In the fast-paced world of manufacturing, efficiency is key to staying competitive and profitable. CNC machining has revolutionized metalworking industries by offering unmatched precision, consistency, and speed. At CNCRUSH, a factory based in China specializing in CNC machining services for over 12 years, we have seen firsthand how CNC technology enhances production efficiency, particularly in sectors like automotive, machine building, and automation.

This article delves into 10 powerful ways CNC machining improves efficiency in metalworking and how businesses can leverage this technology for Pièces fraisées CNC et Pièces tournées CNC production. Que vous cherchiez à rationaliser vos opérations ou à réduire vos coûts de fabrication, l'usinage CNC offre une multitude d'avantages qui peuvent faire une différence significative. En comprenant ces stratégies, vous serez mieux équipé pour prendre des décisions éclairées concernant l'intégration Services d'usinage CNC into your workflow.

1. Precision and Consistency in CNC Machining

The most significant advantage of CNC machining is its ability to deliver Usinage CNC de précision at scale. In industries like automotive and machine building, tight tolerances are essential. CNC machines can repeat the same operations with millimeter or even micrometer precision, ensuring consistent quality across high volumes of parts.

By automating the machining process, businesses can reduce human error, minimize scrap, and produce parts that meet exact specifications. At CNCRUSH, we specialize in producing Pièces fraisées CNC et Pièces tournées CNCen garantissant que chaque pièce correspond à la conception du client. Qu'il s'agisse de composants complexes pour le secteur automobile ou de pièces de précision pour les machines industrielles, Services d'usinage CNC ensure the highest level of accuracy in every operation.

2. Faster Production Times with CNC Machining

Time is money in manufacturing, and CNC machining accelerates production speeds without compromising quality. Unlike traditional machining, which requires manual input for each step, Usinage CNC is programmed to perform a series of tasks automatically. This significantly reduces cycle times, increases throughput, and allows for the production of large quantities of parts within shorter periods.

At CNCRUSH, we’ve seen how the efficiency of Pièces tournées CNC et Pièces fraisées CNC has boosted production for our clients. By utilizing the full potential of CNC technology, we are able to meet tight deadlines and handle large orders with ease.

3. Cost Savings through Automation

Services d'usinage CNC reduce labor costs by minimizing the need for manual intervention in the manufacturing process. With CNC technology, fewer operators are needed, and many manual processes like tool changes, measuring, and adjustments are automated. This translates into significant savings in terms of labor costs.

Additionally, by reducing the number of mistakes and defects, CNC machining minimizes waste and scrap, further reducing overall production costs. For companies in the automotive or machine building industries, this means Pièces fraisées CNC et Pièces tournées CNC can be produced at a lower cost per unit, without sacrificing quality.

4. Flexibility for Customization and Complex Geometries

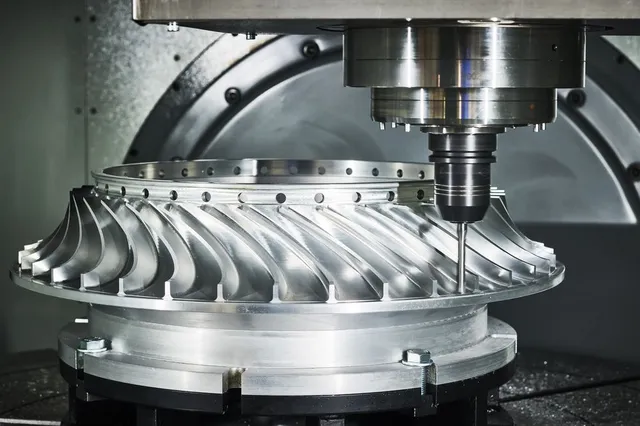

Another key advantage of CNC machining is its flexibility in producing complex shapes and geometries. Traditional methods often struggle with intricate designs or require multiple steps, but Usinage CNC can handle complex contours and features in a single setup.

At CNCRUSH, we work with a range of industries, including automobile, construction de machines, et automation, fournissant solutions CNC personnalisées tailored to specific needs. Whether it’s a complex component for a high-performance machine or a custom part for a vehicle, CNC technology enables us to deliver on-time, high-quality results.

5. Increased Capacity for High-Volume Production

CNC machines are built for high-volume production runs, making them ideal for industries that require large quantities of parts. With Usinage CNC, manufacturers can run machines continuously, 24/7, without the need for breaks, leading to greater efficiency and throughput.

In our experience at CNCRUSH, Pièces fraisées CNC et Pièces tournées CNC are often produced in high volumes for clients in the automobile et construction de machines industries. The automated nature of CNC technology allows us to keep production lines running at maximum capacity, meeting the demands of our clients for high-volume, high-quality parts.

6. Enhanced Material Utilization

CNC machining not only improves the quality of finished parts but also maximizes material utilization. Traditional machining processes often lead to significant material waste, but Usinage CNC is more efficient in using raw materials, especially for parts like Pièces fraisées CNC et Pièces tournées CNC.

By using precise cutting and programming, CNC machines ensure that the most material is used effectively. This reduces the amount of waste produced, which is especially important in industries like automotive manufacturing, where materials like aluminum, steel, and brass are commonly used.

7. Minimal Downtime and Maintenance

One of the most compelling benefits of CNC machining is its ability to operate with minimal downtime. CNC machines are highly reliable and require less maintenance compared to manual machines, which often experience wear and tear. Additionally, the automation of CNC machines reduces the likelihood of unexpected stoppages due to human error.

At CNCRUSH, we ensure that our Pièces tournées CNC et Pièces fraisées CNC production lines are constantly monitored and maintained, minimizing any downtime and ensuring timely deliveries for clients in industries like construction de machines et automobile.

8. Improved Supply Chain Management

The integration of CNC machining into the supply chain improves overall logistics and inventory management. With Services d'usinage CNC, manufacturers can produce parts on demand, reducing lead times and the need for large inventory holdings. This flexibility allows businesses to react quickly to changes in demand and fulfill orders without delays.

For clients in industries like automobile ou automation, CNC machining provides a reliable source of parts, ensuring that their production lines are never held up due to supply chain disruptions. At CNCRUSH, we offer on-demand production of Pièces fraisées CNC et Pièces tournées CNC to ensure our clients have the parts they need, when they need them.

9. Superior Surface Finish and Quality Control

CNC machines are capable of producing parts with superior surface finishes, which is particularly important for industries like automotive, where aesthetics and functionality go hand-in-hand. The precise control over cutting tools allows for a smooth surface, which reduces the need for additional finishing operations.

Additionally, the integration of Usinage CNC with quality control tools, such as CMM (Coordinate Measuring Machines), ensures that every part produced meets strict standards. At CNCRUSH, we take quality seriously, using the latest CNC machining technology to ensure our Pièces fraisées CNC et Pièces tournées CNC exceed expectations.

10. Faster Time to Market

Finally, CNC manufacturing plays a critical role in reducing the time it takes to bring a product to market. By speeding up the manufacturing process, automating key tasks, and producing high-quality parts with precision, CNC manufacturing allows businesses to deliver products faster, giving them a competitive edge in industries where time-to-market is crucial.

At CNCRUSH, we understand the importance of speed. Whether you need Pièces fraisées CNC ou Pièces tournées CNC, we ensure your project is completed quickly, allowing you to meet deadlines and keep your production lines running smoothly.

Table 1: Key Advantages of CNC Machining in Metalworking

| Avantage | Avantage |

|---|---|

| Précision et exactitude | Delivers tight tolerances for high-quality parts |

| Temps de production réduit | Faster machining cycles improve throughput |

| Coûts de main-d'œuvre réduits | Less manual intervention required |

| Flexibilité | Capable of producing complex shapes and geometries |

| Production en grand volume | Ideal for large runs of parts, reducing time and cost per unit |

| Efficacité matérielle | Maximizes raw material usage, minimizing waste |

| Fiabilité | CNC machines have lower downtime and maintenance costs |

| Improved Quality Control | Integrated quality control ensures all parts meet strict standards |

| Faster Time to Market | Reduces production time, helping businesses meet deadlines |

Table 2: CNC Machining Applications in Various Industries

| Industrie | Applications |

|---|---|

| Automobile | Precision components, engine parts, chassis, suspension systems |

| Construction de machines | Structural parts, gears, shafts, fasteners, and housings |

| Automation | Custom parts for robotics, control systems, and conveyors |

| Aérospatial | Complex components, precision fittings, and structural parts |

| Dispositifs médicaux | Surgical tools, diagnostic equipment, prosthetics, and implants |

FAQ Section: CNC Machining and Its Benefits

Q1 : Qu’est-ce que l’usinage CNC ?

CNC machining refers to the process of using computer-controlled machines to create precise metal or plastic parts. It includes milling, turning, drilling, and other operations that result in custom, high-quality parts.

Q2: How does CNC manufacturing improve efficiency?

CNC machining improves efficiency by automating the production process, reducing manual labor, and minimizing errors. It allows for faster production times, higher precision, and cost savings in large-volume runs.

Q3: What industries benefit from CNC manufacturing?

Des industries comme automobile, construction de machines, aérospatial, et automation benefit from CNC machining due to its ability to produce high-quality, complex parts with precision.

Q4: Why choose CNCRUSH for CNC machining services?

Avec plus de 12 ans d'expérience dans Services d'usinage CNC, CNCRUSH est spécialisé dans Pièces fraisées CNC et Pièces tournées CNC for industries like automotive, machine building, and automation. Our expertise, commitment to quality, and competitive pricing make us a trusted partner for your CNC manufacturing needs.

Conclusion

CNC machining has transformed the metalworking industry by enhancing efficiency, reducing costs, and improving production timelines. By leveraging CNC technology, companies can deliver high-quality parts with precision, flexibility, and faster turnaround times. For those in need of Pièces fraisées CNC et Pièces tournées CNC, CNCRUSH offers services de fabrication CNC de haute qualité backed by over 12 years of experience. Visit us at CNCRUSH for expert solutions to meet your manufacturing needs.

Salut ! J'ai trouvé votre blog en utilisant msn. C'est un article vraiment bien écrit.

Je veillerai à le mettre dans les favoris et à revenir pour lire la suite de

Vos informations utiles. Merci pour le post. Je reviendrai certainement.