CNC Machining plays a critical role in ensuring heat and wear resistance in valve seat manufacturing, directly influencing engine efficiency, durability, and performance in automotive, machine building and automotion industries.

Valve seat materials, machining strategies, and precision processes are no longer just engineering choices—they define reliability, safety, and long-term operational costs. This article consolidates insights from industry leaders, academic research, and CNCRUSH’s 12-year CNC machining service experience to provide actionable guidance on producing high-performance valve seats with superior heat and wear resistance.

Executive Summary: What the Industry Teaches About Heat and Wear Resistance in Valve Seat CNC Machining

Global research and case studies emphasize the critical importance of material selection, cutting strategies, and tool management in CNC Machining for valve seats. Key observations include:

-

High thermal conductivity materials reduce localized overheating.

-

Hardened and coated valve seat inserts improve wear resistance.

-

CNC Milled parts and CNC Turned parts require process-specific parameters to maintain tolerances under thermal stress.

-

Surface finish and microgeometry directly affect sealing efficiency and wear life.

CNCRUSH applies these principles in our CNC machining service for both automotive and industrial clients, delivering reliable CNC Milled parts and CNC Turned parts for over 12 years.

1. CNC Machining for Valve Seats – Why Heat Resistance Matters

High combustion temperatures in modern engines demand that valve seats withstand extreme heat without distortion or loss of sealing ability. Poor CNC Machining leads to negative outcomes like:

-

Micro-cracking

-

Loss of concentricity

-

Premature wear

CNCRUSH mitigates these risks by controlling tool engagement, cutting speed, and thermal load during CNC Milled parts and CNC Turned parts production. Positive results include consistent tolerances and long-lasting engine reliability.

2. CNC Machining Service Material Selection for Maximum Wear Resistance

Material choice dramatically impacts valve seat longevity. Common options include:

-

High-carbon steels

-

Powdered metal inserts

-

Cobalt or nickel alloys

-

PTFE or Teflon for specialty plastic seats

Each material requires tailored CNC Machining strategies. For example, hard alloy inserts benefit from CNC Turning for concentricity, while complex angles require CNC Milling. CNCRUSH leverages 12 years of experience to optimize cutting parameters for these materials.

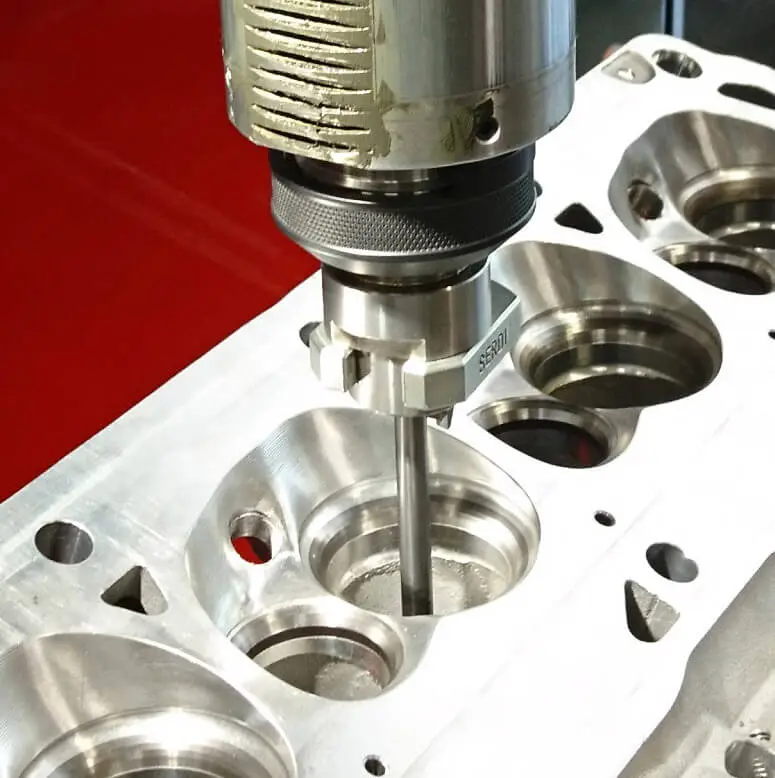

3. CNC Machining and the Role of CNC Milled Parts in Surface Finish

Surface finish is a critical determinant of valve seat wear. Rough surfaces accelerate erosion and carbon buildup, a negative factor affecting performance. CNC Milled parts provide:

-

Controlled feed rates

-

Precision multi-axis cutting

-

Minimal micro-tearing

By producing highly consistent surfaces, CNCRUSH ensures superior heat transfer and longer service life for valve seats.

4. CNC Machining and the Role of CNC Turned Parts in Concentricity

Valve seat roundness is vital for sealing. CNC Turned parts excel in controlling:

-

Concentricity

-

Circularity

-

Dimensional repeatability

Our CNC machining service integrates turning with milling to maintain overall geometric integrity, critical in automotive and machine building applications.

5. Tooling Strategies in CNC Machining Service for Heat and Wear Resistance

Cutting tools define process success. Negative outcomes, such as chatter and premature wear, are often due to inadequate tool choice. CNCRUSH focuses on:

-

High-rigidity inserts

-

Coated tools for heat resistance

-

Tool life monitoring systems

Proper tooling reduces maintenance cost while improving valve seat durability.

6. CNC Machining Process Optimization for Automotive and Automotion Applications

High-volume production demands stable processes. CNCRUSH optimizes CNC Machining workflows to balance:

-

Feed and speed

-

Tool wear compensation

-

Thermal expansion control

Positive sentiment: Enhanced reliability and repeatable quality increase client satisfaction and reduce scrap rates.

7. Heat Treatment Considerations and CNC Machining Integration

Pre- and post-machining heat treatments improve wear resistance. CNC manufacturing must account for:

-

Material hardness changes

-

Dimensional shrinkage

-

Tool path adjustments

CNCRUSH integrates heat treatment considerations into both CNC Milled parts and CNC Turned parts production.

8. CNC Machining Monitoring and Quality Control

Continuous monitoring prevents negative outcomes such as warping or improper seating. Techniques include:

-

In-process probing

-

Optical inspection

-

CMM verification

For CNC Turned parts, concentricity errors are detected early, ensuring consistent performance.

9. Cost vs. Performance Analysis in CNC Machining Service

High-precision CNC manufacturing can seem costly, but poor execution results in even higher expenses due to:

-

Component failures

-

Rework

-

Scrap parts

CNCRUSH balances cost and performance by leveraging optimized CNC Milled parts and CNC Turned parts strategies.

10. Why CNCRUSH is Your Trusted CNC Machining Service Partner

CNCRUSH offers:

-

12 years of CNC machining service experience

-

Expertise in CNC Milled parts and CNC Turned parts

-

Serving automotive, machine building and automotion industries globally

-

High-precision, reliable, and scalable solutions

Choosing CNCRUSH ensures consistent heat and wear resistance for every valve seat project.

Comparative Analysis Table: Valve Seat Materials and Heat Resistance

| Material Type | Hardness | Thermal Conductivity | Wear Resistance | Recommended CNC Machining Approach |

|---|---|---|---|---|

| Alloy Steel | HRC 50-55 | Moderate | High | CNC Turning + Milling |

| Powdered Metal | HRC 55-60 | High | Very High | CNC Milling + Coated Tools |

| PTFE / Teflon | N/A | Low | Moderate | Low-Force CNC Milling |

| Nickel Alloy | HRC 60+ | High | Very High | CNC Turning with Tool Life Monitoring |

CNC Milled Parts vs CNC Turned Parts for Heat and Wear Resistance

| Feature | CNC Milled Parts | CNC Turned Parts |

|---|---|---|

| Surface Finish | High-quality angles & transitions | Concentric, round features |

| Heat Management | Controlled cutting heat | Stable thermal expansion |

| Wear Resistance | Smooth contact surfaces | Accurate geometry for long-term sealing |

| Key Application | Seat surfaces, complex profiles | Inserts, rings, cylindrical sections |

FAQ: CNC Machining of Valve Seats

Q1: Why is heat resistance crucial in valve seat CNC Machining?

High temperatures can deform seats, causing leaks, wear, and engine inefficiency.

Q2: Can one process produce both CNC Milled parts and CNC Turned parts?

Typically, high-performance seats require a combination of both processes.

Q3: How does CNCRUSH ensure consistent wear resistance?

Through 12 years of CNC manufacturing service experience, optimized cutting parameters, and stringent QC.

Q4: Are plastic valve seats viable for automotive use?

For specific low-load or chemical-resistant applications, yes—using CNC Milled parts with PTFE or Teflon.

Q5: Why choose CNCRUSH as a CNC machining service provider?

Because we deliver reliable, precise, and durable components with global-quality standards at competitive cost.

Final Thoughts: CNC Machining as a Strategic Asset for Valve Seats

Precision CNC Machining is more than a manufacturing step—it is a strategic advantage. Proper execution ensures:

-

Heat resistance under extreme engine loads

-

Long-term wear performance

-

Reliable sealing and combustion efficiency

For high-quality CNC Milled parts and CNC Turned parts in automotive, machine building and automotion, CNCRUSH provides over 12 years of expertise and a trusted global reputation.