CNC Milling and Drilling of connecting rods is one of the most critical processes in the automotive and machine building industries. Precision here directly influences engine reliability, durability, and efficiency. At CNCRUSH, we understand these challenges deeply: with 12 years of CNC machining service experience, we have provided global clients with CNC Milled parts and CNC Turned parts for automotive, automation, and industrial applications. This article explores the techniques, challenges, and opportunities of CNC Milling and Drilling for connecting rods—while showing why choosing the right partner makes all the difference.

1. CNC Milling and Drilling – Why Connecting Rod Accuracy Matters

The accuracy of CNC Milling and Drilling in connecting rods defines how smoothly power transfers from the piston to the crankshaft. Even a minor deviation leads to imbalance, higher wear, and decreased engine life. Precision machining is not optional—it is the backbone of automotive engine performance.

2. CNC Machining Service and Its Role in Connecting Rod Manufacturing

A professional CNC machining service ensures consistent tolerances within microns. For connecting rods, that means bore alignment, surface finish, and dimensional stability across mass production. CNCRUSH’s services combine milling, drilling, and turning solutions tailored to meet strict ISO standards.

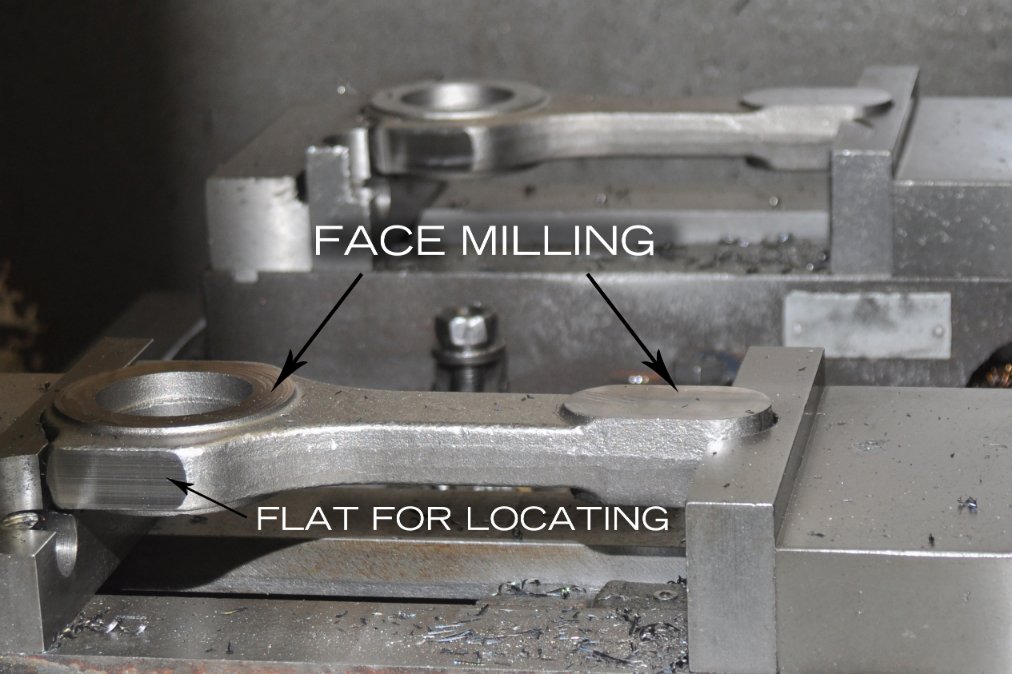

3. CNC Milled Parts for High-Strength Connecting Rods

High-strength connecting rods often require CNC Milled parts from forged aluminum, steel, or titanium. The milling process shapes the rod’s profile, ensuring weight balance and fatigue resistance. At CNCRUSH, our expertise in CNC Milled parts helps automotive clients achieve lightweight yet durable solutions.

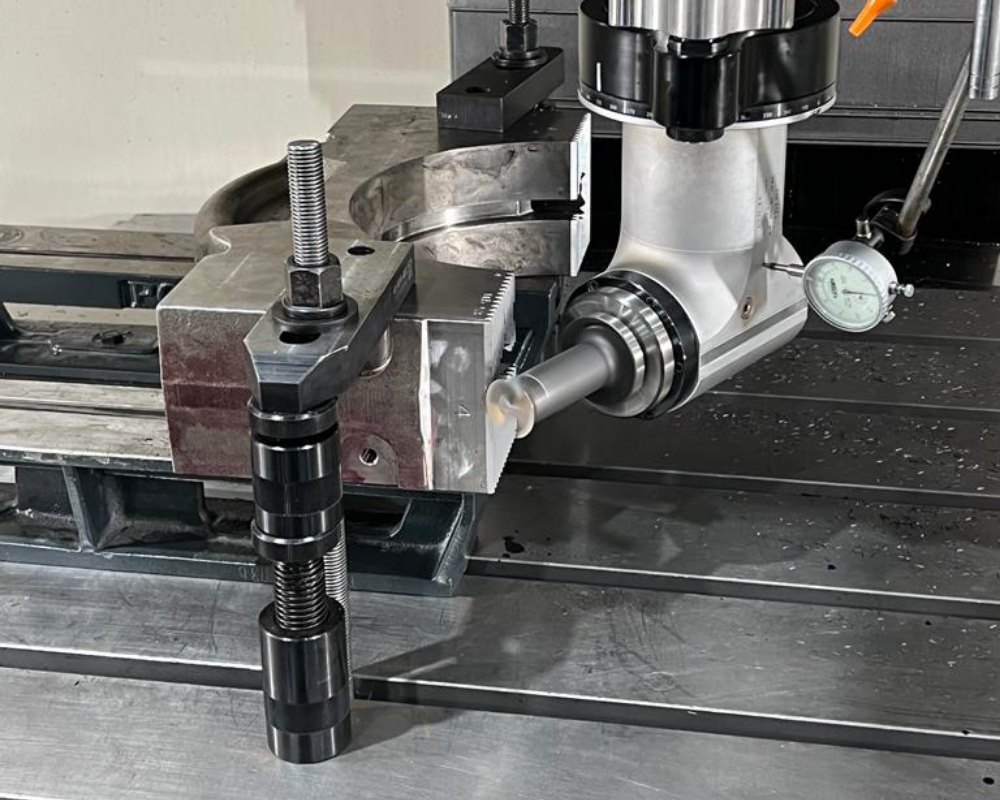

4. CNC Turned Parts for Precision Bearing Seats

Bearing seats in connecting rods demand exceptional roundness and smoothness. CNC Turned parts play a vital role here—turning guarantees concentricity and surface finish, enabling reliable lubrication and minimal friction under high load conditions.

5. CNC Milling and Drilling Techniques for Weight Reduction

Weight reduction without sacrificing strength is a positive achievement in connecting rod engineering. Advanced CNC Milling and Drilling introduces pocket milling, optimized hole patterns, and precision surface machining—reducing weight while enhancing rigidity.

6. CNC Machining Service Challenges in Automation and Automotive

A major negative sentiment in the industry arises from failures caused by poor machining: misaligned bores, uneven drilling, or burrs leading to premature failures. Only with a trusted CNC machining service can automotive and automation industries secure defect-free connecting rods.

7. CNC Milled Parts in Machine Building Applications

Beyond automotive, CNC Milled parts play a strong role in machine building. Connecting rods in compressors, industrial pumps, and robotic actuators rely on precise milling and drilling to achieve stable motion. Our factory at CNCRUSH ensures scalable and repeatable machining for such industrial demands.

8. CNC Turned Parts and Surface Treatments for Longevity

After CNC Turned parts are produced, surface treatments such as shot peening, anodizing, or nitriding are often applied. This improves fatigue strength and wear resistance. Without proper turning accuracy, however, surface treatments cannot compensate for dimensional flaws.

9. CNC Milling and Drilling Innovations – Multi-Axis Machining

Modern CNC Milling and Drilling uses multi-axis machining centers to complete multiple operations in a single setup. This reduces errors, saves time, and ensures tighter tolerances. At CNCRUSH, our use of advanced machining centers ensures global clients receive cutting-edge solutions.

10. CNC Machining Service as a Competitive Advantage

Choosing the right CNC machining service transforms a negative challenge into a positive competitive advantage. CNCRUSH, with 12 years of experience, offers not only CNC Milled parts and CNC Turned parts but also engineering support to optimize connecting rod designs for better manufacturability.

Comparative Table 1: Milling vs Drilling in Connecting Rods

| Aspect | CNC Milling | CNC Drilling |

|---|---|---|

| Purpose | Shaping, contouring, pocketing | Bore creation, oil channeling |

| Tolerance | ±0.01 mm | ±0.005 mm |

| Strength Contribution | Defines geometry, weight distribution | Ensures alignment, lubrication |

| Typical Applications | Side profiles, weight pockets | Pin bore, oil hole drilling |

Comparative Table 2: CNC Milled Parts vs CNC Turned Parts

| Feature | CNC Milled Parts | CNC Turned Parts |

| Typical Shape | Flat, complex 3D geometries | Cylindrical, concentric features |

| Relevance to Rods | External profiles, balance cuts | Bearing seats, journal interfaces |

| Surface Finish | Moderate to fine | Very fine, critical for lubrication |

| Applications | Automotive, machine building, robotics | Automotive, automation, compressors |

FAQ – CNC Milling and Drilling of Connecting Rods

Q1: Why is CNC Milling and Drilling important for connecting rods?

Because these processes ensure weight balance, durability, and engine efficiency by maintaining tight tolerances.

Q2: How do CNC Milled parts improve automotive performance?

They reduce unnecessary weight while maintaining strength, improving fuel efficiency and reliability.

Q3: What role do CNC Turned parts play in connecting rods?

They provide precise bearing seats, ensuring smooth rotation and reducing wear in engines.

Q4: Why choose CNCRUSH for CNC machining service?

With 12 years of experience, CNCRUSH specializes in CNC Milled parts and CNC Turned parts, serving global automotive and machine building industries with precision and reliability.

Q5: Can CNC Milling and Drilling help in automation industries?

Yes, these processes create reliable and consistent connecting rods for robotics, compressors, and automated systems.

Final Thoughts

The CNC Milling and Drilling of connecting rods is a decisive factor in engine and machinery performance. Precision cannot be compromised—errors lead to inefficiency and costly breakdowns. That is why choosing an expert partner like CNCRUSH is vital. With our CNC machining service, we help clients in automotive, machine building, and automation industries achieve excellence through CNC Milled parts and CNC Turned parts—backed by 12 years of proven expertise.