CNC Milling has revolutionized industries by offering unmatched precision, speed, and versatility. It has become the cornerstone of manufacturing complex and custom parts, particularly for small metal components. In this comprehensive guide, we will explore the many advantages of CNC milling for small metal parts, focusing on the automotive, machine building, and automation sectors. We will also highlight the importance of working with a specialized CNC machining service provider, such as CNCRUSH, a trusted China CNC factory with over 12 years of experience in the field.

CNC milling offers numerous benefits for the production of small metal parts, from enhanced precision and cost-effectiveness to scalability and material versatility. This article draws on insights from several industry-leading sources to present a complete analysis of CNC milling’s impact on small part manufacturing, with a special emphasis on its role in key industries such as automotive and automation. By choosing a CNC machining service, customers can ensure the best quality, efficiency, and turnaround times.

1. Precision and Accuracy: Why CNC Milling is the Best Option

CNC milling provides the highest level of precision and accuracy in metal part manufacturing. Using CAD models and computer-controlled operations, these machines can achieve tolerances as tight as 0.005 mm, ensuring every part meets exact specifications. The precision afforded by CNC milling is critical for industries like automotive and machine building, where even the slightest deviation can result in significant performance issues.

For CNC Milled parts, accuracy is non-negotiable, especially in high-stakes applications like engine components or robotic automation tools. For CNCRUSH, our precision CNC machining service ensures every part we manufacture meets these stringent demands.

Table 1: Common Tolerances for CNC Machined Metal Parts

| Industry | Tolerance Requirement | Common Material |

|---|---|---|

| Automotive | ± 0.01 – 0.02 mm | Steel, Aluminum |

| Automation | ± 0.005 – 0.015 mm | Brass, Stainless Steel |

| Machine Building | ± 0.01 mm | Steel, Titanium |

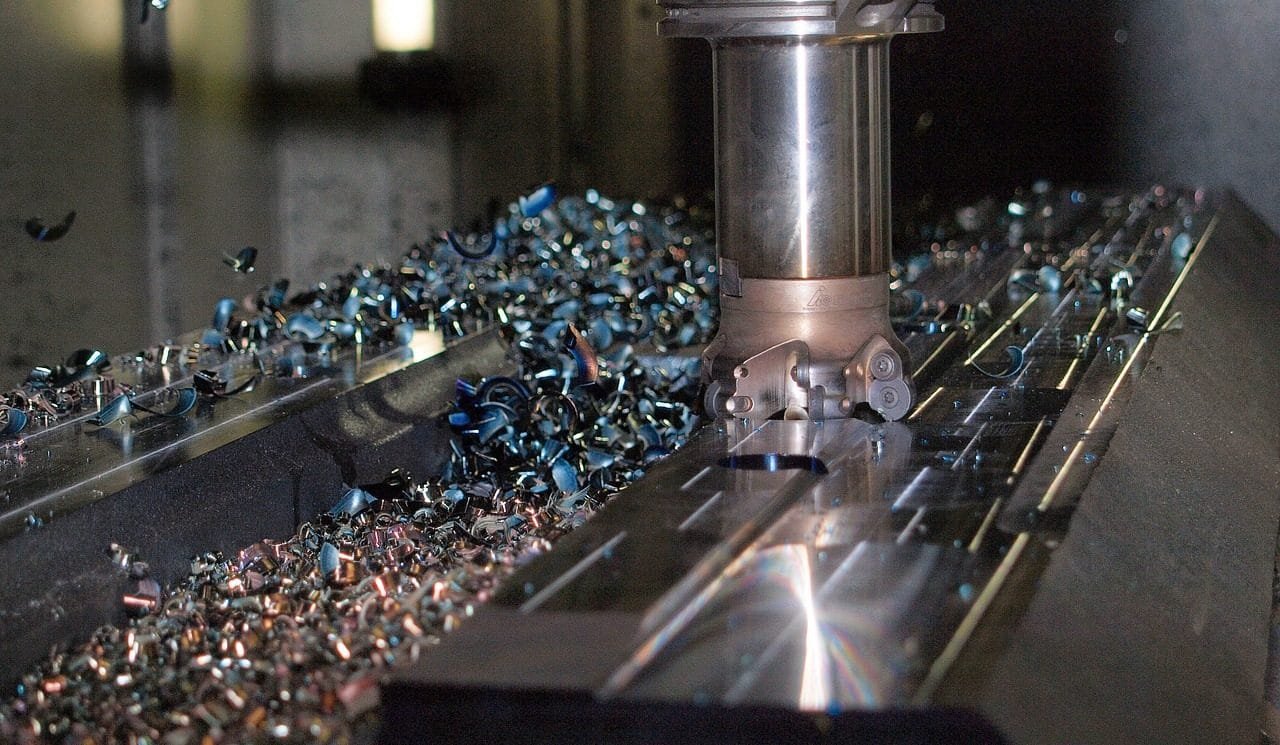

2. Reduced Material Waste: The Cost-Effectiveness of CNC Machining

One of the standout benefits of CNC milling is its ability to minimize waste. Through subtractive manufacturing, only the necessary amount of material is removed, ensuring minimal waste, which is particularly important when working with expensive metals like titanium or specialized alloys. Additionally, automated processes eliminate human error, further reducing scrap rates.

At CNCRUSH, our CNC machining service is designed with cost-efficiency in mind. We help clients cut costs by optimizing material usage without compromising on the quality of the final part.

3. Enhanced Production Speed: Meeting Tight Deadlines

CNC machines operate at incredibly high speeds, capable of running 24/7 with minimal supervision. This makes them an ideal solution for projects that require fast turnaround times. For example, in the automotive industry, where rapid prototyping and mass production are vital, CNC milling delivers both speed and precision.

CNCRUSH specializes in providing fast and reliable CNC Turned parts and CNC Milled parts for clients in various sectors, ensuring that we meet even the tightest production deadlines.

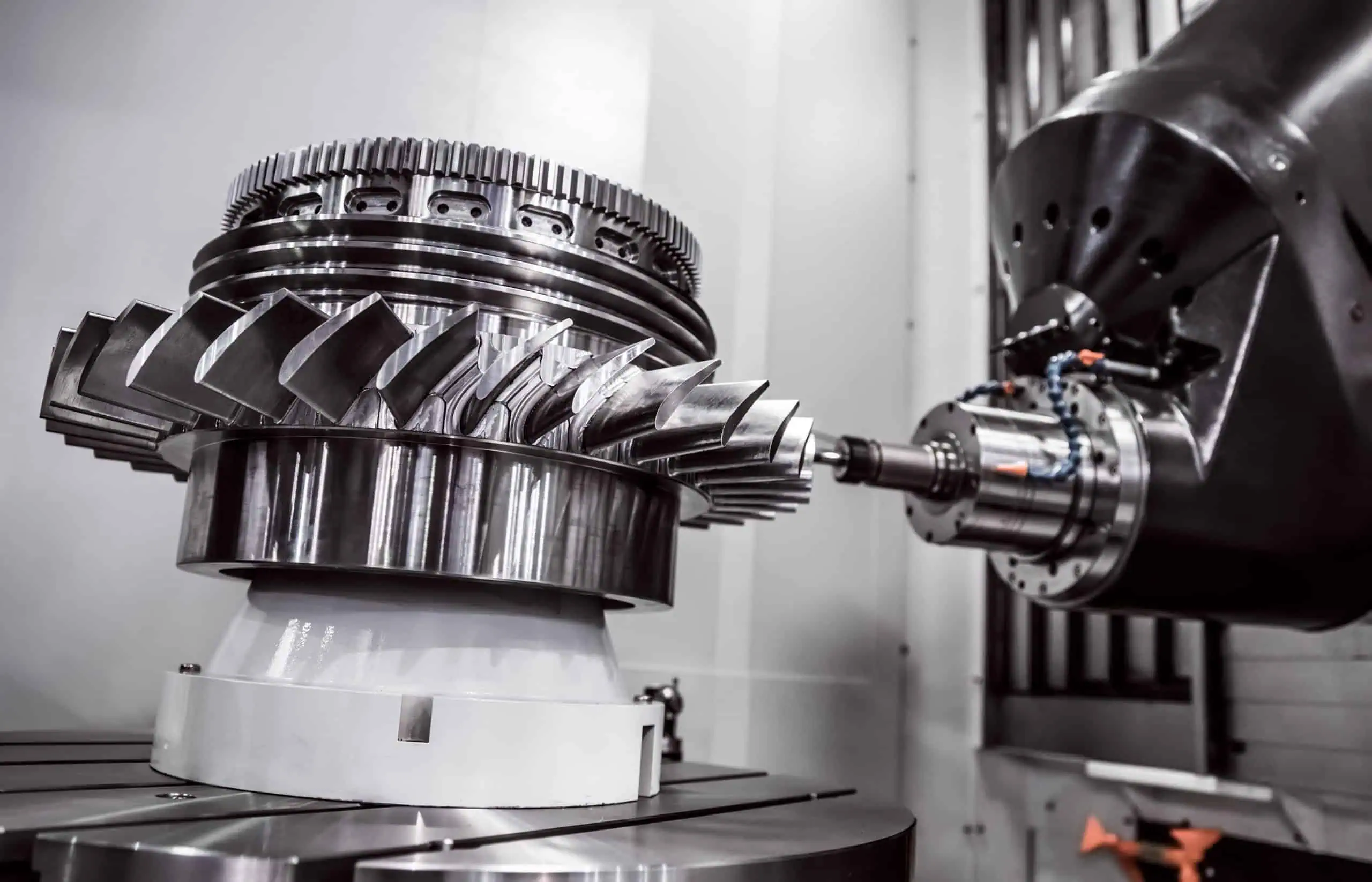

4. Complex Geometries: CNC Milling for Advanced Designs

CNC milling allows for the creation of complex geometries and intricate shapes that would be impossible to achieve with manual machining. Multi-axis CNC milling machines, such as 5-axis systems, can produce parts with complex contours and surfaces, making them invaluable in industries like aerospace and medical device manufacturing.

Our CNC machining service at CNCRUSH is particularly adept at producing intricate CNC Turned parts used in advanced mechanical systems, robotics, and automation technologies.

5. Scalability: From Prototypes to Mass Production

Another major advantage of CNC milling is its scalability. Whether you need a single prototype or thousands of parts, CNC milling machines can handle production runs of any size. This scalability ensures that CNC milling remains an efficient solution regardless of production volume, reducing setup times and maximizing output.

CNCRUSH has helped numerous clients scale their operations from prototype design to full production, providing custom CNC solutions tailored to meet their specific needs.

6. Versatile Material Compatibility: From Aluminum to Titanium

CNC milling is highly versatile when it comes to the types of materials that can be used. Whether working with aluminum, steel, brass, titanium, or plastics, CNC machines can handle a wide range of metals and other materials. This versatility makes CNC milling particularly beneficial for industries like automotive and aerospace, where different parts may require various materials.

CNCRUSH offers CNC machining aluminum as well as CNC machining steel, ensuring we can meet any material needs you may have for your project.

7. CNC Milling and Automation: Building the Future

The role of CNC milling in automation and machine building is critical. CNC machines can create highly specialized components for automation equipment, helping manufacturers build machines that improve productivity and accuracy in their own production processes.

With 12 years of experience, CNCRUSH is a trusted provider of CNC machined parts for clients in the automation industry, helping them design and build the future of manufacturing.

8. Improved Consistency and Repeatability

Manual machining can often lead to small variations between parts, but CNC milling ensures that every part is identical. This level of consistency is especially crucial in the automotive industry, where uniformity is critical for performance and safety.

With CNC Milled parts, CNCRUSH delivers consistent, high-quality results for every project, helping you avoid costly errors and product recalls.

9. Worker Safety: CNC Milling Reduces Risks

By automating the production process, CNC machining significantly reduces the risk of workplace accidents. Operators are kept at a safe distance from the cutting tools, which are fully enclosed and controlled by the machine’s computer system.

At CNCRUSH, we prioritize safety in our operations, ensuring that all CNC machining services are carried out with strict safety protocols.

10. Customization and Flexibility

CNC milling offers unmatched flexibility, allowing for rapid adjustments in the production process. Whether you need to make a small tweak to a design or switch to a different material, CNC milling provides the versatility required to meet changing demands.

Our CNC machining service at CNCRUSH allows clients to fully customize their orders, ensuring that every part is tailored to their specific application.

Table 2: Comparison of CNC Milling with Other Manufacturing Techniques

| Manufacturing Method | Material Versatility | Precision | Scalability | Cost Efficiency |

|---|---|---|---|---|

| CNC Milling | High | High | High | High |

| 3D Printing | Medium | Medium | Low | Medium |

| Injection Molding | Low | Medium | High | High (Large Scale) |

FAQ Section

Q1: What materials can be used in CNC machining?

CNC milling can handle a wide range of materials, including metals like aluminum, steel, titanium, and brass, as well as plastics such as ABS and PEEK.

Q2: How does CNC machining ensure accuracy?

CNC milling uses computer-controlled operations to execute precise movements and cutting, ensuring tight tolerances and repeatability for every part.

Q3: What industries benefit most from CNC machining?

Industries such as automotive, machine building, aerospace, automation, and medical device manufacturing greatly benefit from CNC machining due to the need for precision, scalability, and material versatility.

In conclusion, CNC machining is an invaluable technology for producing small metal parts, offering advantages like precision, speed, material versatility, and scalability. Whether you need custom prototypes or mass-produced components, CNCRUSH’s CNC machining service can provide the high-quality, precision-made parts you need to succeed in industries ranging from automotive to automation. Contact us today for more information on how our expertise can help you optimize your production processes.