CNC machining is a revolutionary technology that has dramatically transformed manufacturing processes, offering unmatched precision, efficiency, and versatility. Industries such as automotive, machine building, and automation have seen profound advancements in productivity due to the adoption of CNC machining. This technology eliminates many inefficiencies of traditional manufacturing and sets new standards for speed, quality, and cost-effectiveness.

For over 12 years, CNCRUSH has provided world-class CNC machining services, specializing in CNC Milled parts and CNC Turned parts from our advanced facility in China. This article explores 10 transformative ways CNC machining boosts productivity, offering detailed insights into its benefits and inviting you to partner with CNCRUSH for your manufacturing needs.

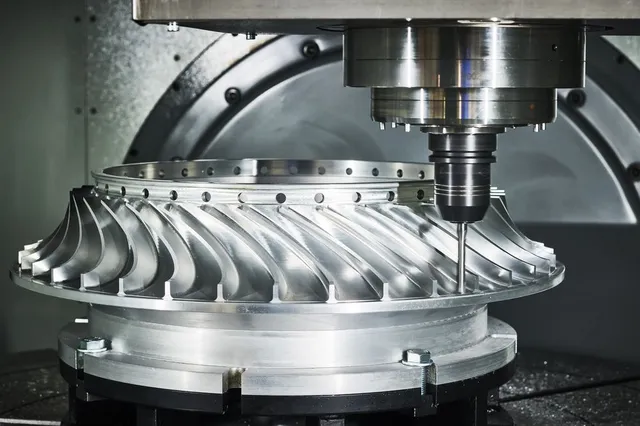

1. CNC Machining: A Precision Revolution

CNC machining achieves precision levels that traditional methods simply cannot match. With tolerances as tight as ±0.001 mm, it guarantees consistency across every unit produced, whether it’s a single prototype or a large-scale batch.

Why Precision Matters

- Industries like automotive demand exact specifications for components such as engine parts and gear mechanisms to ensure reliability and safety.

- Machine building relies on precision for components like bearings, housings, and frames that must fit seamlessly.

At CNCRUSH, we excel at manufacturing high-precision CNC Milled parts and CNC Turned parts, enabling our clients to maintain their competitive edge.

2. Efficient Production with CNC Machining Services

Efficiency is the cornerstone of productivity, and CNC manufacturing is built for it. Automated systems can operate around the clock with minimal human intervention, enabling rapid production without sacrificing quality.

Key Benefits of Efficiency in CNC manufacturing

- Shorter Production Times: Advanced programming reduces machine setup time and accelerates production cycles.

- 24/7 Operations: Unlike manual machining, CNC machines can function continuously with little downtime.

Our CNC machining services at CNCRUSH are designed to deliver on this promise, helping clients in the automation and automotive sectors scale their operations efficiently.

| Traditional Machining | CNC Machining |

|---|---|

| High labor involvement | Minimal labor, high automation |

| Longer production cycles | Rapid, precise production |

| Risk of human error | Consistent results through automation |

3. Unmatched Material Versatility

CNC manufacturing works with a wide array of materials, including aluminum, steel, brass, and plastics, making it adaptable for diverse industries. This flexibility opens new possibilities for lightweight components in automotive applications or durable parts in machine building.

Material-Specific Advantages

- CNC Machining Aluminum: Lightweight, corrosion-resistant, ideal for aerospace and automotive.

- CNC Machining Steel: Durable, heat-resistant, widely used in heavy machinery.

- CNC Plastic Machining: Flexible and lightweight, perfect for custom prototypes and electrical housings.

By partnering with CNCRUSH, you gain access to expertise across these materials, ensuring optimal solutions for your specific needs.

4. Streamlining Prototyping with CNC Machining

Rapid prototyping is critical for reducing time-to-market in competitive industries. CNC manufacturing excels in this domain by enabling fast and precise production of prototype components.

Prototyping with CNC Machining

- Iterative Design Improvements: Prototypes can be quickly revised based on testing results.

- Scalable Production: Once a prototype is approved, CNC machines can seamlessly transition to full-scale production.

At CNCRUSH, we specialize in CNC prototype machining, ensuring your designs move smoothly from concept to reality.

5. Sustainability Through Efficiency and Waste Reduction

CNC machining is not only efficient but also environmentally conscious. Advanced programming reduces waste by optimizing cutting paths and maximizing material use.

Sustainability Benefits

- Reduced Scrap: CNC machining’s precision ensures minimal material wastage.

- Energy Efficiency: Modern CNC machines consume less energy compared to traditional methods.

At CNCRUSH, we integrate sustainability into every project, ensuring resource efficiency while delivering top-tier CNC manufacturing services.

| Sustainability Metric | Traditional Machining | CNC Machining |

|---|---|---|

| Material Waste | High | Low |

| Energy Use | Moderate to High | Low to Moderate |

| Carbon Footprint | Significant | Reduced |

6. Automation Unlocks Labor Optimization

CNC machining eliminates much of the labor-intensive effort required in traditional methods, allowing manufacturers to reallocate skilled workers to more strategic roles.

Advantages of Automation

- Reduced Overhead Costs: Fewer operators are needed, lowering labor costs.

- Consistent Productivity: Automation enables machines to perform repetitive tasks without fatigue or errors.

With our state-of-the-art China CNC factory, CNCRUSH combines automation with human expertise to deliver exceptional results.

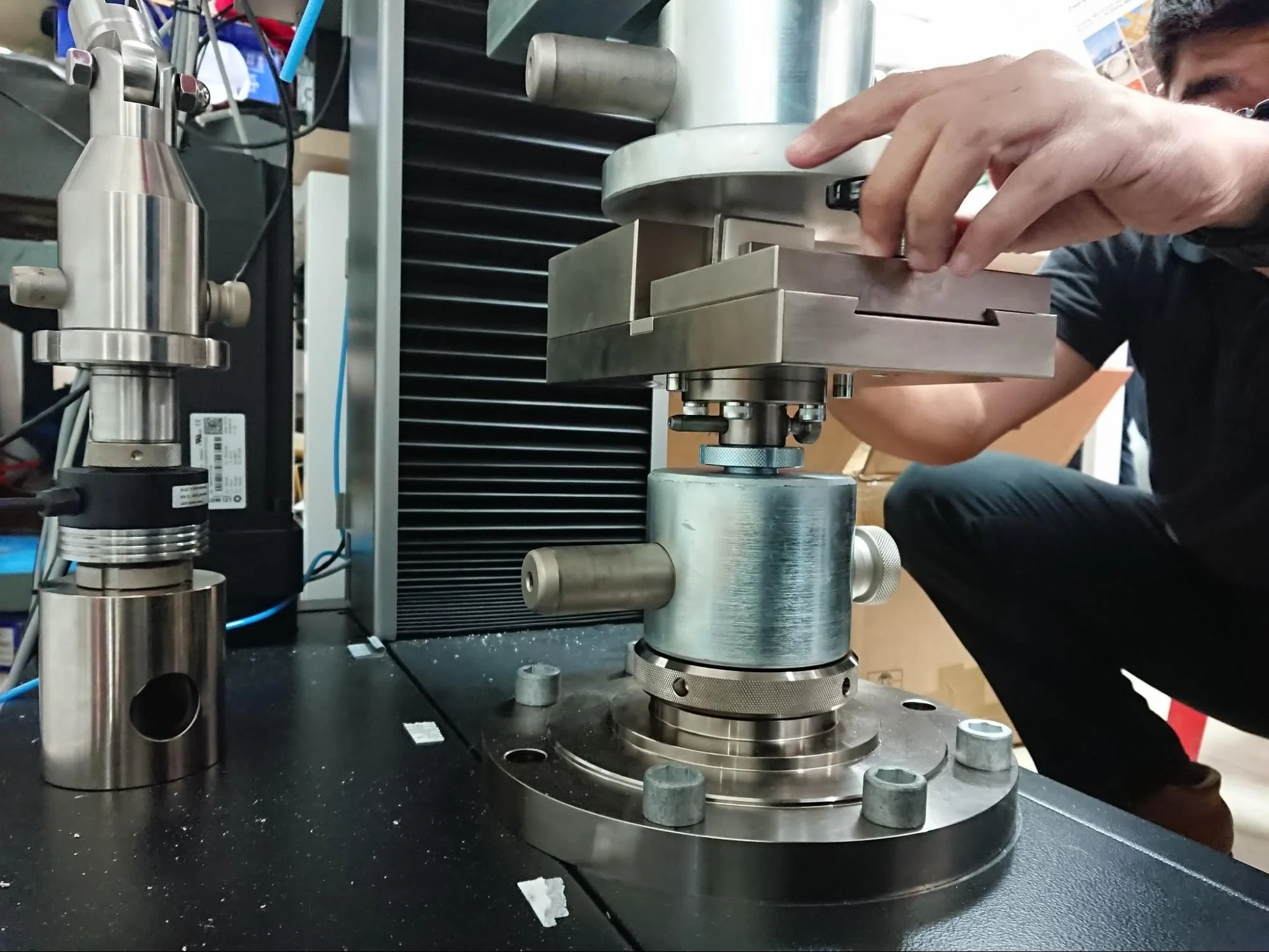

7. Enhanced Quality Control in CNC Machining

Quality is a non-negotiable factor in manufacturing, and CNC manufacturing ensures exceptional reliability through automated quality checks and real-time monitoring.

How CNC Enhances Quality

- In-Process Monitoring: Sensors detect issues like tool wear, reducing the risk of defective parts.

- Post-Production Inspections: Every part undergoes thorough testing to meet client specifications.

At CNCRUSH, we prioritize quality at every step, from CNC manufacturing aluminum parts to CNC millded brass components.

8. Cost-Effective Production for All Scales

The cost savings of CNC machining become more pronounced with larger production volumes. While the upfront costs may be higher, the scalability of CNC systems ensures lower per-unit costs as production increases.

Key Cost Benefits

- Batch Production Efficiency: Unit costs decrease with volume.

- Reduced Tooling Expenses: CNC machining requires fewer tools compared to traditional setups.

CNCRUSH’s expertise in providing affordable CNC machining services ensures you achieve the best ROI, whether you’re producing prototypes or large batches.

9. Cutting-Edge Design Integration

CNC machining’s compatibility with CAD/CAM software bridges the gap between design and manufacturing. Engineers can simulate and optimize production processes before any material is cut, saving time and resources.

Design Integration Advantages

- Fewer Errors: Issues are identified and resolved in the virtual design stage.

- Complex Geometries: CNC manufacturing can produce intricate designs that manual methods cannot achieve.

By choosing CNCRUSH, you benefit from advanced CAD/CAM systems that make your vision a reality.

10. Speed and Consistency: Competitive Differentiators

Speed is a critical advantage of CNC manufacturing. Unlike traditional methods that require significant setup time and manual adjustments, CNC systems are designed for rapid production while maintaining consistent quality.

Why Speed Matters

- Faster Market Entry: Reduced lead times give businesses an edge in competitive markets.

- Consistent Output: High-volume production runs deliver identical parts without variation.

At CNCRUSH, our 12 years of expertise ensure quick turnaround times for CNC Milled parts and CNC Turned parts, helping clients stay ahead.

FAQs About CNC Machining

Q1: What makes CNC manufacturing superior to traditional methods?

A: CNC machining offers superior precision, faster production cycles, and consistent quality. It also supports automation, which reduces labor costs and increases efficiency.

Q2: What industries benefit most from CNC machining?

A: Industries such as automotive, machine building, automation, aerospace, and electronics leverage CNC manufacturing for its precision and scalability.

Q3: Why should I choose CNCRUSH for CNC machining services?

A: CNCRUSH combines over 12 years of experience with cutting-edge technology to provide high-quality CNC manufacturing services for global clients, specializing in both metal and plastic parts.

Conclusion: Empower Your Manufacturing with CNCRUSH

CNC machining has redefined productivity in manufacturing, delivering unparalleled precision, speed, and efficiency. At CNCRUSH, we are committed to providing industry-leading CNC machining services, including CNC Milled parts and CNC Turned parts, tailored to your needs.

Whether you’re in automotive, machine building, or automation, our expertise in custom CNC solutions ensures your success. Visit our website today to learn more and discover why CNCRUSH is your trusted partner for CNC machining in China.