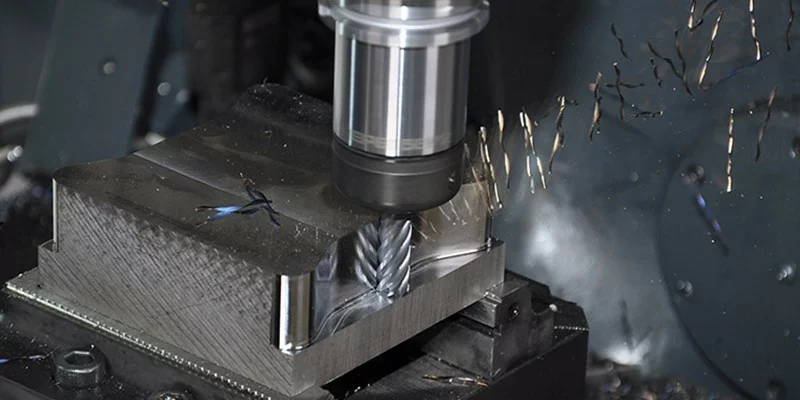

CNC machining for stainless steel parts is a transformative approach in modern manufacturing, providing unmatched precision, durability, and adaptability for various industrial applications. From automotive components to medical instruments, stainless steel’s resilience and the precision offered by CNC machining create a powerful combination. At CNCRUSH, we’ve specialized in delivering high-quality CNC Milled parts and CNC Turned parts for over 12 years, serving industries like automotive, machine building, and automation.

In this article, we will explore the key benefits of CNC machining for stainless steel parts, breaking down its impact on efficiency, cost, and product quality. Stainless steel is a preferred material for critical components due to its corrosion resistance, strength, and ability to maintain tight tolerances in machining processes.

1. The Advantages of CNC Machining for Stainless Steel Parts

CNC machining for stainless steel parts provides numerous advantages that make it a go-to method for industries requiring high precision and durability. These benefits include:

- Corrosion Resistance: Stainless steel’s natural resistance to rust and oxidation ensures long-term performance.

- Strength: CNC machined stainless steel parts are strong, making them ideal for high-stress applications.

- Precision: CNC technology allows for accurate cuts and detailed geometries, maintaining tight tolerances required for critical components.

At CNCRUSH, we use the latest CNC technology to ensure that every part meets your specific needs, whether you require components for automotive, machine building, or automation.

2. Improved Machinability of Stainless Steel Alloys

Different stainless steel grades offer varying degrees of machinability. For example, 304 stainless steel is commonly used for its excellent balance of strength and machinability, while 316 stainless steel is preferred in environments that require additional corrosion resistance.

Key CNC Machining for Stainless Steel Parts grades:

| Stainless Steel Grade | Machinability | Applications |

|---|---|---|

| 303 | Excellent | Gears, fasteners, fittings |

| 304/304L | Good | Medical equipment, valves |

| 316/316L | Moderate | Marine equipment, food processing |

| 17-4PH | Moderate | Aerospace, high-strength parts |

Solution: At CNCRUSH, we choose the right stainless steel grade based on your specific application to ensure optimal performance and durability in your CNC Milled parts or CNC Turned parts.

3. CNC Machining Delivers Precision and Consistency

One of the biggest advantages of CNC machining for stainless steel parts is the precision and repeatability it offers. Whether you’re producing intricate medical devices or robust automotive components, CNC technology ensures consistent quality across every production run.

Benefits of precision CNC machining:

- Tolerances as tight as ±0.001 inches

- High consistency in mass production

- Ability to handle complex geometries with ease

At CNCRUSH, we employ advanced CNC milling and turning machines capable of delivering the tight tolerances required by industries like automotive, machine building, and automation.

4. Superior Surface Finishes and Durability

Stainless steel components machined using CNC technology boast superior surface finishes, ensuring not only aesthetic appeal but also functional advantages like reduced friction and wear. CNC milling and turning ensure the surface finish of stainless steel parts meets the desired specifications.

| Process | Surface Finish Quality | Common Applications |

|---|---|---|

| Milling | Smooth, ideal for visible parts | Automotive components, housings |

| Turning | Ideal for cylindrical parts | Shafts, valves, connectors |

At CNCRUSH, our expertise in CNC Machining for Stainless Steel Parts ensures that every stainless steel component meets the highest standards for both surface finish and durability.

5. Increased Efficiency in High-Volume Production

CNC machining provides unmatched efficiency when it comes to CNC Machining for Stainless Steel Parts at scale. Automated processes allow for the rapid production of complex components, reducing lead times and improving overall production output.

How CNC machining enhances production efficiency:

- Automated workflows reduce human error

- Faster production cycles for high-volume orders

- Cost-effective for both low and high-volume production

At CNCRUSH, we optimize production schedules to meet tight deadlines while maintaining the highest quality standards, making us a trusted partner for automotive, machine building, and automation industries.

6. Cost-Effective Manufacturing of Stainless Steel Parts

While CNC machining for stainless steel parts can involve higher initial costs compared to other materials, the long-term savings in durability, performance, and reduced need for replacements make it a cost-effective solution.

Cost factors in CNC machining for stainless steel:

- Longer tool life due to stainless steel’s durability

- Reduced part failure and replacement costs

- Higher efficiency in large-scale production

Solution: CNCRUSH offers affordable CNC machining services while ensuring that every stainless steel component meets rigorous quality standards, saving you money in the long run.

7. Versatility Across Industries

Stainless steel is used across various industries, from automotive and machine building to aerospace and medical applications. Its versatility, combined with the precision of CNC machining, allows manufacturers to produce parts for virtually any application.

Common applications of CNC Machining for Stainless Steel Parts:

- Automotive: Gears, engine components, fasteners

- Medical: Surgical instruments, implants

- Aerospace: High-strength structural components

At CNCRUSH, we provide custom CNC solutions for industries that demand precision, durability, and reliability in their stainless steel components.

8. Enhanced Material Properties for Specialized Applications

Different grades of CNC Machining for Stainless Steel Parts offer specific material properties that make them ideal for specialized applications. For instance, 316 stainless steel is highly resistant to corrosion, making it suitable for marine or chemical environments, while 17-4PH stainless steel offers high strength and hardness.

Material properties that enhance performance:

- Corrosion resistance: Essential for marine, chemical, and food industries

- High strength: Suitable for heavy-duty applications like construction and automotive

- Heat resistance: Required for high-temperature environments

Solution: At CNCRUSH, we help you select the best stainless steel grade for your project, ensuring optimal performance and longevity in your CNC Milled parts and CNC Turned parts.

9. Sustainability and Long-Term Value

Stainless steel is a sustainable material due to its recyclability and long life span. CNC machined stainless steel parts offer exceptional durability, reducing the need for replacements and minimizing material waste.

Why CNC machining for stainless steel is sustainable:

- 100% recyclable material

- Reduced waste through precise material removal

- Longevity reduces the need for replacements

By choosing CNCRUSH, you’re not only investing in high-quality parts but also in a sustainable manufacturing solution.

10. Why Choose CNCRUSH for CNC Machining for Stainless Steel Parts?

With over 12 years of experience, CNCRUSH is a leading provider of CNC machining services for stainless steel parts. We specialize in both CNC Milled parts and CNC Turned parts, delivering high-precision components tailored to your specific requirements.

Why partner with CNCRUSH:

- Expert in handling stainless steel across industries like automotive, machine building, and automation

- Cutting-edge CNC milling and turning technology

- Competitive pricing and fast turnaround times

- Comprehensive quality control

For high-quality CNC machining services, look no further than CNCRUSH. Contact us today to learn more about our services and how we can help you with your next project.

FAQ

Q1. Why is CNC machining ideal for stainless steel parts?

CNC machining offers precision, consistency, and the ability to work with tough materials like stainless steel, making it ideal for industries that require high-quality, durable parts.

Q2. What stainless steel grades are best suited for CNC machining?

Grades like 303, 304, 316, and 17-4PH are commonly used in CNC machining due to their machinability and material properties, each offering benefits for different applications.

Q3. How does CNC machining improve production efficiency for stainless steel parts?

CNC machining automates the production process, reducing manual labor and ensuring high-volume orders can be fulfilled quickly while maintaining precision.

By leveraging the precision and durability of CNC machining for stainless steel parts, CNCRUSH ensures that your project will be completed to the highest standards.