CNC machining is a cornerstone of modern manufacturing, enabling precision and efficiency in creating complex parts across industries like automotive, aerospace, and automation. However, maximizing productivity in CNC machining projects requires strategic adjustments in processes, equipment usage, and workforce management. This comprehensive guide explores ten proven strategies to boost CNC machining productivity, backed by deep insights and professional experience from CNCRUSH, a trusted CNC machining service provider in China with over 12 years of expertise.

Why Productivity Matters in CNC Machining

Productivity in CNC machining directly affects manufacturing costs, lead times, and overall client satisfaction. Efficient machining leads to:

- Reduced cycle times

- Lower material waste

- Consistent part quality

- Faster order completion

At CNCRUSH, we specialize in CNC Milled parts and CNC Turned parts with a focus on efficiency, precision, and cost-effectiveness. If you’re seeking reliable CNC machining services, our team is equipped to handle both prototyping and large-scale production with optimized productivity.

1. Optimize Tool Selection and Maintenance

Choosing the right cutting tools significantly impacts machining speed and quality. High-quality carbide tools or coated inserts can withstand higher speeds and extend tool life.

Key Practices:

- Use material-specific tools for aluminum, steel, and plastics.

- Implement scheduled tool inspections and replacements.

- Invest in tool wear monitoring systems.

Benefit: Extended tool life reduces downtime and scrap rates, increasing throughput in CNC machining projects.

2. Embrace Advanced CNC Programming Techniques

Modern CNC programming methods like trochoidal milling and adaptive clearing can optimize tool paths for faster material removal and reduced tool wear.

Key Practices:

- Use CAM software to simulate tool paths.

- Implement high-speed machining strategies.

- Optimize stepovers and stepdowns.

Benefit: Efficient programming reduces cycle times and enhances part precision in CNC Milled parts and CNC Turned parts.

3. Implement Lean Manufacturing Principles

Lean manufacturing eliminates waste across production processes. In CNC manufacturing, this means reducing idle machine time and optimizing workflow.

Key Practices:

- Apply the 5S method (Sort, Set in order, Shine, Standardize, Sustain).

- Minimize non-value-adding activities.

Benefit: A streamlined workflow leads to faster project completion and lower operational costs.

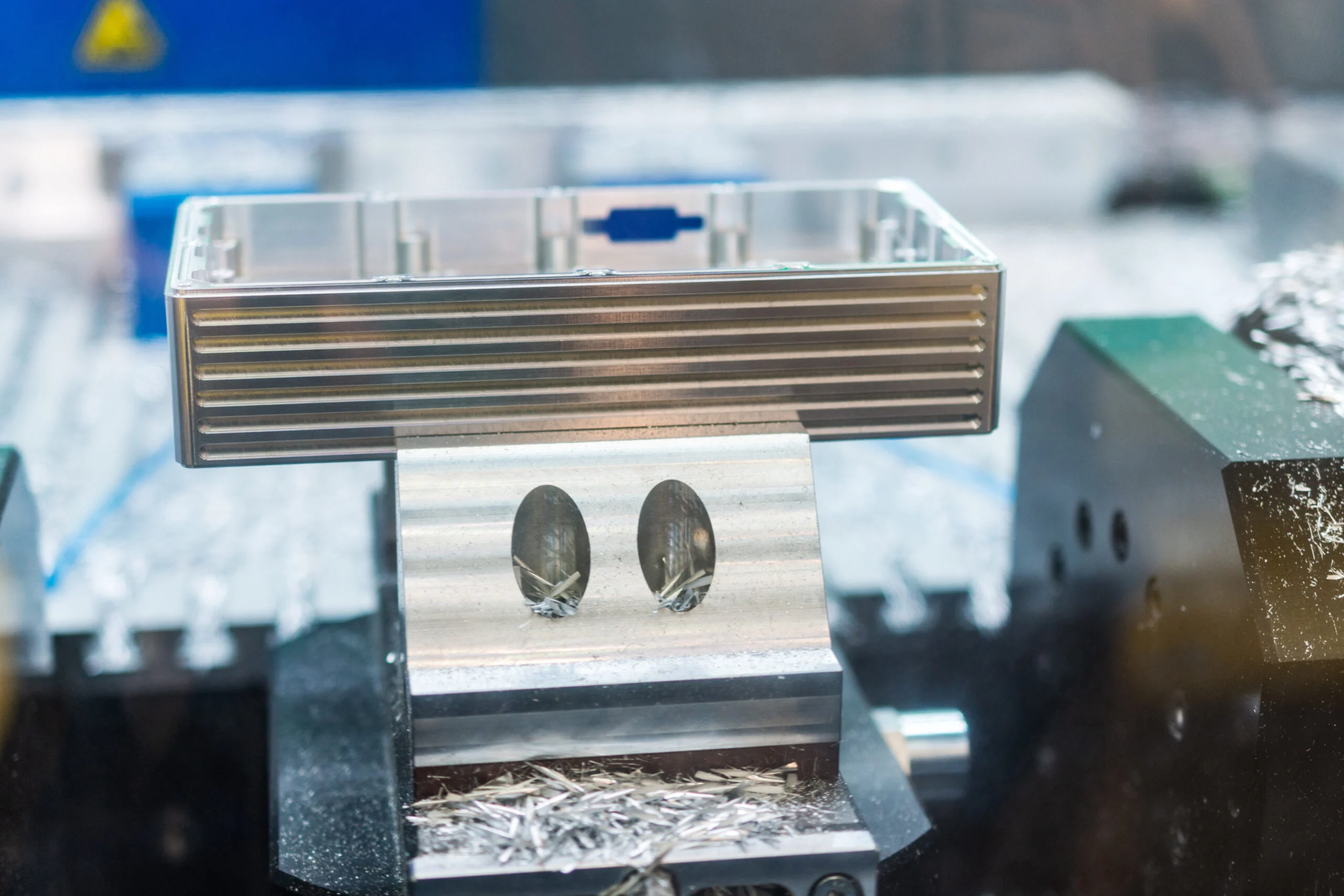

4. Use High-Precision Fixtures and Workholding

Proper workholding ensures part stability, reducing vibrations and improving cutting accuracy.

Key Practices:

- Invest in modular fixtures for flexibility.

- Use zero-point clamping systems.

Benefit: Enhanced part stability results in consistent quality for CNC manufacturing services.

5. Reduce Setup Times with Standardization

Standardizing setups minimizes machine downtime during part changes.

Key Practices:

- Implement quick-change tooling systems.

- Use standard fixture plates for common projects.

Benefit: Faster setups allow for quicker project turnaround, especially in CNC production runs.

6. Train and Upskill CNC Operators

Skilled operators play a crucial role in productivity improvement.

Key Practices:

- Conduct regular CNC programming and tooling workshops.

- Cross-train operators for multiple machines.

Benefit: Competent staff can troubleshoot issues faster and optimize machining strategies.

7. Minimize Material Waste

Material waste not only affects cost but also efficiency.

Key Practices:

- Optimize nesting strategies for sheet machining.

- Use precision cutting strategies for minimal scrap.

Benefit: Reduced material waste lowers production costs for CNC machined components.

8. Automate Repetitive Tasks

Automation can transform productivity in CNC manufacturing services by reducing manual intervention.

Key Practices:

- Implement robotic loading/unloading systems.

- Use bar feeders for CNC lathes.

Benefit: Increased machine uptime and reduced labor costs.

9. Monitor Performance with Real-Time Data

Data-driven insights allow manufacturers to make informed decisions.

Key Practices:

- Use CNC monitoring software for real-time analytics.

- Track cycle times and tool usage patterns.

Benefit: Continuous performance monitoring leads to proactive process improvements.

10. Partner with a Trusted CNC Machining Service

Collaborating with an experienced CNC machining service provider ensures optimized productivity without compromising quality.

At CNCRUSH, our expertise in CNC Milled parts and CNC Turned parts ensures:

- Consistent precision

- Timely deliveries

- Competitive pricing

Contact us today for a consultation and discover how we can streamline your next CNC machining project.

Productivity Comparison: Manual vs. CNC Machining

| Factor | Manual Machining | CNC Machining |

|---|---|---|

| Speed | Slow | High |

| Precision | Moderate | Extremely High |

| Operator Skill Dependency | High | Moderate |

| Setup Time | High | Low with Automation |

| Consistency | Inconsistent | Highly Consistent |

Key Benefits of CNC Machining Services

| Benefit | Impact on Productivity |

| Reduced Cycle Times | Faster Project Completion |

| Lower Tool Wear | Minimized Downtime |

| Automated Workflows | Consistent Output |

| High Accuracy | Fewer Rejections |

FAQ Section

Q: What materials can CNC manufacturing handle? A: CNC machining can handle aluminum, steel, brass, titanium, and plastics with high precision.

Q: How can I ensure consistent quality in CNC parts? A: Use quality inspection tools like CMMs, height gauges, and micrometers, which CNCRUSH employs in every project.

Q: Why choose CNCRUSH for CNC machining services? A: CNCRUSH offers over 12 years of expertise in CNC Milled parts and CNC Turned parts, ensuring precision and reliability.

Conclusion

Maximizing productivity in CNC manufacturing projects requires a combination of advanced tools, optimized programming, and expert service partners. At CNCRUSH, we provide industry-leading CNC machining services with a focus on precision, speed, and cost efficiency. Contact us today to experience unparalleled service excellence for your next CNC project.