CNC Manufacturing has become the backbone of industries like automotive, machine building, and automation, providing precision, reliability, and scalability. Selecting the right CNC machine for your manufacturing project is a critical decision that can directly impact efficiency and cost-effectiveness. At CNCRUSH, a trusted China-based CNC factory with over 12 years of expertise in CNC manufacturing services, we specialize in producing CNC Milled parts and CNC Turned parts that meet stringent global standards.

This guide explores the nuances of choosing the best CNC machine while highlighting how our professional services at CNCRUSH can enhance your projects. By diving deep into key considerations, providing actionable insights, and answering common questions, this article ensures your success in CNC manufacturing.

Contents

- Understanding CNC Machines: A Beginner’s Guide

- Determining Your Manufacturing Needs

- Types of CNC Machines and Their Uses

- Key Features to Look for in a CNC Machine

- Choosing the Right CNC Materials

- CNC Software and Programming: Why It Matters

- Costs and ROI: Making an Informed Investment

- Common Pitfalls in Selecting CNC Machines

- How CNCRUSH Can Help Your CNC Projects

- FAQs About CNC Machine Selection

Understanding CNC Machines: A Beginner’s Guide

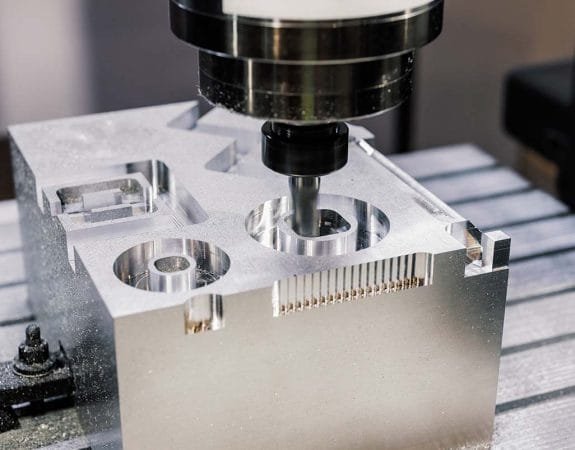

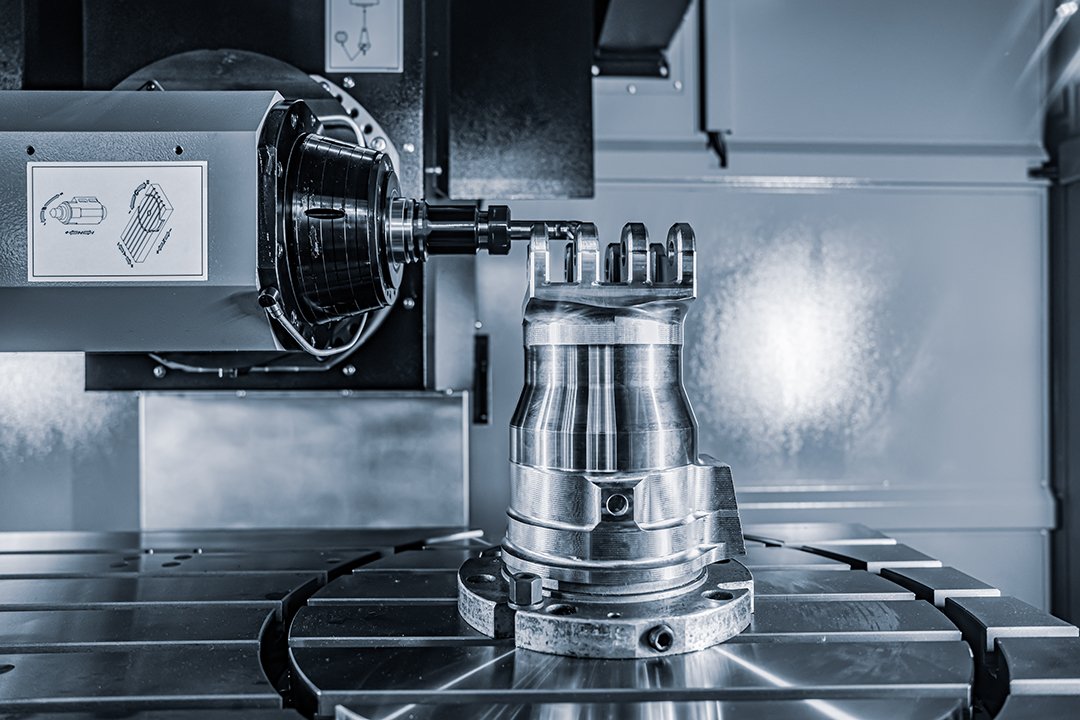

CNC (Computer Numerical Control) machines automate the manufacturing process by precisely controlling tools to produce complex parts. These machines are integral in industries like automotive, machine building, and automation. They include options like CNC mills, CNC lathes, and multi-axis machines for different production needs.

Key Insight:

Choosing the right CNC machine starts with understanding how CNC manufacturing aligns with your production goals, whether it’s prototyping, mass production, or custom parts manufacturing.

Determining Your Manufacturing Needs

Before selecting a CNC machine, assess your requirements:

- Volume: Are you producing small batches or large-scale orders?

- Material: Consider materials like aluminum, steel, or plastics.

- Precision Requirements: Industries like aerospace and medical require high-tolerance machining.

- Production Speed: Match the machine’s speed with your project timeline.

Table: Matching CNC Machines to Industry Needs

| Industry | Material | Recommended Machine |

|---|---|---|

| Automotive | Steel, Aluminum | CNC Lathes, CNC Mills |

| Medical Equipment | Titanium, Plastics | 5-Axis CNC Machines |

| Electronics | Plastics, Copper | CNC Milling Machines |

| Aerospace | Composites, Metals | Multi-Axis CNC Machines |

Types of CNC Machines and Their Uses

CNC machines vary based on their functionality and purpose:

- CNC Mills: Ideal for cutting intricate parts from metal or plastic.

- CNC Lathes: Used for creating cylindrical parts like shafts and gears.

- Multi-Axis Machines: Combine milling and turning, perfect for complex geometries.

Did You Know?

At CNCRUSH, we specialize in producing CNC Milled parts and CNC Turned parts, ensuring optimal solutions for diverse manufacturing needs.

Key Features to Look for in a CNC Machine

When evaluating a CNC machine, focus on:

- Accuracy: Tolerance levels as low as ±0.01mm for precision industries.

- Durability: Machines with robust frames for long-term reliability.

- Speed: Check spindle speed and feed rates for high productivity.

- Automation Features: Look for advanced CNC programming capabilities.

Insight:

High-quality CNC manufacturing services depend on machines with superior performance, which is why CNCRUSH invests in cutting-edge technology.

Choosing the Right CNC Materials

Material compatibility is crucial when choosing a CNC machine. Common materials include:

- Aluminum: Lightweight, versatile, and used in automotive and aerospace industries.

- Steel: Preferred for heavy-duty applications.

- Plastics: Essential for electronic components and medical devices.

Pro Tip:

Collaborate with experts like CNCRUSH to match the machine with your material needs, ensuring quality and cost-efficiency.

CNC Software and Programming: Why It Matters

The efficiency of CNC manufacturing depends on programming:

- CAD/CAM Software: Converts designs into machine-readable formats.

- Compatibility: Ensure the machine supports your preferred software.

Table: Leading CNC Software Options

| Software | Key Features | Compatibility |

|---|---|---|

| Mastercam | Advanced toolpath creation | CNC Mills, CNC Lathes |

| Fusion 360 | Cloud-based design & machining | Multi-Axis CNC Machines |

| Siemens NX | Comprehensive simulation tools | High-end CNC Machines |

Costs and ROI: Making an Informed Investment

A CNC machine is a significant investment. Calculate costs by considering:

- Machine Price: Initial investment and financing options.

- Operational Costs: Maintenance, energy, and labor.

- ROI: Improved efficiency often leads to long-term savings.

Tip:

CNCRUSH offers affordable CNC manufacturing services, allowing businesses to reduce upfront costs while achieving precision results.

Common Pitfalls in Selecting CNC Machines

Avoid these mistakes when choosing your CNC machine:

- Ignoring Scalability: Opt for a machine that meets future production demands.

- Underestimating Training Needs: Ensure staff can operate advanced machines.

- Overlooking Material Versatility: Machines should handle a range of materials.

Action Step:

Consult professionals like CNCRUSH to ensure your CNC machine meets your project goals without unnecessary compromises.

How CNCRUSH Can Help Your CNC Projects

As a leading CNC factory in China, CNCRUSH specializes in high-quality, affordable CNC manufacturing services. Our advantages include:

- Expertise: 12 years of experience producing CNC Milled parts and CNC Turned parts.

- Global Reach: Trusted by clients in industries like automotive, machine building, and automation.

- Versatility: Proficiency in materials like aluminum, steel, and plastics.

Call to Action:

Visit CNCRUSH to explore our custom CNC solutions and experience unmatched precision and reliability.

FAQs About CNC Machine Selection

Q1: What’s the best CNC machine for small businesses?

A: Consider versatile and cost-effective machines like 3-axis CNC mills for general purposes.

Q2: How do I determine CNC compatibility with my materials?

A: Check the machine’s spindle power, tooling options, and software capabilities.

Q3: Why choose CNCRUSH for CNC manufacturing services?

A: CNCRUSH delivers precision parts at competitive prices, with 12 years of proven expertise.

Q4: How long does CNC programming take?

A: It depends on the complexity of the design and operator expertise; basic setups can take hours, while advanced designs may take days.

Q5: Can CNCRUSH handle custom prototypes?

A: Absolutely. We specialize in CNC prototype machining tailored to specific requirements.

By choosing the right CNC machine and partnering with reliable experts like CNCRUSH, your manufacturing projects are set for success. Whether you need CNC Milled parts, CNC Turned parts, or custom solutions, we’re here to help you achieve excellence in CNC manufacturing. Visit CNCRUSH today for a consultation.