CNC Cutting is the foundation of precision valve seat manufacturing, directly determining sealing performance, combustion efficiency, and long-term engine reliability across automotive, machine building and automotion industries.

Executive Summary: What Industry Leaders Reveal About Valve Seat CNC Cutting

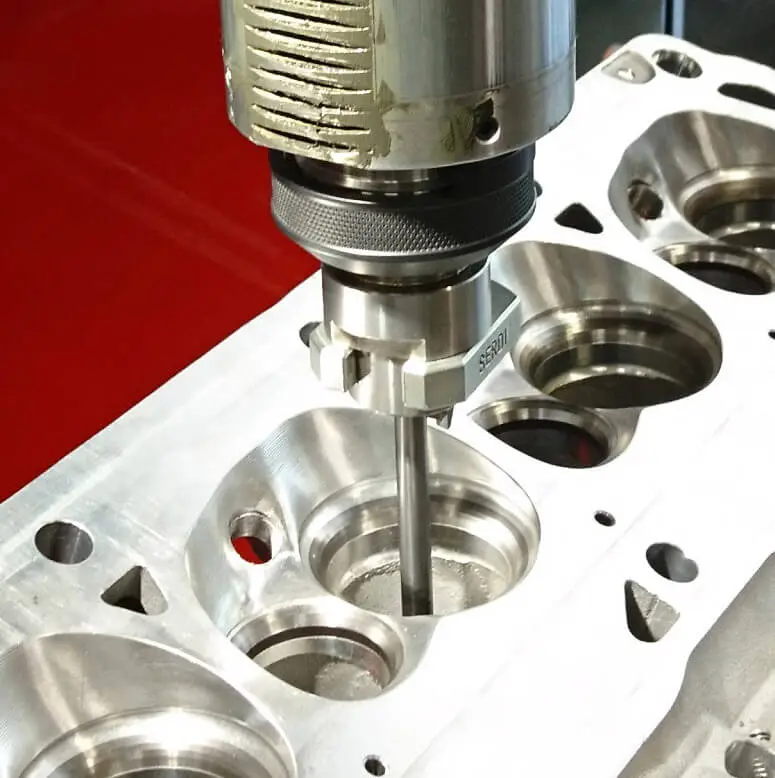

Across the global valve seat machining industry, leading manufacturers emphasize one core truth: precision CNC Cutting of valve seats is no longer optional—it is mission-critical. Advanced multi-axis CNC machines, rigid tooling strategies, micron-level tolerances, and data-driven process control define today’s competitive edge.

The common thread behind industry leaders is not just specialized equipment, but deep CNC machining know-how, disciplined process engineering, and the ability to consistently deliver repeatable accuracy at scale. This article distills those insights and expands them with practical manufacturing analysis, while showing how CNCRUSH, a China-based factory with over 12 years of CNC machining service experience, applies these principles to deliver high-precision CNC Milled parts and CNC Turned parts for global clients.

1. CNC Cutting and the Critical Role of Valve Seats in Engine Performance

Valve seats are small components with enormous responsibility. From a mechanical standpoint, CNC Cutting defines:

-

Valve-to-seat sealing efficiency

-

Heat transfer from valve to cylinder head

-

Combustion pressure containment

-

Wear resistance under extreme cyclic loads

Even a microscopic deviation caused by improper CNC Cutting can result in compression loss, premature wear, and costly engine failure—a negative outcome no OEM or engine rebuilder can accept.

In modern automotive and machine building environments, valve seats must withstand higher RPMs, increased combustion pressures, and aggressive fuel profiles. This reality places CNC Cutting accuracy at the center of component performance.

2. CNC Cutting and Material Challenges in CNC Machining Service for Valve Seats

Valve seats are typically produced from:

-

Alloy steels

-

Powdered metal composites

-

Hardened inserts

-

High-nickel or cobalt-based alloys

Each material introduces distinct machining resistance, heat generation, and tool wear patterns. A professional CNC machining service must adapt CNC Cutting parameters—feeds, speeds, tool geometry, and coolant strategies—to each material’s behavior.

At CNCRUSH, our 12 years of experience allow us to precisely tune CNC Milled parts and CNC Turned parts strategies for these demanding materials, ensuring dimensional stability even during high-volume production.

3. CNC Cutting Accuracy Requirements in CNC Milled Parts and CNC Turned Parts

Valve seat machining demands tolerances that often fall within micron-level accuracy. CNC Cutting must control:

-

Seat concentricity

-

Roundness

-

Surface finish

-

Contact angle geometry

These requirements often require a hybrid approach using both CNC Milled parts and CNC Turned parts processes. CNC turning ensures concentric geometry, while CNC milling refines angles and surface transitions.

Failure to coordinate these processes introduces cumulative error—a silent killer in valve seat performance.

4. CNC Cutting Process Stability in Automotive and Automotion Production

In automotive, machine building and automotion industries, consistency is more valuable than theoretical peak accuracy. CNC Cutting must remain stable across:

-

Long production runs

-

Multiple machine shifts

-

Tool change cycles

-

Batch-to-batch material variation

A negative sentiment often shared by OEM buyers is frustration with suppliers who deliver perfect first samples—but fail to maintain consistency in mass production.

CNCRUSH addresses this by integrating process documentation, tool-life monitoring, and statistical process control into every CNC machining service program.

5. CNC Cutting Tooling Strategy in CNC Machining Service

Tooling defines CNC Cutting success more than machine brand alone. Valve seat cutting tools must offer:

-

High rigidity

-

Vibration suppression

-

Precise edge geometry

-

Predictable wear patterns

Advanced CNC machining service providers select tooling not for speed alone, but for process reliability and surface integrity.

For CNC Milled parts, multi-point cutters optimize surface blending, while CNC Turned parts rely on ultra-stable inserts to maintain roundness under thermal load.

6. CNC Cutting Surface Finish and Sealing Efficiency

Surface finish directly affects valve sealing and heat transfer. Poor CNC Cutting parameters create micro-tears that accelerate wear and carbon buildup—a negative performance spiral.

High-quality CNC machining service focuses on:

-

Controlled chip evacuation

-

Minimal tool chatter

-

Optimized feed per tooth

-

Balanced spindle loads

At CNCRUSH, surface integrity is treated as a functional requirement, not merely an aesthetic one—especially for automotive and automotion components.

7. CNC Cutting Automation and Repeatability in CNC Milled Parts

Modern valve seat production increasingly relies on automated CNC Cutting cycles. Automation improves:

-

Repeatability

-

Throughput

-

Operator independence

However, automation amplifies mistakes. Without a robust CNC machining service foundation, errors replicate faster than they can be corrected.

This is why CNCRUSH emphasizes process validation before automation, ensuring CNC Milled parts meet specification before scaling output.

8. CNC Cutting Quality Control for CNC Turned Parts

Quality control closes the loop in CNC Cutting. Effective inspection strategies include:

-

In-process probing

-

Air gauging

-

Optical measurement

-

Post-process CMM validation

For CNC Turned parts like valve seat inserts, concentricity and roundness are non-negotiable. CNCRUSH integrates inspection checkpoints directly into the machining workflow, preventing deviation before it becomes costly scrap.

9. CNC Cutting Cost Optimization Without Performance Loss

A common negative assumption is that high-precision CNC Cutting is always expensive. In reality, poor machining is far more costly over time.

Optimized CNC machining service balances:

-

Tool life vs. cutting speed

-

Setup time vs. batch size

-

Scrap rate vs. inspection frequency

By engineering the process rather than chasing speed alone, CNCRUSH helps clients reduce total cost while improving component reliability.

10. CNC Cutting and Why CNCRUSH Is a Trusted CNC Machining Service Partner

CNCRUSH is a China-based CNC machining service provider with over 12 years of manufacturing experience, serving global customers across automotive, machine building and automotion sectors.

We specialize in:

-

High-precision CNC Milled parts

-

Tight-tolerance CNC Turned parts

-

Small to medium batch production

-

Scalable long-term manufacturing programs

Our strength lies not only in machines, but in engineering judgment, disciplined CNC Cutting strategies, and long-term customer trust.

Comparative Analysis Table: CNC Cutting Factors Affecting Valve Seat Quality

| CNC Cutting Factor | Impact on Performance | Risk if Poorly Controlled |

|---|---|---|

| Concentricity | Valve sealing efficiency | Compression loss |

| Surface Finish | Heat transfer & wear | Premature failure |

| Tool Stability | Dimensional accuracy | Chatter & scrap |

| Process Consistency | Production reliability | Batch variation |

CNC Milled Parts vs CNC Turned Parts in Valve Seat Manufacturing

| Aspect | CNC Milled Parts | CNC Turned Parts |

|---|---|---|

| Geometry Control | Complex angles | Roundness & symmetry |

| Typical Use | Seat angles, transitions | Inserts, circular profiles |

| CNC Cutting Focus | Multi-axis accuracy | Spindle stability |

| Risk Area | Tool deflection | Thermal growth |

FAQ: CNC Machining for Valve Seat Machining

Q1: Why is CNC Machining so critical for valve seats?

Because valve seats directly affect sealing, combustion efficiency, and engine lifespan.

Q2: Can one CNC process handle all valve seat features?

No. High-quality production often combines CNC Milled parts and CNC Turned parts.

Q3: How does material selection affect CNC Machining?

Different alloys change tool wear, heat generation, and surface finish behavior.

Q4: Is CNC Machining suitable for small batch production?

Yes. With the right CNC machining service, small batches can achieve the same precision as mass production.

Q5: Why choose a China-based CNC machining service like CNCRUSH?

Because CNCRUSH combines cost efficiency with 12 years of proven precision machining experience and global quality standards.

Final Thoughts: CNC Machining as a Competitive Advantage

Precision CNC Cutting is no longer just a manufacturing step—it is a strategic advantage. Companies that invest in professional CNC machining service partners gain better product reliability, lower lifecycle costs, and stronger customer trust.

If you are looking for a dependable partner for CNC Milled parts and CNC Turned parts, CNCRUSH stands ready to support your automotive, machine building and automotion projects with precision, consistency, and confidence.