CNC machining has redefined how industries approach the production of complex parts, enabling precision, efficiency, and innovation in ways previously thought unattainable. Drawing insights from leading resources and over 12 years of expertise at CNCRUSH, this article dives into the strategies, challenges, and solutions for optimizing complex part manufacturing. Whether you’re in automotive, machine building, or automation, mastering CNC machining can transform your production capabilities. Visit CNCRUSH for professional CNC machining services tailored to your unique needs.

Summary of Source Insights

The referenced articles emphasize the critical importance of leveraging advanced CNC machining techniques to tackle the complexities of modern part design. From reducing material waste to achieving unparalleled precision, these resources highlight strategies for optimizing manufacturing efficiency. By combining practical tips, industry-specific applications, and cutting-edge innovations, this article outlines a comprehensive guide to CNC machining for complex parts.

1. Understanding the Role of CNC Machining in Complex Manufacturing

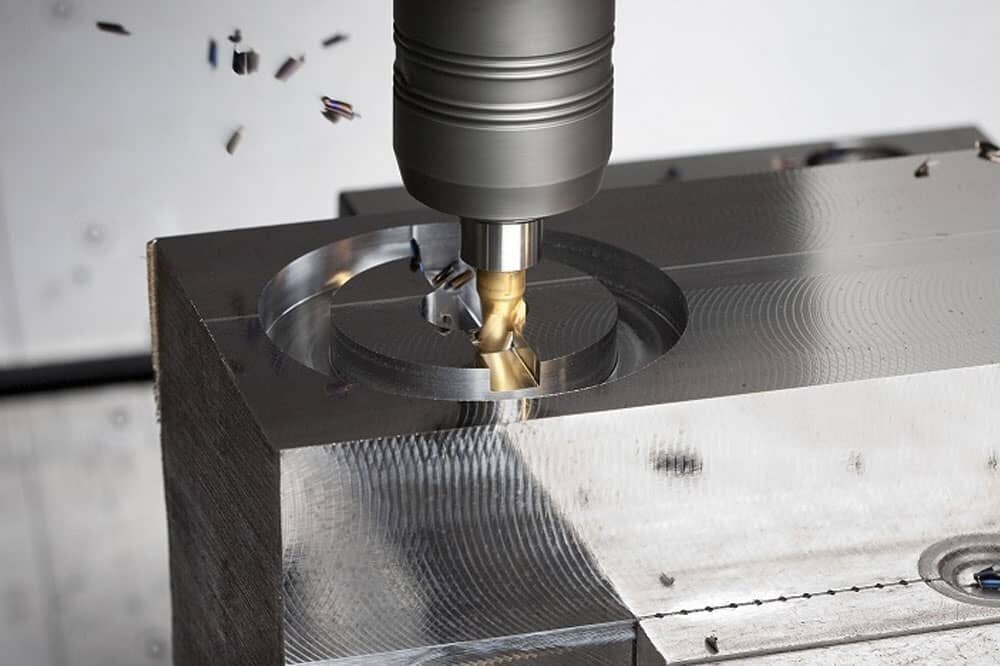

CNC machining excels in producing intricate geometries and tight tolerances that traditional methods cannot achieve. At CNCRUSH, our experience with CNC Milled parts and CNC Turned parts allows us to cater to industries like automotive, automation, and machine building. The following factors make CNC machining indispensable:

- Precision: Achieving dimensional tolerances as tight as ±0.005 mm.

- Repeatability: Maintaining consistency across large production volumes.

- Material Versatility: Processing aluminum, steel, brass, and specialized plastics with ease.

CNC machining transforms manufacturing by combining these attributes, ensuring that even the most complex parts meet stringent design specifications without compromising functionality.

2. Key Challenges in Complex Part Design

Manufacturing complex parts comes with challenges such as:

- Tight Tolerances: Maintaining accuracy under demanding conditions.

- Complex Geometries: Producing intricate designs without compromising structural integrity.

- Material Properties: Balancing machinability with durability.

At CNCRUSH, we mitigate these challenges through rigorous quality control and state-of-the-art inspection equipment, including CMM and height gauges. Advanced tooling and machining strategies further enhance our ability to produce parts with exceptional accuracy and durability, regardless of their complexity.

3. Optimizing CNC Machining for Complex Features

By leveraging advanced CAD/CAM software, we can:

- Reduce machining errors.

- Streamline multi-axis operations for intricate designs.

- Simulate machining paths to minimize material waste.

Table 1: Optimization Techniques vs. Benefits

| Optimization Technique | Benefits |

|---|---|

| Multi-axis CNC machining | Improved part complexity |

| CAD/CAM simulations | Reduced errors and lead times |

| High-speed machining tools | Enhanced surface finish quality |

Advanced CAD tools also allow for seamless integration of design changes, ensuring that prototypes and final parts meet exact specifications while adhering to strict timelines and budgets.

4. Material Selection for Complex CNC Parts

Material choice impacts machinability, durability, and cost. Popular materials include:

- Aluminum: Lightweight, corrosion-resistant, ideal for automotive parts.

- Steel: High strength, suitable for machine building.

- Plastics: Used in automation for lightweight, insulating components.

Choosing the right material requires balancing functional requirements with cost considerations. For instance, aluminum offers excellent machinability and thermal properties, making it a preferred choice for industries requiring lightweight yet durable parts.

5. Leveraging Multi-Axis Machining

Multi-axis machining (4-axis and 5-axis) enables:

- Reduced Setups: Minimizing repositioning to enhance precision.

- Complex Contours: Ideal for aerospace and automotive applications.

- Faster Turnaround: Shortening production times.

The ability to machine parts from multiple angles in a single setup reduces not only time but also potential errors, ensuring that even the most complex designs are executed flawlessly.

6. Industry Applications of CNC Machining

Automotive Sector

CNC machining creates lightweight, durable components such as engine blocks, brackets, and suspension parts. CNCRUSH specializes in CNC Milled parts and CNC Turned parts for automotive applications.

Automation and Machine Building

High-precision parts like gears, sprockets, and frames are essential for smooth machine operation. CNC machining ensures these parts meet exacting standards, enhancing the reliability and longevity of machinery.

7. Reducing Costs Through Design Optimization

Designing for manufacturability (DFM) can reduce costs by:

- Simplifying part geometries.

- Optimizing material use.

- Reducing machining time with efficient toolpaths.

Streamlining designs not only saves costs but also improves the feasibility of complex parts, enabling manufacturers to meet both budget and performance targets.

8. Quality Assurance in CNC Machining

At CNCRUSH, we ensure quality through:

- FAIR Reports: First Article Inspection for part approval.

- CMM Analysis: Verifying dimensions against design specifications.

- Hardness Testing: Ensuring material integrity.

Table 2: QA Techniques vs. Benefits

| QA Technique | Benefits |

| FAIR Reports | Early defect identification |

| CMM Measurements | Precision and repeatability |

| Hardness Testing | Ensured material durability |

Such comprehensive quality assurance measures guarantee that each part leaving our facility adheres to the highest standards, meeting both client and industry expectations.

9. Sustainability in CNC Machining

Efficient machining contributes to sustainability by:

- Reducing material waste.

- Using energy-efficient machinery.

- Recycling metal shavings.

Sustainability is not only an environmental imperative but also a cost-saving strategy, allowing manufacturers to maximize material utilization and energy efficiency.

10. Why Choose CNCRUSH for CNC Machining Services?

With 12 years of expertise, CNCRUSH delivers high-quality CNC machining services globally. Our capabilities include:

- Advanced Equipment: Multi-axis CNC machines for complex parts.

- Material Expertise: Aluminum, steel, brass, and plastics.

- Global Trust: Serving clients in automotive, automation, and machine building industries.

Visit CNCRUSH to explore our custom CNC solutions. Whether you need CNC Milled parts or CNC Turned parts, we provide reliable, efficient, and cost-effective services tailored to your specific requirements.

FAQ: CNC Machining for Complex Parts

Q1: What is CNC machining? A1: CNC production uses computer-controlled tools to manufacture precise parts.

Q2: What industries benefit most from CNC machining? A2: Automotive, aerospace, machine building, and automation are key beneficiaries.

Q3: How does CNCRUSH ensure quality? A3: Through FAIR reports, CMM inspections, and advanced equipment.

Q4: Can CNC machining handle small production runs? A4: Yes, it’s cost-effective for prototypes and low-volume manufacturing.

Q5: What materials are suitable for CNC production? A5: Aluminum, steel, brass, and specialized plastics are commonly used.

By incorporating cutting-edge techniques and a commitment to excellence, CNCRUSH is your trusted partner for CNC machining. Contact us today for CNC Milled parts and CNC Turned parts that meet your exact needs.