CNC Machining (Computer Numerical Control) has become a cornerstone of modern manufacturing, particularly in the automotive industry. This article delves into the evolution of CNC machining, highlighting its history, technological advancements, and the critical role it plays in automotive manufacturing today. Understanding this evolution is crucial for businesses looking to enhance their production capabilities and for those seeking professional CNC machining services.

CNC machining originated during World War II, initially aimed at improving production efficiency. Over decades, it has evolved from rudimentary systems to highly sophisticated machines capable of producing complex components with unparalleled precision. This evolution is characterized by advancements in technology, such as the introduction of microprocessors and CAD/CAM systems. As automotive manufacturing demands higher precision and efficiency, CNC machining has adapted, offering specialized services like CNC milled parts and CNC turned parts.

1. The Birth of CNC Machining

CNC machining traces its roots back to the 1940s, when the need for increased production speed and accuracy became paramount. The introduction of numerical control (NC) marked the beginning of this transformative journey. John T. Parsons is often credited as the father of CNC machining, pioneering the first NC machine to produce helicopter blades. This foundational technology laid the groundwork for what would become CNC machining, allowing for greater automation and efficiency.

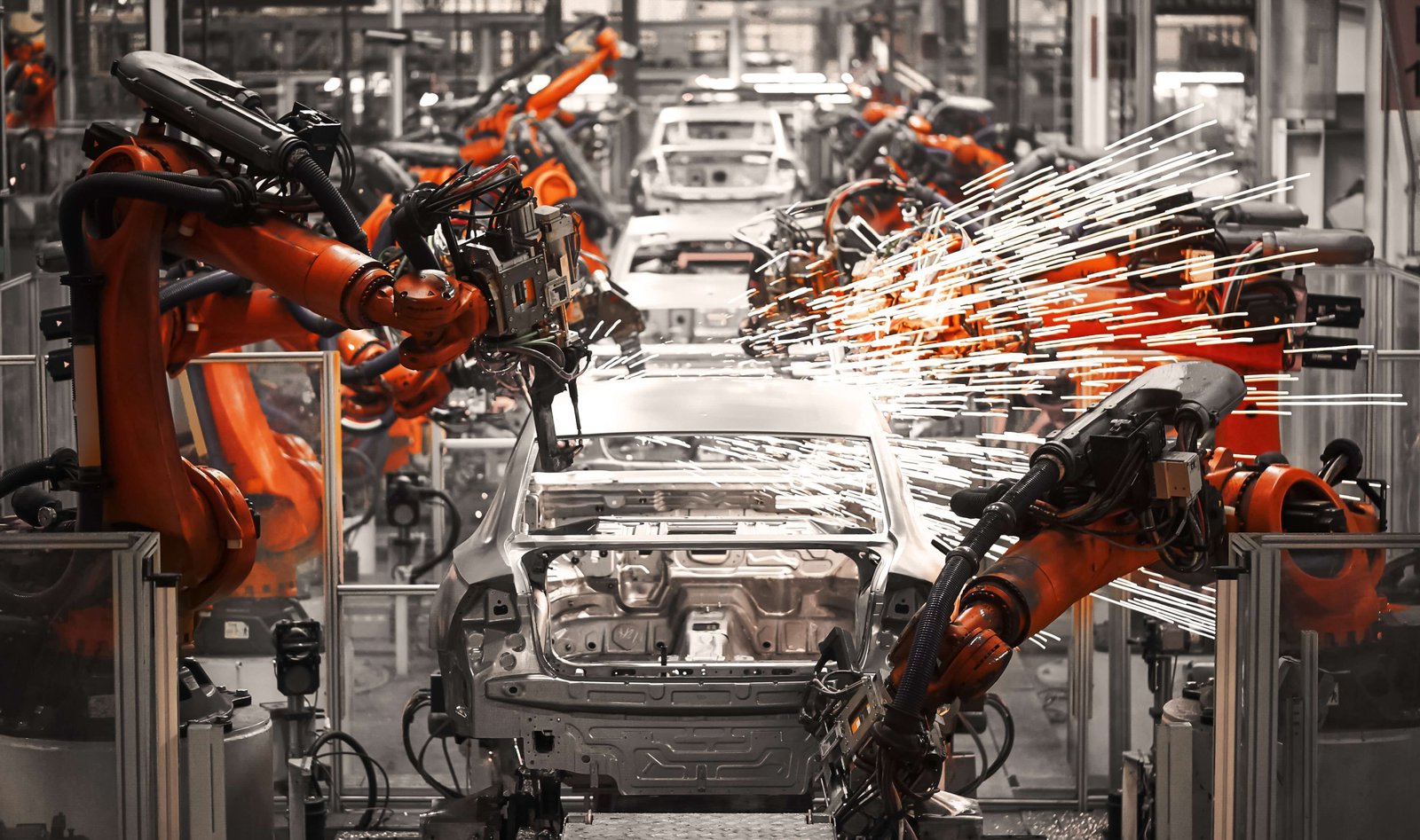

2. The Role of CNC in Automotive Manufacturing

Automotive manufacturing was one of the first industries to adopt CNC technology extensively. The ability to produce complex shapes and components with high precision revolutionized how automotive parts were made. This evolution not only improved production speed but also ensured consistent quality, which is critical in the automotive sector where safety and reliability are paramount.

3. Advancements in CNC Technology

Over the years, CNC machining has witnessed significant technological advancements. The introduction of computer control systems in the 1960s allowed for more sophisticated programming and operation of CNC machines. The transition from simple numerical control to full computer control has enabled manufacturers to achieve intricate designs and rapid production times.

Table 1: Key Milestones in CNC Technology

| Year | Milestone | Description |

|---|---|---|

| 1940s | Birth of NC | Introduction of numerical control in manufacturing. |

| 1960s | Computer Control | Transition from NC to CNC, enhancing precision. |

| 1980s | CAD/CAM Integration | Combining design and manufacturing processes. |

| 2000s | Automation and Robotics | Increased automation through robotics and AI. |

4. The Impact of CAD/CAM on CNC Machining

The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) has further revolutionized CNC machining. These technologies allow for seamless transition from design to manufacturing, enabling engineers to create complex components quickly and efficiently. This capability is particularly beneficial in the automotive industry, where the ability to rapidly prototype and iterate designs can significantly reduce time-to-market.

5. Precision and Efficiency: The Core Advantages of CNC Machining

CNC machining offers several advantages that are crucial for automotive manufacturing. Its ability to produce highly precise components with minimal waste is a game-changer. The automation inherent in CNC processes reduces human error, ensuring that parts meet strict specifications consistently. For manufacturers, this translates into higher productivity and lower production costs.

6. CNC Milled Parts vs. CNC Turned Parts

In the automotive sector, both CNC milled parts and CNC turned parts are vital. CNC milling is ideal for producing complex shapes and contours, while CNC turning is used for cylindrical components. Understanding when to use each method is crucial for optimizing production efficiency and component performance.

Table 2: Comparison of CNC Milled and Turned Parts

| Feature | CNC Milled Parts | CNC Turned Parts |

|---|---|---|

| Shape | Complex shapes and flat surfaces | Cylindrical shapes |

| Production Speed | Slower, more setup required | Faster production |

| Precision | High precision for intricate details | High precision for uniform shapes |

7. The Future of CNC Machining in Automotive Manufacturing

Looking ahead, CNC machining in automotive manufacturing is poised for further advancements. The integration of artificial intelligence (AI) and machine learning can enhance the adaptability of CNC systems, allowing them to optimize production processes in real time. This evolution will further solidify CNC machining as an indispensable tool in the automotive industry.

8. Environmental Considerations in CNC Machining

As the automotive industry shifts toward sustainability, CNC machining can play a significant role. The precision and efficiency of CNC processes reduce material waste, and the ability to work with various materials, including sustainable options, can help manufacturers meet environmental goals.

9. Choosing the Right CNC Machining Service

When selecting a CNC machining service, it is essential to consider factors such as experience, technology, and quality control. CNCRUSH, with over 12 years of experience in providing CNC machining services, specializes in CNC milled parts and CNC turned parts. We cater to various industries, ensuring high-quality production that meets the stringent demands of automotive manufacturing.

10. Frequently Asked Questions (FAQs)

Q1: What is CNC machining?

CNC machining is a manufacturing process that utilizes computer-controlled machines to create precise parts and components from various materials.

Q2: What are CNC milled parts?

CNC milled parts are components created using CNC milling machines, which remove material from a workpiece to produce complex shapes and flat surfaces.

Q3: What are CNC turned parts?

CNC turned parts are cylindrical components produced using CNC turning machines, which rotate the workpiece against cutting tools to shape it.

Q4: How can CNC machining improve my production process?

CNC machining enhances production by increasing precision, reducing waste, and enabling faster manufacturing times, leading to greater efficiency and cost savings.

Q5: Why choose CNCRUSH for CNC machining services?

CNCRUSH offers high-quality CNC machining services with a focus on precision and customer satisfaction. With our extensive experience, we provide tailored solutions for your manufacturing needs.

Conclusion

The evolution of CNC machining has transformed automotive manufacturing, making it more efficient, precise, and adaptable. As we look to the future, the continued integration of advanced technologies will only enhance the capabilities of CNC machining. For those in need of professional CNC machining services, CNCRUSH stands ready to deliver high-quality CNC milled parts and CNC turned parts, ensuring your manufacturing processes meet the highest standards. Visit CNCRUSH to explore our services and discover how we can support your CNC machining needs.