CNC milling machines have emerged as one of the most transformative technologies in modern manufacturing. From automotive to aerospace, machine building, and automation, CNC milling is helping industries meet their precise needs with efficiency and high-quality outputs. The ability of CNC machining services to produce intricate and high-tolerance CNC Milled Parts is revolutionizing the way manufacturers approach metalworking and machining. In this article, we’ll delve into how CNC Milling is reshaping the landscape of metalworking, the specific advantages it offers to industries, and why businesses are increasingly turning to CNC milling as a preferred manufacturing solution.

CNC Machining plays a pivotal role in industries like automotive and machine building, where precision, speed, and repeatability are non-negotiable. For over 12 years, CNCRUSH has been a trusted name in CNC machining services, specializing in CNC Milled Parts and CNC Turned Parts. With a reputation built on experience and dedication to high-quality solutions, CNCRUSH offers world-class services to clients globally.

What is CNC Milling and How Does It Work?

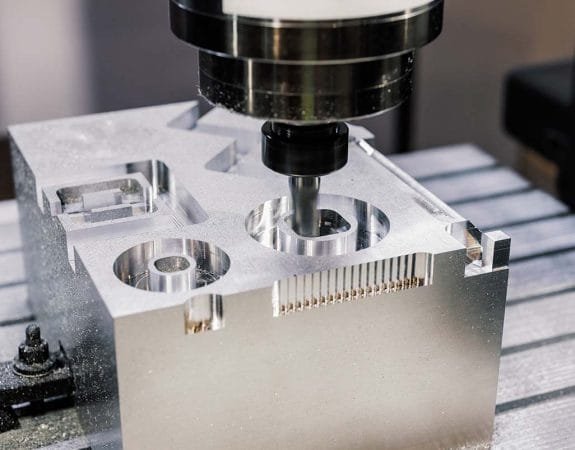

CNC milling, or Computer Numerical Control milling, refers to a manufacturing process that uses rotating cutting tools to remove material from a workpiece to achieve the desired shape. The workpiece is fixed in place while the tool moves along multiple axes, allowing for the creation of complex shapes with high precision.

Unlike traditional machining, where the operator manually guides the cutting tool, CNC milling relies on computer programming to control the entire process. This results in improved accuracy, faster turnaround times, and the ability to produce CNC Milled Parts that meet exact specifications.

CNC milling is essential for industries requiring detailed, complex parts that traditional methods simply cannot deliver. For example, in automotive and machine building industries, where every part must meet rigorous standards, CNC milling provides a highly reliable and efficient solution.

The Evolution of CNC Milling Machines in the Manufacturing Industry

The evolution of CNC milling machines has been driven by the need for precision, speed, and automation. Initially, manual milling machines were used for basic operations, but over time, computer programming allowed for more complex and precise operations. Today, CNC milling machines are highly sophisticated, featuring multi-axis capabilities that allow for the creation of intricate parts with extremely tight tolerances.

In recent years, advancements in CNC technology have led to the integration of additive manufacturing, automation, and even AI-driven optimizations. CNC Machining Services like those provided by CNCRUSH take full advantage of these developments, enabling businesses in industries such as automotive and machine building to streamline production and deliver high-quality CNC Milled Parts at competitive prices.

The Importance of CNC Milling in Automotive and Machine Building

The automotive and machine building industries demand high-quality parts that meet stringent standards of performance, reliability, and precision. CNC milling machines are perfect for producing components like engine parts, suspension brackets, transmission gears, and other critical elements that need to fit together seamlessly.

CNC Milled Parts are indispensable in these sectors because they offer unparalleled accuracy, enabling manufacturers to produce parts that fit precisely and perform reliably. In automotive manufacturing, for example, CNC milling machines create the precise geometries required for engine components and structural parts, ensuring safety and functionality.

With CNC Machining Services, companies like CNCRUSH offer expertise in the production of CNC Milled Parts and CNC Turned Parts that are designed to meet the specific needs of the automotive and machine building industries, ensuring high efficiency and reduced costs.

How CNC Milling Machines Improve Product Quality and Efficiency

One of the primary advantages of CNC milling over traditional methods is the significant improvement in product quality. CNC milling machines can produce parts with incredible accuracy and repeatability. Once a CNC program is created, the machine can make the same part thousands of times, all to the same specifications.

This level of precision is essential in industries like aerospace and automotive, where even the smallest deviations can lead to failures. CNC milling also reduces the need for post-production modifications, helping companies avoid costly reworks.

For example, CNC Milled Parts used in automotive components must withstand extreme conditions, including high stress and heat. CNC milling ensures that parts meet the strictest standards for durability, reducing the risk of defects and improving product performance.

Key Features of Modern CNC Milling Machines

Modern CNC milling machines come equipped with several advanced features that make them even more efficient, precise, and versatile. Some of the key features include:

- Multi-Axis Capabilities: Modern CNC milling machines can move in multiple directions, allowing for more complex shapes and reducing the need for multiple setups.

- Automatic Tool Changers (ATC): These machines can automatically switch between tools, allowing for greater flexibility and faster production cycles.

- High-Speed Spindles: Increased spindle speed improves the efficiency of material removal, reducing cycle times and increasing productivity.

- Advanced Computer Systems: State-of-the-art software and control systems provide precise control over the entire milling process, allowing for quick adjustments and real-time error detection.

These advancements enable manufacturers to produce CNC Milled Parts that are not only highly precise but also manufactured more efficiently, driving down costs and increasing overall productivity.

CNC Milling vs. Traditional Milling: Which is Better for Metalworking?

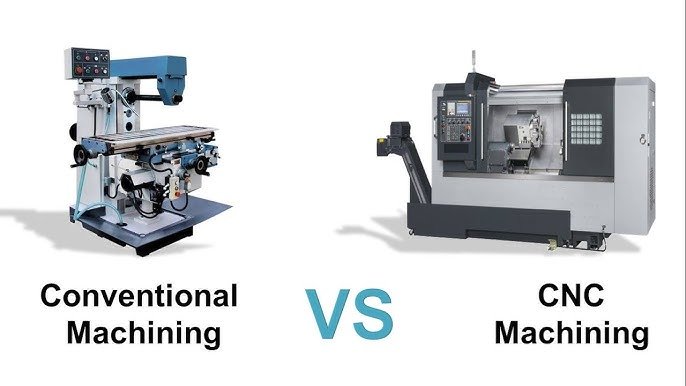

When comparing CNC milling to traditional milling, the primary advantage of CNC precision milling is its automation and precision. Traditional milling relies on human operators to control the machine, which can lead to inconsistencies and errors. CNC precision milling, however, uses computer programs to control every aspect of the process, leading to superior accuracy, faster production times, and fewer errors.

Additionally, CNC precision milling machines are more versatile, capable of handling a wide variety of materials, from aluminum to steel and plastics. This makes CNC milling ideal for industries like automotive, where different materials are used for various parts. CNC Milled Parts produced using these machines are consistent, high-quality, and cost-effective, making CNC precision milling the preferred choice for metalworking.

Emerging Trends in CNC Milling Technology

As technology continues to evolve, so does CNC milling. Some of the latest trends in CNC precision milling include:

- Integration with Additive Manufacturing: Some companies are integrating 3D printing with CNC precision milling, allowing for faster prototyping and more customized parts.

- Automation and Robotics: The automation of CNC milling processes is increasing, with robots handling tasks like part loading and unloading to improve production speeds.

- AI and Machine Learning: Artificial intelligence is being used to optimize CNC milling processes, improving efficiency and reducing errors.

These trends are making CNC Machining Services even more efficient and capable of producing high-quality CNC Milled Parts with faster turnaround times, making CNC precision milling an essential tool for businesses in industries like machine building and automotive manufacturing.

How CNC Machining Services are Enhancing Automation and Robotics

Automation and robotics have transformed the manufacturing industry, and CNC Machining Services are at the heart of this transformation. CNC precision milling machines are increasingly being integrated with robotic systems to streamline production processes. For instance, robots can handle material loading and unloading, while CNC machines focus on machining tasks.

This integration reduces the need for manual labor, minimizes errors, and speeds up the production process. As a result, industries such as automotive manufacturing benefit from faster production times and lower labor costs, all while maintaining the high precision required for quality CNC Milled Parts.

Why Choose CNCRUSH for Your CNC Machining Needs?

At CNCRUSH, we pride ourselves on offering top-quality CNC Machining Services to clients across the globe. With over 12 years of experience in CNC milling and turning, we specialize in producing CNC Milled Parts and CNC Turned Parts for industries such as automotive, aerospace, and machine building. Our expert team ensures that every part meets the highest standards of precision and quality.

Whether you need CNC Milled Parts for automotive applications or CNC Turned Parts for machine building, CNCRUSH provides custom CNC solutions tailored to your exact specifications. With our state-of-the-art equipment and commitment to excellence, we offer cost-effective, high-quality CNC machining solutions to meet your needs.

Contact CNCRUSH today to discuss your project and discover how our CNC Machining Services can help you achieve your manufacturing goals.

Table 1: CNC Milling vs. Traditional Milling Comparison

| Feature | CNC Milling | Traditional Milling |

|---|---|---|

| Precision | High (up to microns) | Lower (depending on manual skill) |

| Production Speed | Fast and consistent | Slower, with more potential errors |

| Human Error | Minimal, automated | High, dependent on operator skill |

| Complexity of Parts | Complex geometries and 3D shapes possible | Limited to simpler parts |

| Cost Efficiency | Higher upfront cost but more cost-effective in bulk | Lower initial cost but less efficient for large-scale production |

Table 2: Industries Benefiting from CNC Milling

| Industry | Application Example | Importance of CNC Milling |

|---|---|---|

| Automotive | Engine blocks, suspension parts | High precision, durability, efficiency |

| Machine Building | Gears, shafts, custom components | Customization, part integration |

| Aerospace | Aircraft parts, fasteners | Extreme precision, reliability |

| Medical | Surgical tools, implants | Precision, safety, material versatility |

FAQ Section:

Q1: What is the difference between CNC milling and CNC turning?

- CNC milling involves rotating cutting tools to remove material from a workpiece, while CNC turning uses a rotating workpiece and stationary tools. CNC milling is ideal for producing complex, multi-dimensional parts, while CNC turning is used for creating cylindrical parts.

Q2: How do I choose the right CNC machining service for my project?

- When selecting a CNC machining service provider, consider their experience, machine capabilities, material expertise, and the industries they serve. CNCRUSH specializes in CNC Milled Parts and CNC Turned Parts and can offer tailored solutions for your specific needs.