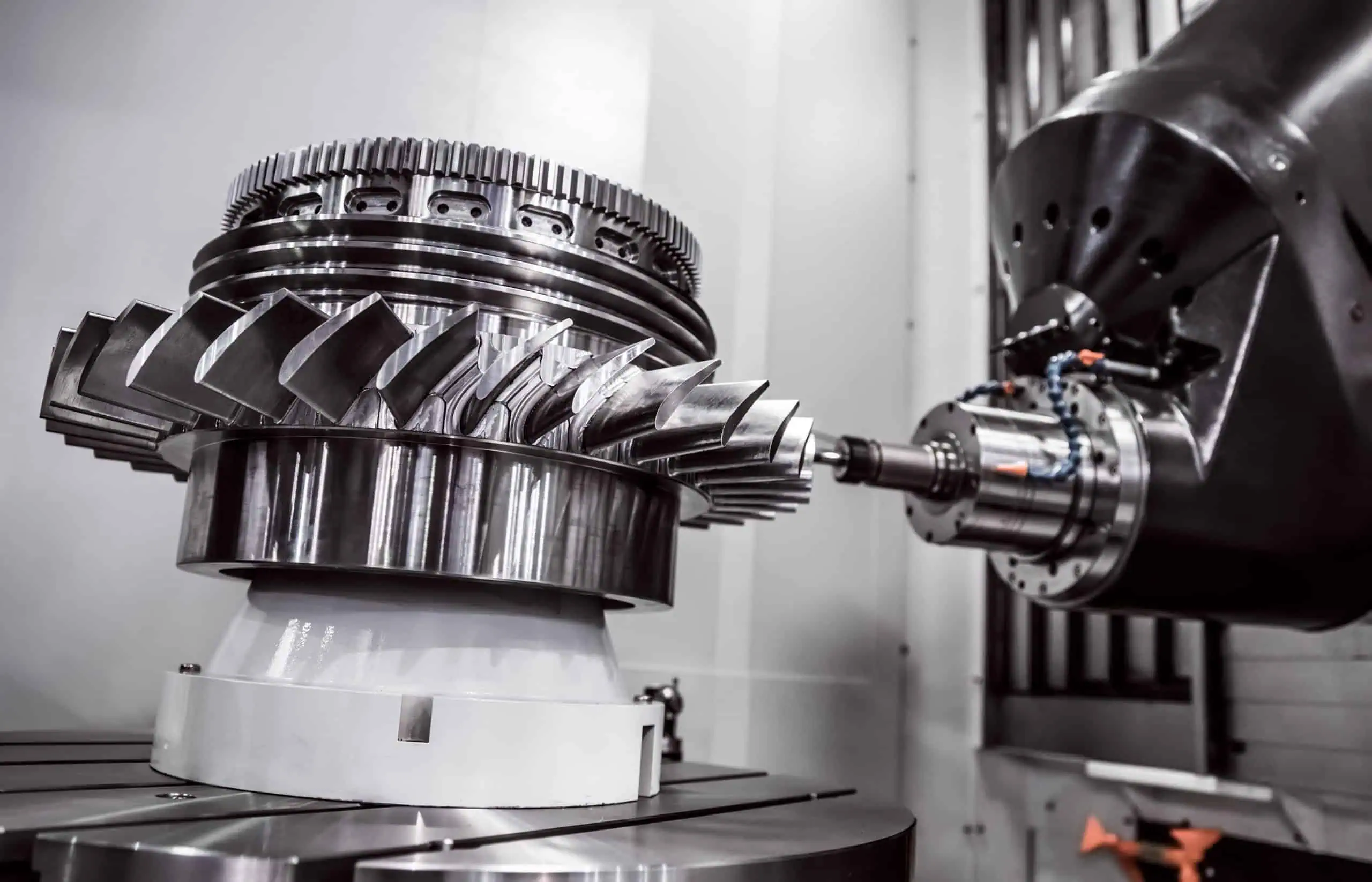

In the modern manufacturing world, CNC milling machines have been at the forefront of transforming industries, especially metalworking. These highly advanced machines have revolutionized how companies design and produce parts, improving precision, efficiency, and versatility. This article will explore the seven significant ways CNC milling machines have reshaped metalworking, and how manufacturers, including companies like CNCRUSH, are leveraging these advancements to offer cutting-edge CNC machining services to clients globally.

Introduction

CNC milling machines have brought about a seismic shift in the metalworking industry, allowing manufacturers to create complex, high-precision parts at a scale and speed previously unattainable. From the aerospace industry to automotive manufacturing, CNC machining has become indispensable. This technology empowers businesses to craft highly detailed, accurate, and consistent components for diverse applications.

At CNCRUSH, a leading CNC machining service provider based in China, we specialize in offering precision CNC milling and turning solutions. With over 12 years of experience, our team is committed to delivering CNC milled parts and CNC turned parts with exceptional quality. Whether you’re in need of components for automotive, machine building, or automation, CNCRUSH’s professional CNC machining services are designed to meet your most demanding needs.

In this article, we will provide an in-depth analysis of how CNC milling machines have revolutionized metalworking and why it’s essential for businesses to adapt to this transformative technology.

1. Precision and Consistency: How CNC Milling Machines Enhance Metalworking Accuracy

One of the most significant advantages CNC milling machines offer is unparalleled precision and consistency. Unlike traditional machining methods, CNC machines are guided by computer-generated instructions, ensuring that each part is manufactured to exact specifications.

With CNC milling, companies can produce parts with tight tolerances, ensuring that components meet the strictest quality standards. This is particularly critical in industries such as aerospace and automotive, where any deviation in part size or shape could lead to catastrophic failures.

At CNCRUSH, we understand the importance of precision in CNC milling and CNC turning services. Our factory is equipped with advanced CNC machinery capable of producing CNC milled parts and CNC turned parts to the highest standards of accuracy.

2. Increased Efficiency and Faster CNC Milling Times

CNC milling machines have drastically reduced production times. Traditional machining processes require more manual intervention, which can lead to errors and inefficiencies. CNC machines, on the other hand, automate the entire process, from loading raw material to producing the final part, ensuring faster turnaround times.

At CNCRUSH, we leverage our CNC machining services to produce large batches of CNC milled parts and CNC turned parts with quick lead times. Our advanced machinery and experienced team ensure that production is both fast and efficient, reducing downtime and maximizing productivity for our clients.

3. Flexibility and Versatility in CNC Milling

CNC milling machines are capable of handling a wide range of materials, including metals such as aluminum, steel, brass, and plastics. This versatility allows manufacturers to produce components for various industries, from automotive to machine building and automation.

Our CNC machining services at CNCRUSH are designed to cater to a wide range of materials and requirements. Whether it’s CNC milling or turning of aluminum, steel, or brass, we offer customized solutions to meet the unique needs of our clients.

4. Cost-Effective CNC Milling

By reducing labor costs and minimizing material waste, CNC milled machines help businesses lower production costs. Since CNC machines can operate continuously without the need for breaks or rest, production costs are further reduced, making it an excellent option for high-volume manufacturing.

For companies like CNCRUSH, offering affordable CNC machining services is a priority. With our state-of-the-art machinery, we can offer cost-effective solutions for manufacturing CNC milled parts and CNC turned parts, without compromising on quality.

5. Complexity Made Easy: The Capability to CNC Milling Intricate Designs

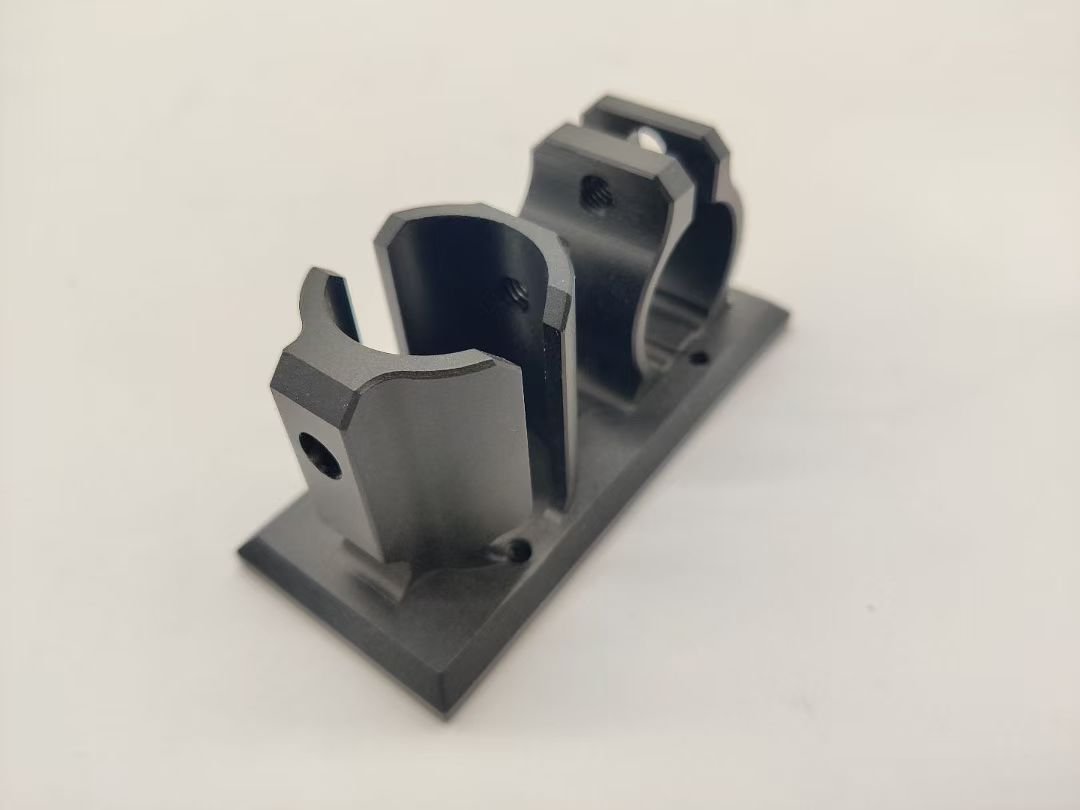

One of the greatest benefits of CNC milled machines is their ability to produce complex designs with intricate details that would be nearly impossible with manual methods. Whether it’s precise geometric patterns, complex 3D shapes, or fine details, CNC milled machines excel at transforming complex CAD designs into tangible parts.

At CNCRUSH, we specialize in producing intricate CNC milled parts and CNC turned parts for clients in industries such as automotive and machine building. Our experienced team of machinists ensures that even the most complicated designs are manufactured to perfection.

6. Reduced Human Error and Improved Safety in CNC Milling

Human error is a common risk in traditional machining methods, which can lead to defective parts, costly rework, and safety hazards. CNC milled machines mitigate these risks by automating the manufacturing process, reducing human intervention, and ensuring higher safety standards.

In our factory, CNCRUSH takes safety seriously. With the precision and automation offered by CNC machining services, we have significantly reduced the potential for human error and improved the safety of our operations, providing peace of mind to our clients.

7. Enhancing the Future of CNC Milling with Industry 4.0

As part of Industry 4.0, CNC milled machines are increasingly being integrated with IoT (Internet of Things) technologies, allowing real-time monitoring, predictive maintenance, and remote control of machinery. This trend is transforming the metalworking industry, enabling companies to optimize their operations and improve efficiency.

At CNCRUSH, we are always looking ahead. We are excited about the future of CNC machining and are continuously upgrading our processes with the latest technologies. Our clients can rely on our CNC machining services to not only meet today’s needs but also adapt to the future of manufacturing.

Tables:

Table 1: CNC Milling vs. Traditional Machining: Key Differences

| Feature | CNC Milling | Traditional Machining |

|---|---|---|

| Precision | High precision and consistency | Prone to human error |

| Production Time | Faster production | Slower, more manual intervention |

| Flexibility | Can handle various materials | Limited to certain materials |

| Cost Efficiency | Reduced labor and waste | Higher labor and material waste |

| Complexity | Can manufacture intricate designs | Difficult to produce complex parts |

Table 2: Key Industries Using CNC Milling Machines

| Industry | Applications |

|---|---|

| Aerospace | Aircraft components, engine parts, and landing gear |

| Automotive | Engine components, transmission parts |

| Machine Building | Custom machine parts, industrial machinery |

| Automation | Robotics components, control systems |

FAQs:

Q1: What materials can CNC milling machines handle?

A1: CNC milled machines are highly versatile and can work with a variety of materials, including metals like aluminum, steel, brass, and plastics. This flexibility makes them suitable for industries such as automotive, aerospace, and machine building.

Q2: How does CNC machining improve production efficiency?

A2: CNC machining automates the manufacturing process, reducing the need for manual intervention, which speeds up production and minimizes errors. This results in faster turnaround times and higher overall efficiency.

Q3: Can CNC milling machines handle complex designs?

A3: Yes, CNC milling machines are designed to handle intricate and complex designs with high precision. This capability is essential in industries like aerospace and automotive, where components require detailed specifications.

Q4: How does CNCRUSH ensure high-quality CNC milled services?

A4: At CNCRUSH, we use state-of-the-art CNC machinery and employ highly skilled professionals with over 12 years of experience. Our focus on precision and quality ensures that our CNC milled parts and CNC turned parts meet the highest standards.

Q5: Is CNC machining cost-effective for large production runs?

A5: Yes, CNC machining is cost-effective for large production runs as it minimizes labor costs and material waste. The automation and speed of CNC milling machines also make them ideal for high-volume manufacturing.

Conclusion:

CNC milling machines have undeniably revolutionized metalworking by offering unparalleled precision, efficiency, and versatility. At CNCRUSH, we are proud to be at the forefront of this technological transformation, providing high-quality CNC machining services to global clients. Whether you need CNC milled parts or CNC turned parts for automotive, machine building, or automation applications, we have the expertise and technology to deliver exceptional results. Embrace the power of CNC milling and let us help you take your manufacturing capabilities to the next level.