Selecting the right material is crucial for successful CNC machining projects, especially for precision-focused industries like automotive, aerospace, and automation. This comprehensive guide provides an in-depth look into the best materials for CNC machining—namely, aluminum, steel, and plastics. It explores these materials’ unique properties, applications, and key considerations, helping engineers, designers, and project managers make informed choices. As a seasoned CNC machining service provider with over 12 years of experience, CNCRUSH offers high-quality, precision CNC Milled parts and CNC Turned parts. Our expertise in materials selection ensures exceptional results for each project.

1. Why Aluminum is a Top Choice for CNC Machining Service

Aluminum is favored for its high machinability and cost-effectiveness, especially in the automotive and aerospace sectors. Known for its lightweight and corrosion resistance, aluminum alloys such as 6061 and 7075 provide an exceptional strength-to-weight ratio. Common in CNC Milled parts, aluminum performs well under pressure, making it a preferred material for high-stress components. As a China CNC factory, CNCRUSH specializes in machining aluminum parts with high precision, ensuring quality and durability.

2. Steel Alloys: Durable and Versatile for CNC Turned Parts

Steel offers remarkable strength and durability, especially for CNC Turned parts that require impact resistance. Stainless steel, for example, is corrosion-resistant and is widely used in the medical, marine, and food industries. Alloy steels like 4140 and tool steels such as D2 are ideal for parts subjected to high wear and tear, common in automation and machine-building applications. CNCRUSH’s CNC machining services focus on delivering high-quality steel parts, perfect for industries demanding reliability and longevity.

3. Why Plastics Excel in CNC Machining for High-Precision Needs

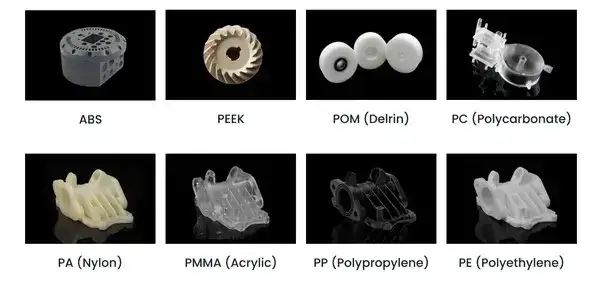

Plastics offer lightweight, corrosion resistance, and electrical insulation, making them ideal for applications in the medical and electronics sectors. CNC plastic materials like ABS, POM (Delrin), and PEEK have high machinability and dimensional stability, essential for CNC Milled parts used in sensitive environments. CNCRUSH’s proficiency with plastics provides flexibility in manufacturing prototypes, particularly in automotive and consumer electronics.

4. Comparing Key Aluminum Grades for CNC Machining Service

Aluminum grades 6061, 6082, and 7075 each bring unique advantages to CNC machining. For example, 6061 is cost-effective and offers good machinability, while 7075, used in aerospace, is stronger but less machinable. Below is a comparison table for better selection:

| Aluminum Grade | Strength | Machinability | Common Applications |

|---|---|---|---|

| 6061 | Medium | Excellent | Automotive parts, general applications |

| 7075 | High | Moderate | Aerospace, high-stress applications |

Understanding the distinctions aids in selecting the right alloy for your specific CNC machining needs.

5. Exploring Stainless Steel and Alloy Steel Grades for High-Quality CNC Milled Parts

Stainless steel grades like 304 and 316 are prized for their corrosion resistance, while 17-4 and duplex stainless steels offer enhanced strength for heavy-duty applications. Alloy steels like 4140 and 4340 are heat-treated to increase wear resistance, making them ideal for industrial equipment.

| Steel Type | Properties | Best for Industries |

|---|---|---|

| Stainless 316 | Corrosion-resistant | Marine, food processing, medical |

| Alloy Steel 4140 | High strength, tough | Machinery, industrial tooling |

| Tool Steel D2 | Very high hardness, durable | Dies, stamps, cutting tools |

These steels allow for specialized applications that demand precision and endurance.

6. Balancing Cost and Performance in CNC Machining with Carbon Steels

Carbon steels are affordable and highly machinable, though they lack the corrosion resistance found in stainless steel. Used primarily in automotive and machine-building, carbon steel grades like 1018 and 1045 balance cost and durability, making them an ideal choice for projects on a tighter budget. CNCRUSH offers CNC machining solutions that prioritize value and performance, providing high-quality carbon steel parts.

7. High-Performance CNC Machining with Magnesium and Titanium Alloys

Magnesium’s lightweight and strength make it optimal for high-temperature applications, such as automotive engine components, while titanium is prized for its biocompatibility and corrosion resistance, ideal for aerospace and biomedical uses. However, both materials require specific handling due to machining challenges, like magnesium’s flammability.

8. Choosing the Best Plastics for Precision CNC Machining in Automotive and Medical Applications

High-performance plastics like PEEK, ABS, and Nylon are commonly used in CNC machining due to their durability, resistance to heat, and machinability. For example, ABS is economical, while PEEK excels in high-temperature conditions, making it suitable for medical implants and high-pressure environments. CNCRUSH’s CNC Milled parts made from plastic are crafted to meet tight tolerances essential in sensitive applications.

9. Machinability and Material Cost: Key Considerations for Optimal CNC Machining

The ease of machining, or “machinability,” is a key factor in CNC material selection, as it affects both time and cost. Aluminum, brass, and acetal are highly machinable, reducing tool wear and improving efficiency. Cost-effective materials like aluminum 6061 and ABS provide a good balance between quality and price. By choosing materials with high machinability, CNCRUSH offers efficient and affordable CNC machining solutions tailored to client needs.

10. Understanding Surface Finishes for CNC Machined Parts

Surface finish options like anodizing for aluminum and passivation for stainless steel enhance both aesthetics and functionality. Plastics can be polished for clarity or textured for grip, while metals can be plated for improved corrosion resistance. CNCRUSH offers a variety of finishing services, allowing clients to achieve the desired look and durability for CNC machined parts.

FAQ: CNC Machining Materials

Q1: Which aluminum alloy is best for lightweight CNC Milled parts?

A1: Aluminum 6061 is a versatile and cost-effective alloy known for its excellent machinability and strength-to-weight ratio, making it ideal for general CNC applications.

Q2: How do I choose between ABS and PEEK for CNC machining?

A2: ABS is economical and offers good impact resistance, while PEEK is more suitable for high-temperature applications requiring chemical resistance and durability.

Q3: Why is steel popular for CNC Turned parts in industrial applications?

A3: Steel alloys provide exceptional strength, wear resistance, and durability, which are essential for parts used in machine building and automation industries.

In conclusion, selecting the best material for CNC machining involves balancing machinability, cost, durability, and specific application requirements. CNCRUSH is dedicated to helping clients choose the optimal material, ensuring high-quality CNC Milled parts and CNC Turned parts for diverse industries such as automotive, medical, and aerospace. Our precision-driven approach and extensive experience set us apart, providing unmatched value and expertise to each project. Explore CNCRUSH’s CNC machining services for your next high-quality production solution.