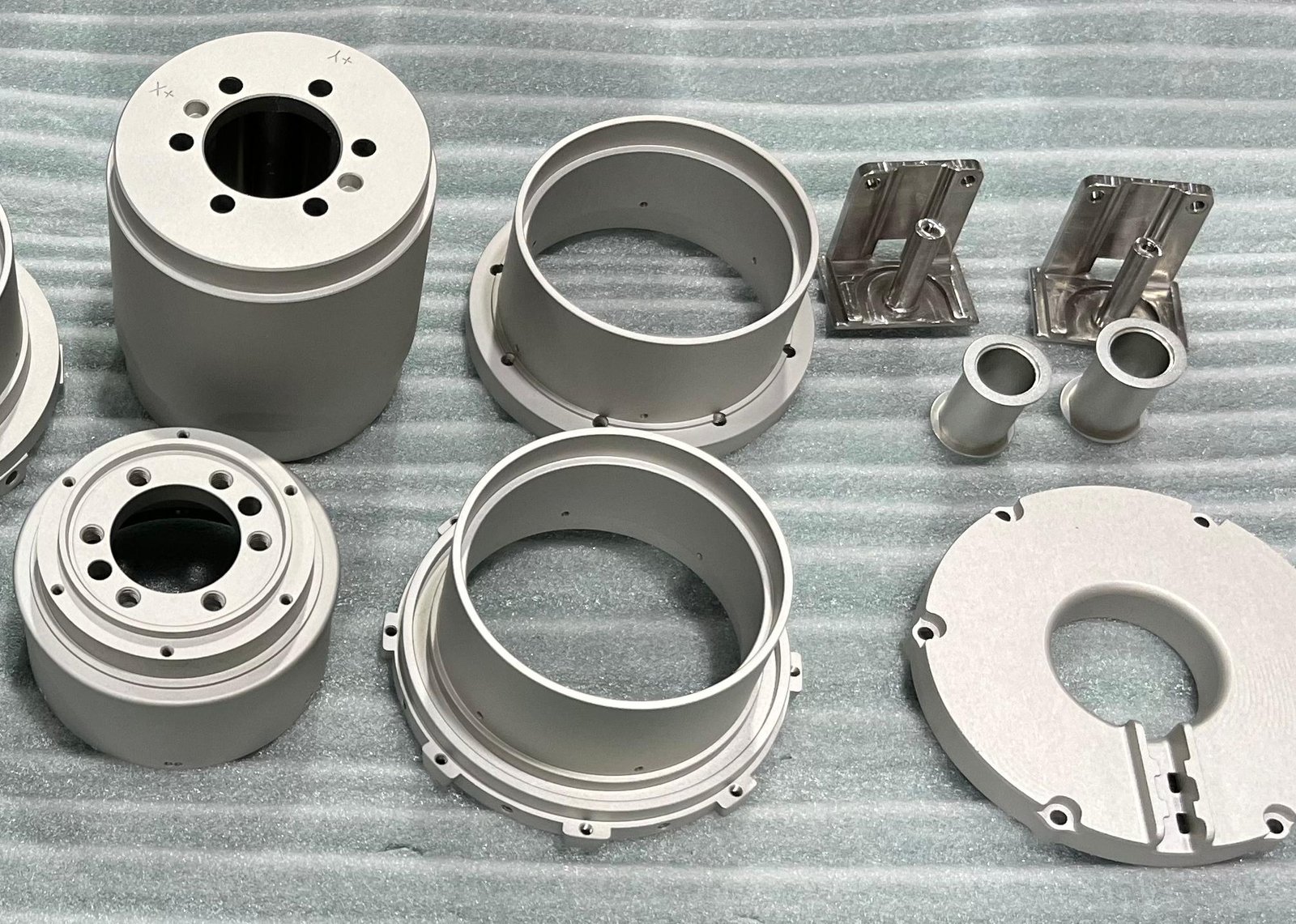

CNC Machining is a cornerstone of modern aerospace manufacturing, enabling the production of high-precision components essential for aircraft performance and safety. The selection of appropriate materials is critical, as aerospace parts must withstand extreme conditions while maintaining structural integrity.

This article delves into the top materials used in CNC machining for the aerospace industry, providing an in-depth analysis of their properties, applications, and advantages.

1. Titanium Alloys in CNC Machining

Titanium alloys are renowned for their exceptional strength-to-weight ratio and corrosion resistance, making them ideal for aerospace applications. These materials maintain structural integrity under extreme temperatures and are commonly used in engine components, airframes, and landing gear.

2. Aluminum Alloys: Versatility in Aerospace Components

Aluminum alloys are lightweight and possess excellent machinability, making them a staple in aerospace manufacturing. They are used in various components, including fuselage frames and wing structures, due to their high strength-to-weight ratio and resistance to corrosion.

3. Nickel-Based Superalloys: High-Temperature Performance

Nickel-based superalloys, such as Inconel, are designed to withstand extreme temperatures and mechanical stress. They are essential in the production of turbine blades and other engine parts that operate under high thermal conditions.

4. Stainless Steel: Durability and Corrosion Resistance

Stainless steel offers a balance between strength, corrosion resistance, and machinability. It is utilized in various aerospace components, including fasteners and structural parts, where durability is paramount.

5. Composites: Advanced Materials for Modern Aircraft

Composite materials, such as carbon fiber-reinforced polymers, provide high strength and stiffness while being lightweight. They are increasingly used in aerospace for components like fuselage sections and control surfaces to enhance fuel efficiency and performance.

6. Magnesium Alloys: Lightweight Solutions

Magnesium alloys are among the lightest structural metals, offering significant weight savings. They are used in non-critical aerospace components where reducing weight is essential without compromising strength.

7. Copper Alloys: Electrical and Thermal Conductivity

Copper alloys are employed in aerospace applications requiring excellent electrical and thermal conductivity. They are used in components like electrical connectors and heat exchangers.

8. High-Performance Plastics: Specialized Applications

High-performance plastics, such as PEEK and PTFE, are used in aerospace for components requiring chemical resistance, lightweight, and thermal stability. They are often found in seals, insulators, and interior components.

9. Refractory Metals: Extreme Environment Applications

Refractory metals like tungsten and molybdenum are used in aerospace applications that involve extreme temperatures and require materials with high melting points and strength.

10. Advanced Ceramics: Cutting-Edge Aerospace Materials

Advanced ceramics are utilized in aerospace for components that require high-temperature resistance, wear resistance, and electrical insulation properties.

Selecting the appropriate material for CNC machining in the aerospace industry is crucial for ensuring component performance, safety, and longevity. Each material offers unique properties that cater to specific applications within the aerospace sector.

For professional CNC machining services specializing in aerospace components, CNCRUSH offers over 12 years of experience in delivering high-quality CNC milled and turned parts. Our expertise ensures that each component meets the stringent standards required in the aerospace industry.

Contact CNCRUSH for Your Aerospace CNC Machining Needs

With a commitment to precision and quality, CNCRUSH is your trusted partner for CNC machining services in the aerospace industry. Our state-of-the-art facilities and experienced team are dedicated to delivering components that meet your exact specifications.

Frequently Asked Questions (FAQ)

Q1: What factors should be considered when selecting materials for CNC machining in the aerospace industry?

A1: Key factors include strength-to-weight ratio, temperature resistance, corrosion resistance, machinability, and the specific application requirements of the component.

Q2: Why is titanium commonly used in aerospace CNC machining?

A2: Titanium offers an excellent strength-to-weight ratio and high corrosion resistance, making it suitable for critical aerospace components that must withstand extreme conditions.

Q3: How does CNCRUSH ensure the quality of CNC machined aerospace parts?

A3: CNCRUSH utilizes advanced CNC machining technology, adheres to strict quality control processes, and employs experienced professionals to ensure each part meets industry standards and client specifications.

Q4: Can CNCRUSH handle complex aerospace component designs?

A4: Yes, CNCRUSH specializes in producing complex and precise CNC milled and turned parts, catering to the intricate designs often required in the aerospace industry.

Q5: What is the typical turnaround time for CNC machined parts at CNCRUSH?

A5: Turnaround times vary depending on the complexity and quantity of the parts. CNCRUSH is committed to delivering high-quality components within agreed timelines and offers expedited services when necessary.

For more information or to request a quote, visit our website at CNCRUSH.