CNC Machining is transforming the automotive industry with greater precision, adaptability, and sustainability. Discover 10 powerful trends reshaping CNC machining for automotive manufacturing in 2025 and beyond.

CNC-bewerking is at the forefront of innovation in the automotive industry. As vehicles become smarter, more complex, and environmentally conscious, the demand for precise, scalable, and efficient manufacturing methods is increasing. Based on insights from leading industry reports and expert analyses, this in-depth guide explores the ten key trends shaping the future of CNC machining in the automotive sector, with a strong emphasis on how companies like CNCRUSH, een leidende CNC machining service provider in China with over 12 years of experience, are positioning themselves at the center of this transformation.

🔧 1. CNC Machining and the Automotive Industry: A Perfect Match

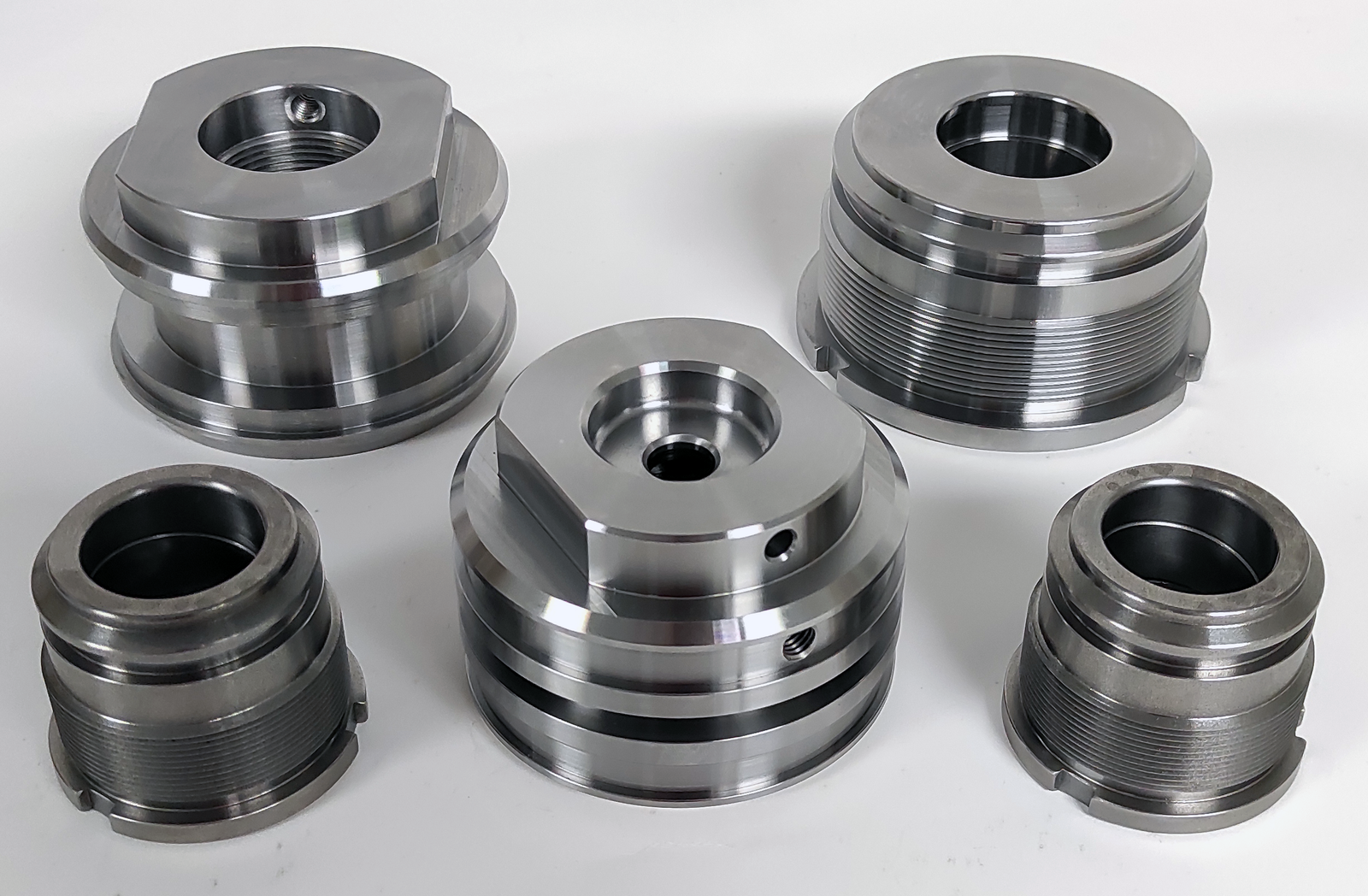

CNC-bewerking aligns perfectly with the automotive sector’s rigorous demands for precision, repeatability, and speed. From CNC-gefreesde onderdelen in gearboxes to CNC-gedraaide onderdelen for drive shafts, CNC machining plays a vital role in delivering components that meet exact tolerances every time.

Why this matters:

Modern automotive systems—from hybrid drivetrains to ADAS (advanced driver assistance systems)—require components that are microns-accurate. Manual methods simply can’t match the consistency offered by computer-controlled processes.

Positive Sentiment Word: Reliable

CNC machining offers reliable precision that ensures vehicle safety and performance.

2. Opkomst van lichtgewicht componenten en de rol van CNC

One of the biggest shifts in automotive is the drive for lightweighting to improve fuel efficiency and EV range. CNC machining enables the use of aluminum, magnesium, and carbon-fiber composites, processed to the highest dimensional accuracy.

Belangrijkste inzicht:

Lightweight components still need to withstand high mechanical stress. CNC machining ensures strength is not sacrificed for weight.

Bij CNCRUSH, we regularly produce CNC-gefreesde onderdelen from high-strength aluminum alloys for clients in the automobiel En machinebouw industries. Our precision ensures lightweight doesn’t mean fragile.

⚙️ 3. Integration with AI and Smart Manufacturing

The next generation of CNC machines is being equipped with AI-driven predictive maintenance, real-time optimization, and autonomous correction algorithms.

What this means for automotive production:

-

Downtime is minimized

-

Tolerances are maintained more tightly

-

Productivity scales more easily

AI in CNC machining allows for more efficient handling of large production volumes, especially in EV motor housing and transmission assemblies.

Sentiment Word: Game-changing

AI-enhanced CNC machining is a game-changing advancement for automotive manufacturers seeking efficiency and agility.

🧠 4. CNC Machining Meets Industry 4.0

Industry 4.0 isn’t just a buzzword—it’s redefining the automotive CNC machining workflow. Smart factories are integrating:

-

Real-time data monitoring

-

IoT-connected CNC equipment

-

Seamless ERP/MRP integrations

These innovations allow factories like CNCRUSH to manage traceability, part validation, and machining tolerances with real-time updates, which is essential for automotive compliance.

🌍 5. Sustainability in CNC Machining for Automotive

The automotive industry is under pressure to reduce its carbon footprint. CNC manufacturing contributes to sustainability through:

-

Material optimization (less waste from subtractive processes)

-

Recyclable metals (aluminum, steel)

-

Energy-efficient CNC manufacturing

Bij CNCRUSH, ons CNC-productiediensten are powered by optimized toolpaths and efficient processes that reduce material waste by up to 30%.

Table 1: Comparison – Traditional vs. Sustainable CNC Machining

| Functie | Traditionele bewerking | Sustainable CNC (CNCRUSH) |

|---|---|---|

| Materieel afval | Hoog | Laag |

| Energie-efficiëntie | Gematigd | Hoog |

| Recyclability Focus | Laag | Hoog |

| Emissions per Part | Hoog | Verminderd |

🚗 6. Customization and Prototyping for Automotive Innovation

With the rise of custom EVs, concept cars, and low-volume production runs, CNC manufacturing is key for snelle prototypering En short-run manufacturing.

Why CNC is ideal for this:

-

Fast setup

-

No tooling required

-

Tight tolerances on first runs

CNCRUSH's CNC-bewerkingsdiensten allow automotive clients to go from CAD model to prototype in days. Whether it’s CNC-gefreesde onderdelen for dashboard interfaces or CNC-gedraaide onderdelen for custom suspension systems, we support clients at every stage of development.

🔁 7. CNC Machining and Supply Chain Resilience

Post-pandemic supply chains have revealed the need for flexibility. CNC manufacturing allows for on-demand manufacturing, reducing reliance on large inventories and long logistics cycles.

This capability is vital for:

-

OEMs adapting to fluctuating EV demand

-

Tier-2 suppliers adjusting production

-

Niche vehicle builders needing just-in-time parts

CNCRUSH has been a stable CNC partner for companies in automotive, automation, and machine building, helping them navigate volatility with high responsiveness.

🤖 8. Multi-Axis CNC Machining and Complex Geometries

Advanced automotive parts require machining on multiple surfaces and axes. 5-assige CNC-machines allow for:

-

Minder opstellingen

-

Complexe geometrieën

-

Enhanced accuracy

Use case:

Turbocharger impellers, EV battery enclosures, and gearbox housings all benefit from multi-axis CNC machining.

CNCRUSH is equipped with 5-axis, 4-axis, and 3-axis machines to handle any automobiel geometry, delivering optimized CNC-gefreesde onderdelen at scale.

Table 2: Axis Capability Comparison

| Axis Type | Setup Reduction | HTTPError: Response code 429 (Too Many Requests) | Precisieniveau |

|---|---|---|---|

| 3-assig | HTTPError: Response code 429 (Too Many Requests) | Simple | Hoog |

| 4-assig | Gematigd | Medium | Zeer hoog |

| 5-assig | Hoog | Complex | Ultra High |

🛠 9. CNC Machining for Electric Vehicles (EVs)

Electric vehicles are accelerating CNC manufacturing demand for:

-

Battery pack frames

-

Motor housings

-

Cooling components

-

Mounting brackets

Why CNC manufacturing fits EVs:

-

Parts are non-standard and evolving

-

Prototypes are frequently required

-

Heat management is crucial, requiring high-tolerance fits

CNCRUSH specializes in precision CNC-gedraaide onderdelen En CNC-gefreesde onderdelen for the emerging EV segment, working with global clients to deliver scalable machining solutions.

📈 10. Globalization and China’s Role in CNC Machining

China remains a dominant force in automotive CNC manufacturing. Companies like CNCRUSH, with 12+ years of CNC expertise, provide world-class machining with competitive pricing.

Why choose CNCRUSH:

-

Full-service CNC-bewerkingsservice in aluminum, steel, and plastic

-

Expertise in automobiel, machinebouw, En automatisering

-

Full quality control including CMM, micrometers, and height gauges

Of je nu een internationale OEM bent of een lokale startup, CNCRUSH helpt je om efficiënt te schalen met betrouwbare CNC-productiediensten.

❓ FAQ: CNC Machining for the Automotive Industry

Q1: What are the most commonly machined parts in the automotive sector?

A1: Engine components, transmission housings, suspension arms, and electric vehicle modules.

Q2: Why is CNC manufacturing preferred over injection molding for automotive prototyping?

A2: CNC manufacturing allows for faster turnaround, no molds, and high material flexibility.

Q3: Can CNCRUSH handle small-volume CNC machining orders?

A3: Absolutely. We support both prototype and mass production.

Q4: What materials does CNCRUSH work with for automotive parts?

A4: Aluminum, stainless steel, carbon steel, engineering plastics, and titanium alloys.

🌟 Conclusion: CNC Machining is Driving the Future of Automotive

CNC-productie is niet langer alleen een ondersteunend proces - het is een strategische motor voor innovatie in de auto-industrie. From electric vehicles to smart manufacturing and sustainability, the CNC landscape is evolving rapidly. Companies that embrace precision, speed, and adaptability will lead the pack.

CNCRUSH, as a trusted CNC machining service provider based in China, is proud to support global automotive leaders with premium CNC-gefreesde onderdelen En CNC-gedraaide onderdelen. With over 12 years of experience, state-of-the-art equipment, and dedicated customer support, we invite you to contact us for your next automotive CNC project.

🔧 Reach out to CNCRUSH today for professional CNC machining service that drives your automotive innovation forward.