CNC Turning is crucial for manufacturing high-precision flywheels. Discover expert strategies, CNC machining techniques, and how CNCRUSH delivers superior CNC Milled parts and CNC Turned parts for automotive, machine building, and automation applications.

Introduction

CNC Turning is a cornerstone of precision manufacturing, particularly for critical components such as flywheels. These essential parts store and transfer rotational energy in engines, requiring extreme dimensional accuracy, balance, and surface finish. High-precision CNC Turning ensures that flywheels meet stringent performance and safety standards. Drawing insights from leading industry practices, this article explores nine essential strategies for achieving superior flywheel performance using CNC Turning. CNCRUSH, with over 12 years of CNC machining service experience, specializes in CNC Milled parts and CNC Turned parts for automotive, machine building, and automation industries.

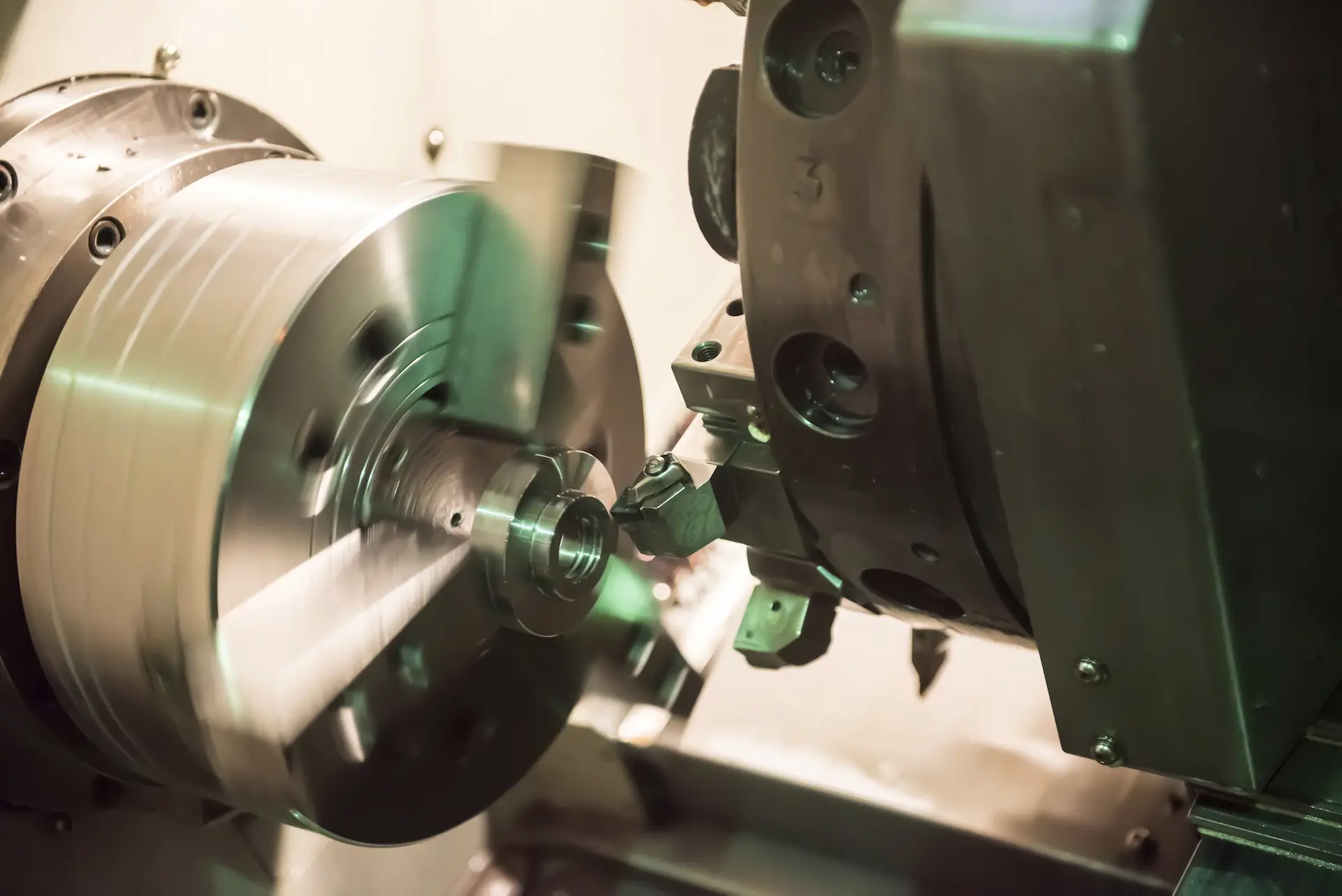

1. CNC Turning Service: The Backbone of Flywheel Precision

CNC Turning Service allows for the creation of flywheels with tight tolerances and precise geometries. CNCRUSH’s advanced CNC turning machines ensure each CNC Turned part meets the stringent requirements of automotive and industrial applications.

Positive sentiment: Reliable CNC Turning significantly enhances engine performance and operational safety.

Table 1: Typical CNC Turning Tolerances for Flywheels

| Process | Tolerance (mm) | Surface Finish (Ra µm) |

|---|---|---|

| CNC Turning | ±0.005 | 0.2–0.4 |

| CNC Milling | ±0.01 | 0.4–0.8 |

| Balancing | ±0.002 | – |

2. Material Selection: Maximizing Flywheel Performance

Flywheels can be made from cast iron, steel, or aluminum alloys. Material choice affects weight, rotational inertia, and wear resistance. CNCRUSH carefully selects materials to optimize both CNC Milled parts and CNC Turned parts, enhancing flywheel durability and efficiency in automotive, machine building, and automation applications.

Positive sentiment: Choosing premium materials ensures long-lasting performance under high stress.

3. Dimensional Accuracy in CNC Turning

Precision is critical. Even minor deviations in diameter or thickness can lead to imbalance or vibration. CNCRUSH uses high-precision CNC Turning and quality control protocols, including coordinate measuring machines (CMM), to guarantee that CNC Turned parts maintain exact specifications.

4. Surface Finish Optimization

The surface finish of flywheels affects friction, heat dissipation, and rotational efficiency. CNC Turning allows for ultra-smooth surfaces, reducing wear and enhancing longevity. CNCRUSH’s CNC Milled parts and CNC Turned parts achieve Ra values suitable for demanding automotive and industrial applications.

5. Balancing and Vibration Control

Flywheels must be dynamically balanced to prevent vibrations that can damage engines. CNCRUSH integrates balancing techniques with CNC Turning Service, ensuring that each CNC Turned part functions flawlessly in high-speed machinery.

Table 2: Flywheel Balancing Standards

| Flywheel Type | Max Unbalance (g·mm) | Recommended Surface Finish (Ra µm) |

|---|---|---|

| Automotive | 3 | 0.4–0.6 |

| Industrial | 5 | 0.6–0.8 |

| Heavy Equipment | 10 | 0.8–1.0 |

6. Heat Treatment for Strength and Wear Resistance

Heat treatment enhances the mechanical properties of flywheels. Processes such as quenching, tempering, and stress relieving increase hardness, reduce residual stresses, and improve fatigue resistance. CNCRUSH applies precise heat treatment protocols to both CNC Milled parts and CNC Turned parts.

Positive sentiment: Proper heat treatment extends flywheel life, reducing maintenance costs.

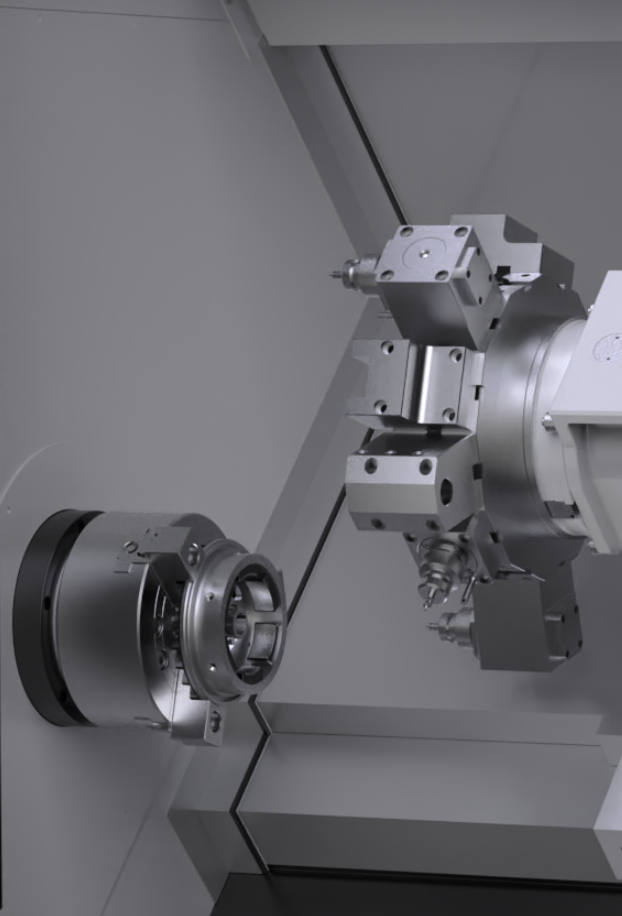

7. CNC Turning for Large-Diameter Flywheels

Handling large-diameter flywheels requires specialized CNC precision Turning machines. CNCRUSH’s equipment can process oversized components while maintaining tight tolerances and high surface finish, supporting machine building and automotive applications.

Negative sentiment: Inaccurate CNC precision Turning of large flywheels can cause catastrophic imbalance, leading to operational failures.

8. Integration with Automotive, Machine Building, and Automation Systems

Flywheels connect directly with engines, transmissions, and industrial machinery. CNC Turning Service ensures precise fit and optimal performance. CNCRUSH delivers CNC Milled parts and CNC Turned parts that meet the rigorous standards of automotive, machine building, and automation industries.

9. Challenges in CNC Turning and Solutions

Common challenges include tool deflection, thermal expansion, and surface imperfections. CNCRUSH mitigates these issues through advanced toolpath planning, high-rigidity machines, and continuous monitoring, ensuring high-quality CNC Turned parts and CNC Milled parts.

10. Future Trends in High-Precision CNC Turning

The push toward lightweight, high-strength, and balanced flywheels continues. Multi-axis CNC precision Turning, adaptive toolpaths, and advanced material science will further enhance precision. CNCRUSH is committed to providing innovative CNC precision Turning Service for evolving automotive, machine building, and automation applications.

FAQ

Q1: What is the difference between CNC Milled parts and CNC Turned parts for flywheels?

A1: CNC Milled parts are shaped by cutting a stationary workpiece with rotary tools, while CNC Turned parts are produced by rotating the workpiece against a cutting tool. Both are essential for high-precision flywheels.

Q2: Why is balancing critical in flywheel CNC precision Turning?

A2: Proper balancing prevents vibrations that could damage engines or industrial machines. CNCRUSH ensures dynamic balance in every CNC Turned part.

Q3: Can CNCRUSH handle large-scale or complex flywheel orders?

A3: Yes. CNCRUSH provides scalable CNC Turning Service for both small and large batch production, delivering precision CNC Milled parts and CNC Turned parts worldwide.