CNC Machining plays a critical role in producing flywheels that enhance vehicle smoothness. Explore expert strategies, CNCRUSH’s CNC Milled parts and CNC Turned parts services, and how precision machining improves automotive, machine building, and automation performance.

Introduction

CNC Machining is the key to achieving high-precision flywheels that directly affect vehicle smoothness and engine efficiency. Flywheels must balance rotational energy, reduce vibrations, and maintain structural integrity under high stress. Proper CNC Machining of flywheels ensures minimal imbalance, smoother torque delivery, and enhanced engine longevity. Drawing insights from leading industry sources, this article explores eight critical strategies for improving vehicle smoothness through CNC Machining. CNCRUSH, a Chinese-based factory with 12 years of experience, specializes in CNC machining service for CNC Milled parts and CNC Turned parts, serving automotive, machine building, and automation industries worldwide.

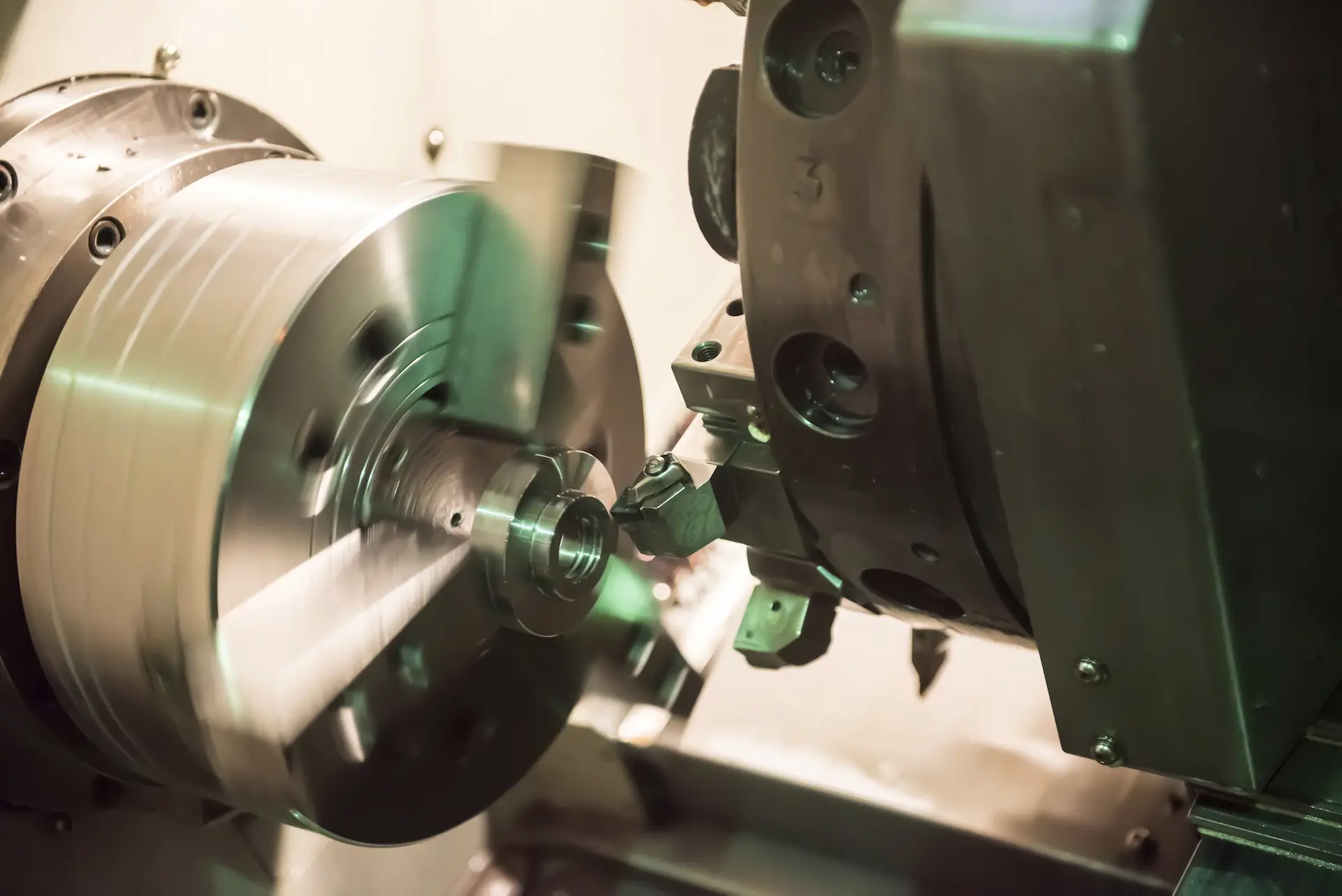

1. CNC Machining Service: Foundation of Flywheel Precision

CNC Machining Service enables the creation of flywheels with tight tolerances, precise diameters, and concentricity. CNCRUSH ensures that both CNC Milled parts and CNC Turned parts meet stringent performance criteria for automotive engines and heavy machinery.

Positive sentiment: Precise CNC Machining Service significantly reduces vibration and improves operational smoothness.

Table 1: CNC Machining Tolerances for Flywheels

| Component | Tolerance (mm) | Surface Finish (Ra µm) |

|---|---|---|

| CNC Turned Flywheel | ±0.005 | 0.2–0.4 |

| CNC Milled Features | ±0.01 | 0.4–0.8 |

| Dynamic Balancing | ±0.002 | – |

2. Material Selection for Vibration-Free Performance

Material choice impacts rotational inertia, wear resistance, and vibration absorption. Cast iron, steel, and aluminum alloys each offer unique benefits. CNCRUSH carefully selects materials to optimize both CNC Milled parts and CNC Turned parts for automotive, machine building, and automation applications.

Positive sentiment: High-quality materials lead to smoother, more reliable engine operation.

3. Dimensional Accuracy in CNC Turning

Flywheels require tight diameter and thickness tolerances. Even minor deviations can induce vibrations or reduce energy storage efficiency. CNCRUSH employs advanced CNC Turning and measurement tools to ensure that CNC Turned parts achieve exact specifications.

4. Surface Finish: Reducing Friction and Noise

Flywheel surface finish affects clutch engagement, noise levels, and friction. CNC Machining allows ultra-smooth surfaces, enhancing the interaction between flywheels and other engine components. CNCRUSH’s CNC Milled parts and CNC Turned parts are finished to optimal Ra values for superior performance.

5. Balancing Flywheels for Maximum Smoothness

Dynamic balancing minimizes rotational vibration, which directly affects vehicle smoothness. CNCRUSH integrates balancing processes with CNC Turning Service, ensuring that each CNC Turned part operates flawlessly in automotive, machine building, and automation systems.

Table 2: Recommended Flywheel Balancing Standards

| Flywheel Type | Max Allowable Unbalance (g·mm) | Surface Finish (Ra µm) |

|---|---|---|

| Automotive | 3 | 0.4–0.6 |

| Heavy Equipment | 5 | 0.6–0.8 |

| Industrial | 10 | 0.8–1.0 |

6. Heat Treatment for Durability

Heat treatment enhances hardness and fatigue resistance, critical for flywheels subjected to high torque. Quenching and tempering are applied to CNC Turned parts and CNC Milled parts, ensuring long-lasting durability in automotive and industrial machinery.

Positive sentiment: Proper heat treatment reduces the risk of cracks and deformation under stress.

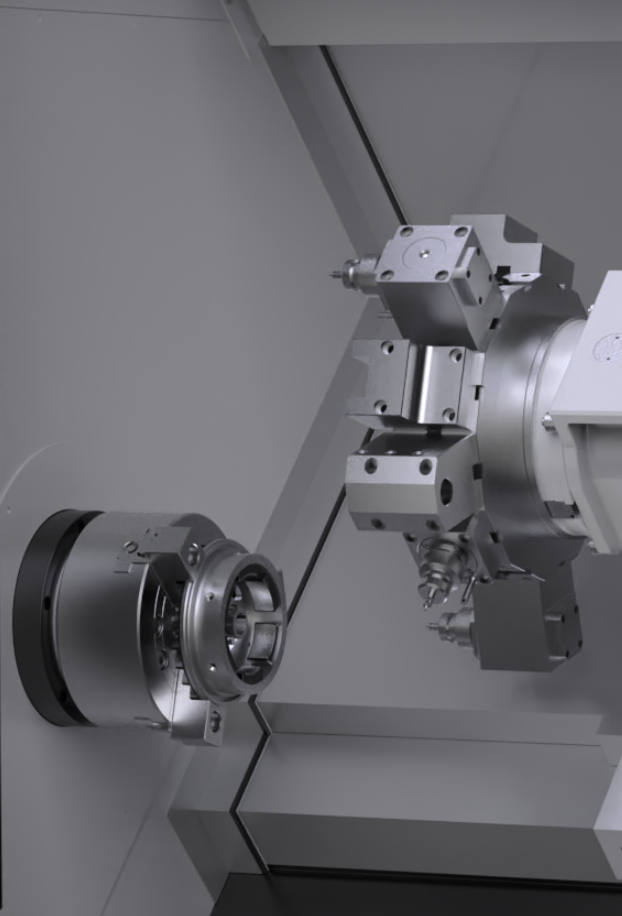

7. CNC Machining for Large-Diameter Flywheels

Handling large flywheels requires specialized CNC Turning equipment with rigid spindles and high-power motors. CNCRUSH’s advanced CNC machinery can process oversized components while maintaining tight tolerances and surface finishes, ensuring smooth operation.

Negative sentiment: Poor CNC machining of large flywheels can result in imbalance, vibration, and engine wear.

8. Challenges and Solutions in Flywheel CNC Machining

Common challenges include thermal expansion, tool deflection, and maintaining concentricity. CNCRUSH overcomes these challenges using high-rigidity machines, advanced toolpath planning, and real-time monitoring, delivering CNC Milled parts and CNC Turned parts that meet stringent automotive standards.

9. Integration with Automotive, Machine Building, and Automation

Flywheels interact with engines, transmissions, and industrial machinery. CNCRUSH’s CNC Machining Service ensures precise fit, optimal rotational inertia, and smooth torque delivery. Both CNC Milled parts and CNC Turned parts are crafted to enhance overall system performance.

10. Future Trends in Flywheel CNC Machining

The trend toward lightweight, high-strength flywheels continues. Innovations in multi-axis CNC Machining, adaptive toolpaths, and material engineering will further improve smoothness and durability. CNCRUSH stays at the forefront, offering CNC Milled parts and CNC Turned parts for next-generation automotive and industrial applications.

FAQ

Q1: What is the difference between CNC Milled parts and CNC Turned parts in flywheel production?

A1: CNC Milled parts are created by cutting stationary workpieces with rotary tools, while CNC Turned parts are produced by rotating the workpiece against a cutting tool. Both are critical for high-precision flywheels.

Q2: Why is flywheel balancing essential for vehicle smoothness?

A2: Proper balancing minimizes vibration and noise, ensuring smoother engine operation and better torque delivery.

Q3: Can CNCRUSH handle both small and large-scale flywheel orders?

A3: Yes. CNCRUSH provides scalable CNC Machining Service, producing high-quality CNC Milled parts and CNC Turned parts for automotive, machine building, and automation industries.