CNC Machining revolutionizes high-volume production. Discover 7 powerful strategies that optimize cycle times, reduce setup times, and enhance CNC Milled parts and CNC Turned parts quality for automotive, machine building, and autumotion.

CNC Machining stands as the backbone of modern manufacturing, driving unprecedented efficiency and precision in high-volume production environments. This comprehensive guide draws on insights from industry-leading resources—ranging from Makerverse’s analysis of high-volume CNC machining challenges to expert discussions on reducing cycle times on Practical Machinist—and integrates our own 12 years of experience at CNCRUSH. As a leading Chinese factory specializing in cnc machining service, we produce top-quality CNC Milled parts and CNC Turned parts for sectors such as automotive, machine building, and automotion. In the following sections, we summarize key takeaways from these sources and delve into 10 in-depth discussion topics, each exploring a critical facet of high-volume production optimization through CNC Machining.

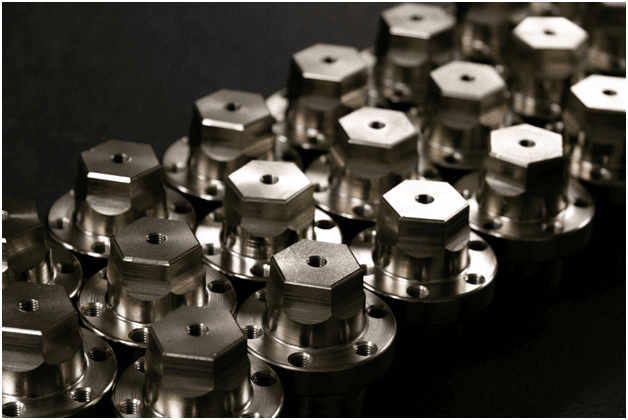

1. Introduction: The Power of CNC Machining in High-Volume Production

High-volume production demands rigorous process control, rapid cycle times, and exceptional quality. CNC Machining has emerged as a transformative force in this arena, enabling manufacturers to produce consistent, high-quality parts at scale. From reducing setup times to integrating advanced automation, the benefits of CNC Machining extend to every phase of production. Our discussion begins with an overview of how CNC Machining underpins efficient manufacturing and why its impact is particularly profound in sectors such as automotive, machine building, and automotion.

Key points include:

- Efficiency and Precision: CNC Machining facilitates repeatability and precision in mass production.

- Reduced Downtime: By streamlining operations, cycle times and setup times are significantly cut.

- Enhanced Quality: The digital control inherent in CNC processes leads to consistent quality across CNC Milled parts and CNC Turned parts.

At CNCRUSH, our state-of-the-art facility in China has leveraged these advantages to provide unmatched cnc machining service for over 12 years, setting a benchmark for excellence in high-volume production.

2. The Role of cnc machining service in Accelerating Production

High-volume production environments require rapid, efficient workflows to meet market demands. A robust cnc machining service can be the differentiator between lagging production and market leadership. Manufacturers face several challenges, such as equipment downtime, prolonged setup times, and quality inconsistencies. By investing in cutting-edge CNC Machining technology and expertise, companies can overcome these hurdles.

Key Benefits:

- Increased Throughput: Automation and precision control speed up production cycles.

- Consistency: Digital programming minimizes human error, ensuring consistent quality in every part.

- Flexibility: Quick changeovers and adaptability to different production runs are essential for high-volume demands.

Manufacturers across industries—from automotive to machine building—rely on advanced cnc machining service providers like CNCRUSH to meet their production targets without compromising on quality. The emotional sentiment here is overwhelmingly positive, as reducing production delays leads to increased customer satisfaction and competitive advantage.

3. Precision Engineering: Optimizing CNC Milled parts for High-Volume Needs

For high-volume production, the quality and precision of CNC Milled parts are paramount. Precision engineering ensures that every milled component adheres to strict tolerances, which is crucial when these parts are assembled into larger systems.

Analysis:

- Surface Finish and Tolerances: Optimized CNC milling results in superior surface finishes and tight tolerances, which reduce the need for secondary operations.

- Toolpath Optimization: Advanced software and simulation techniques enable better toolpath planning, leading to reduced cycle times and improved part accuracy.

- Material Utilization: Precision machining minimizes waste, which is essential for cost control in high-volume production.

At CNCRUSH, our advanced CNC machining technology ensures that each CNC Milled part is produced with a high level of precision. This translates into improved performance in applications ranging from automotive components to intricate machine building parts.

4. Efficiency Boost: Leveraging CNC Turned parts in Production Lines

While milling is critical for many components, turning plays a vital role in manufacturing parts with rotational symmetry. CNC Turned parts are integral in creating components such as shafts, housings, and fasteners, which require both high precision and efficient production.

Key Considerations:

- Geometric Complexity: CNC turning excels at handling complex geometries, ensuring a smooth finish on curved surfaces.

- Cycle Time Reduction: Advanced turning techniques and optimized cutting strategies help reduce cycle times significantly.

- Integration with Other Processes: CNC turning can be seamlessly integrated with milling operations to produce hybrid parts with complex features.

By utilizing high-quality CNC Turned parts, manufacturers can achieve significant efficiency gains in production lines. CNCRUSH’s commitment to excellence in cnc machining service guarantees that every turned component meets the rigorous demands of high-volume production, resulting in a positive impact on overall operational efficiency.

5. Overcoming Challenges in High-Volume Production with cnc machining service

High-volume production comes with a unique set of challenges that require innovative solutions. The most common issues include prolonged setup times, inconsistent part quality, and equipment downtime. A proactive approach in cnc machining service is critical to overcoming these obstacles.

Challenges and Solutions:

| Challenge | Solution | Impact |

|---|---|---|

| Prolonged Setup Times | Implementation of quick-change tooling and automation | Reduced downtime and faster transitions |

| Quality Inconsistencies | Adoption of advanced monitoring and inline quality checks | Consistent product quality |

| Equipment Downtime | Preventive maintenance and real-time diagnostics | Increased uptime and reliability |

| High Labor Costs | Integration of automation and digital control systems | Lower operational costs |

Table 1: Challenges in High-Volume Production and Corresponding Solutions

By addressing these challenges through state-of-the-art cnc machining service, companies can boost efficiency and maintain high production volumes. At CNCRUSH, our continuous improvement initiatives and investment in the latest technology ensure minimal disruptions in production—a sentiment that resonates positively with our clients.

6. Reducing Setup Times and Cycle Times with cnc machining service

One of the most critical factors in high-volume production is the reduction of setup and cycle times. Every minute saved in production can lead to significant cost savings and improved throughput.

Key Strategies:

- Modular Fixtures and Quick-Change Tooling: Using fixtures that allow for rapid tool changes can drastically reduce setup times.

- Automation Integration: Incorporating robotics and automated material handling systems minimizes human intervention, cutting cycle times.

- Process Standardization: Streamlining processes through standard operating procedures (SOPs) ensures consistency and speeds up production.

Table 2: Comparison of Setup and Cycle Time Reduction Strategies

| Strategy | Benefits | Implementation Example |

|---|---|---|

| Modular Fixtures | Fast changeovers and reduced setup time | Use of quick-release clamps and standardized jigs |

| Automation Integration | Minimizes manual errors and increases speed | Robotic arms for loading/unloading parts |

| Process Standardization | Consistency and predictability | Developing SOPs for each production stage |

| Preventive Maintenance | Less unplanned downtime | Regular equipment checks and maintenance schedules |

Table 2: Effective Strategies to Reduce Setup and Cycle Times in High-Volume Production

Reducing setup and cycle times is not only about operational efficiency but also about maintaining a competitive edge in high-volume manufacturing. CNCRUSH’s expertise in cnc machining service ensures that every process is optimized to deliver superior performance and rapid production cycles, a benefit that translates into a strong positive sentiment among our clients.

7. Integrating Automation and Digital Technologies in CNC Milled parts Production

The integration of automation and digital technologies has revolutionized the production of CNC Milled parts. In high-volume settings, these advancements facilitate continuous improvement and rapid scalability.

Digital and Automation Innovations:

- Digital Twins and Simulation: Using digital twins for simulation allows manufacturers to predict potential issues before production begins, optimizing tool paths and process parameters.

- IoT and Real-Time Monitoring: Sensors and IoT devices provide real-time data on machine performance, enabling immediate adjustments to ensure optimal efficiency.

- Robotic Automation: Robots can handle repetitive tasks, from loading raw materials to unloading finished parts, which significantly reduces labor costs and errors.

The combination of these digital tools and automation technologies enhances the production quality of CNC Milled parts and reinforces the reliability of high-volume production lines. At CNCRUSH, we integrate these innovations into our cnc machining service to deliver unparalleled precision and efficiency to industries such as automotive, machine building, and automotion.

8. Quality Control: Ensuring Superior CNC Turned parts for Reliability

Quality control remains a cornerstone of high-volume production, particularly when producing CNC Turned parts that require exacting tolerances and consistent finishes.

Quality Assurance Practices:

- Inline Inspection Systems: Utilizing cameras and laser measurement systems during production helps in the early detection of defects.

- Statistical Process Control (SPC): Implementing SPC methods ensures that production processes remain within predefined quality limits.

- Continuous Training and Certification: Regular training for machine operators on the latest quality control techniques ensures high standards are maintained.

By embedding rigorous quality control measures into the production of CNC Turned parts, manufacturers can significantly reduce rework and scrap rates, leading to a more efficient production cycle. CNCRUSH’s focus on quality in our cnc machining service has earned us a reputation for reliability and excellence among our global clientele.

9. Cost Optimization and Efficiency: High-Volume Production Strategies

In high-volume production, cost optimization is as critical as maintaining product quality. Strategies that improve efficiency directly translate into lower production costs and higher profitability.

Cost-Effective Strategies:

- Lean Manufacturing Principles: Streamlining processes to eliminate waste and optimize resource use.

- Economies of Scale: High production volumes allow for the distribution of fixed costs over a larger number of units, reducing the cost per part.

- Energy-Efficient Technologies: Investing in energy-efficient machines and processes can lead to significant savings over time.

- Outsourcing Non-Core Activities: By focusing on core competencies, companies can outsource ancillary tasks to specialists, further driving down costs.

These strategies, when combined with the precision of CNC Machining, allow manufacturers to balance cost and quality effectively. CNCRUSH leverages these principles within our cnc machining service framework to provide high-quality CNC Milled parts and CNC Turned parts that meet the stringent requirements of automotive, machine building, and automotion industries—resulting in a highly positive impact on our clients’ bottom lines.

10. Future Trends and Innovations in CNC Machining for Automotive, Machine Building and Automotion

The landscape of high-volume production is continuously evolving. Future trends in CNC Machining are expected to further optimize production processes and enhance product quality in industries such as automotive, machine building, and automotion.

Emerging Trends:

- Advanced Materials Processing: New alloys and composite materials require innovative machining techniques, pushing the boundaries of what CNC Machining can achieve.

- Artificial Intelligence and Machine Learning: These technologies enable predictive maintenance, process optimization, and smarter scheduling, which are crucial for maintaining high throughput.

- Sustainable Manufacturing: There is a growing emphasis on eco-friendly processes, including the use of renewable energy sources and waste minimization strategies.

- Collaborative Robotics (Cobots): The integration of cobots in production lines allows human operators and machines to work in harmony, combining human insight with robotic precision.

These trends promise to revolutionize the way high-volume production is approached, ensuring that CNC Machining remains at the forefront of industrial innovation. At CNCRUSH, we continuously invest in research and technology to adapt to these emerging trends, reinforcing our position as a leader in cnc machining service for CNC Milled parts and CNC Turned parts in high-demand sectors.

FAQ

Q1: What makes CNC Machining ideal for high-volume production?

A1: CNC Machining offers unparalleled precision, repeatability, and automation capabilities that are essential for producing large quantities of high-quality parts with minimal variation.

Q2: How does CNCRUSH ensure quality in its cnc machining service?

A2: CNCRUSH employs advanced quality control measures such as inline inspections, SPC, and rigorous operator training to ensure that every CNC Milled part and CNC Turned part meets strict quality standards.

Q3: What strategies are used to reduce setup times in high-volume production?

A3: Strategies include modular fixtures, quick-change tooling, automation integration, and process standardization, all of which contribute to faster changeovers and reduced downtime.

Q4: How do automation and digital technologies enhance high-volume production?

A4: They enable real-time monitoring, predictive maintenance, and digital simulation, which optimize process parameters, reduce errors, and increase overall production efficiency.

Q5: Why should manufacturers consider CNCRUSH for their high-volume production needs?

A5: With over 12 years of expertise in cnc machining service, CNCRUSH provides state-of-the-art solutions for producing precise CNC Milled parts and CNC Turned parts. Our commitment to quality, innovation, and cost efficiency makes us a trusted partner for industries such as automotive, machine building, and automotion.

Final Thoughts

The future of high-volume production is bright, driven by continuous improvements in CNC Machining technology and innovative strategies that optimize every facet of manufacturing. From reducing setup and cycle times to integrating advanced automation and digital technologies, the benefits are clear: increased efficiency, superior quality, and significant cost savings.

At CNCRUSH, our 12 years of industry experience have positioned us at the forefront of cnc machining service, delivering exceptional CNC Milled parts and CNC Turned parts that meet the rigorous demands of automotive, machine building, and automotion sectors. Our commitment to excellence and innovation is evident in every project we undertake, ensuring that our clients stay ahead in a competitive market.

Embrace the transformative power of CNC Machining to supercharge your high-volume production and achieve operational excellence. Whether you are looking to optimize your production line, reduce costs, or improve product quality, the strategies outlined in this guide provide a roadmap to success. Join the growing number of manufacturers who have discovered the benefits of advanced CNC Machining techniques and experience the difference that precision engineering can make in your production process.

Explore our website to learn more about our services and discover how CNCRUSH can help you achieve unprecedented efficiency and quality in your manufacturing operations. With our cutting-edge cnc machining service, you gain a partner committed to delivering the highest standards in CNC Milled parts and CNC Turned parts—ensuring that your production line remains agile, competitive, and ready to meet the future.