maintaining quality.

6. Surface Finishing for Precision Metalworking

In precision metalworking, surface finishing determines the performance and durability of components. CNC machining supports a variety of post-processing options, from polishing to anodizing.

Common Finishes in CNC Machining:

- Polishing: For smooth, aesthetic surfaces.

- Anodizing: Adds a protective layer to aluminum parts.

- Powder Coating: Durable finishes for corrosion resistance.

Table 2: Popular CNC Surface Finishes

| Finish Type | Benefits | Typical Applications |

|---|---|---|

| Polishing | Aesthetic, smoothness | Decorative parts, consumer goods |

| Anodizing | Corrosion resistance | Aerospace, Automotive |

| Powder Coating | Strength, durability | Machine Building, Outdoor Equipment |

CNCRUSH offers comprehensive finishing services to ensure your CNC Milled parts and CNC Turned parts meet functional and aesthetic requirements.

7. Custom CNC Solutions for Industry-Specific Needs

CNC machining’s adaptability allows manufacturers to develop tailored solutions for niche applications. From prototypes to production, custom CNC machining services meet unique challenges.

Applications of Custom CNC Solutions:

- Prototyping: Quick iterations to refine designs.

- Low-Volume Production: Cost-effective manufacturing for specialized components.

Why CNCRUSH?

Our custom CNC solutions cater to a wide range of industries, combining flexibility with precision.

8. Supporting Industry 4.0 in Precision Metalworking

Industry 4.0 integrates digital technologies with manufacturing, and CNC machining is at the forefront of this transformation. Real-time monitoring, IoT-enabled machines, and predictive maintenance enhance productivity.

CNC in the Digital Era:

- Data-Driven Decisions: Sensors collect data to optimize processes.

- Predictive Maintenance: Reduces downtime by addressing issues proactively.

At CNCRUSH, we embrace Industry 4.0, integrating smart technologies into our CNC machining services for improved efficiency.

9. Cost-Effectiveness: Balancing Quality with Affordability

While precision metalworking prioritizes quality, cost control is equally important. CNC machining reduces expenses through automation, reduced waste, and efficient material use.

Cost-Saving Features:

- Material Optimization: Maximizes yield from raw materials.

- Labor Reduction: One operator can oversee multiple machines.

CNCRUSH’s competitive pricing makes us the go-to provider for affordable CNC machining without compromising on quality.

10. Partnering with CNCRUSH for Precision Metalworking Excellence

Choosing the right CNC machining partner is critical to achieving success in precision metalworking. With 12 years of experience, CNCRUSH has built a reputation for excellence in producing CNC Milled parts, CNC Turned parts, and custom solutions for global clients.

Why Choose CNCRUSH:

- Expertise: Decades of experience in precision machining.

- Global Reach: Serving clients across industries worldwide.

- Comprehensive Solutions: From prototyping to high-volume production.

FAQ: Precision Metalworking with CNC Machining

1. What makes CNC machining ideal for precision metalworking?

CNC machining offers unparalleled accuracy, repeatability, and efficiency, meeting the demanding requirements of modern industries.

2. What industries benefit from CNC machining services?

Industries like automotive, machine building, automation, and aerospace rely on CNC machining for high-quality components.

3. Why choose CNCRUSH for CNC machining?

With 12+ years of expertise, CNCRUSH delivers CNC Milled parts, CNC Turned parts, and custom solutions tailored to your needs.

4. What materials does CNCRUSH specialize in?

We work with metals like aluminum, steel, brass, and plastics, ensuring versatility for diverse applications.

At CNCRUSH, we are committed to excellence in precision metalworking. Whether you need high-quality CNC machining services, intricate CNC Milled parts, or reliable CNC Turned parts, our team delivers unmatched results. Contact us today to discuss your project and learn how we can support your manufacturing goals!