Precision metalworking is a cornerstone of modern manufacturing, and CNC machining plays a critical role in advancing industries that rely on accuracy, efficiency, and reliability. As global demand for high-quality parts continues to rise, CNC machining offers a solution that ensures precision, versatility, and cost-effectiveness. In this article, we will delve into the vital role of CNC machining in precision metalworking, exploring how this technology shapes industries such as automotive, machine building, and automation.

For those seeking expert CNC machining services, CNCRUSH, a leading factory based in China, has been specializing in CNC milled parts and CNC turned parts for over 12 years. At CNCRUSH, we understand the importance of providing high-precision solutions that meet the complex needs of various industries. If you’re in search of quality CNC machining services, we invite you to visit our website at www.cncrush.com and discover how our expertise can help elevate your manufacturing projects.

Summary and impact of CNC Precision Metalworking

CNC machining, an acronym for Computer Numerical Control, involves the use of computer-controlled tools to shape and fabricate materials with high precision. This advanced manufacturing process has revolutionized the world of metalworking, allowing for the creation of parts and components with remarkable consistency and minimal waste. The role of CNC Precision Metalworking is pivotal, as it offers capabilities that traditional manual machining methods simply cannot match.

10 Key Discussions on CNC Machining in Precision Metalworking

1. What is CNC Machining and How Does It Work?

CNC machining utilizes pre-programmed computer software to control the movement of tools and machinery. The process involves the use of automated machines to cut, mill, drill, and turn materials like aluminum, steel, and plastics into desired shapes and sizes. Unlike manual machining, which relies on human intervention, CNC machining is fully automated, ensuring high precision and repeatability. This makes it particularly valuable for producing custom CNC Precision Metalworking solutions such as CNC milled parts and CNC turned parts, widely used in industries like automotive and machine building.

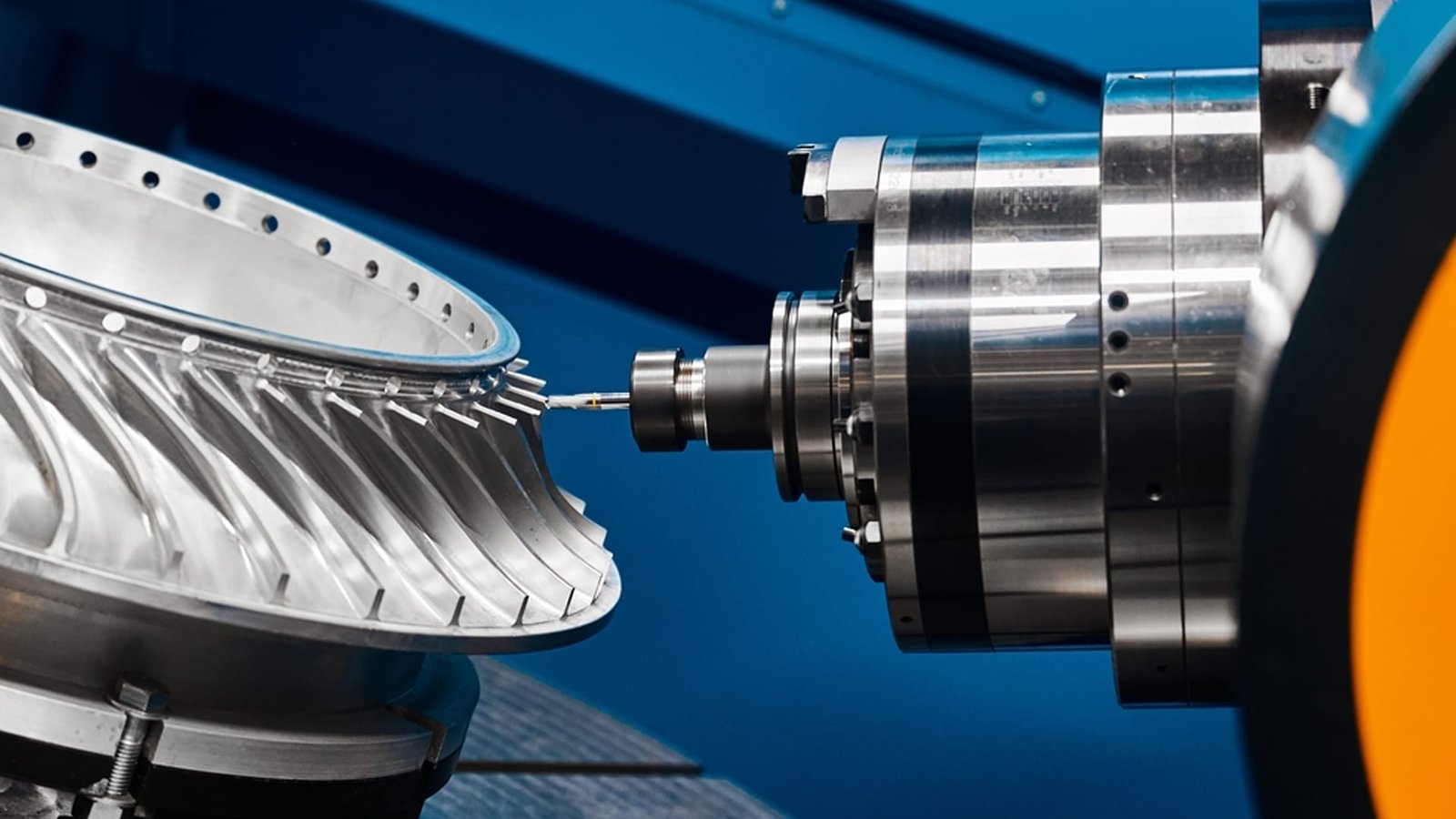

2. CNC Milled Parts: Enhancing Precision and Efficiency

CNC milling is one of the most common types of CNC Precision Metalworking and is essential for producing intricate parts with complex geometries. In CNC milling, rotating cutting tools are used to remove material from a workpiece, allowing for high-precision results. The ability to mill parts with fine details makes CNC milling an indispensable tool in industries that require precision, such as automotive, aerospace, and medical device manufacturing. At CNCRUSH, we specialize in delivering CNC milled parts that meet the highest standards of quality and accuracy.

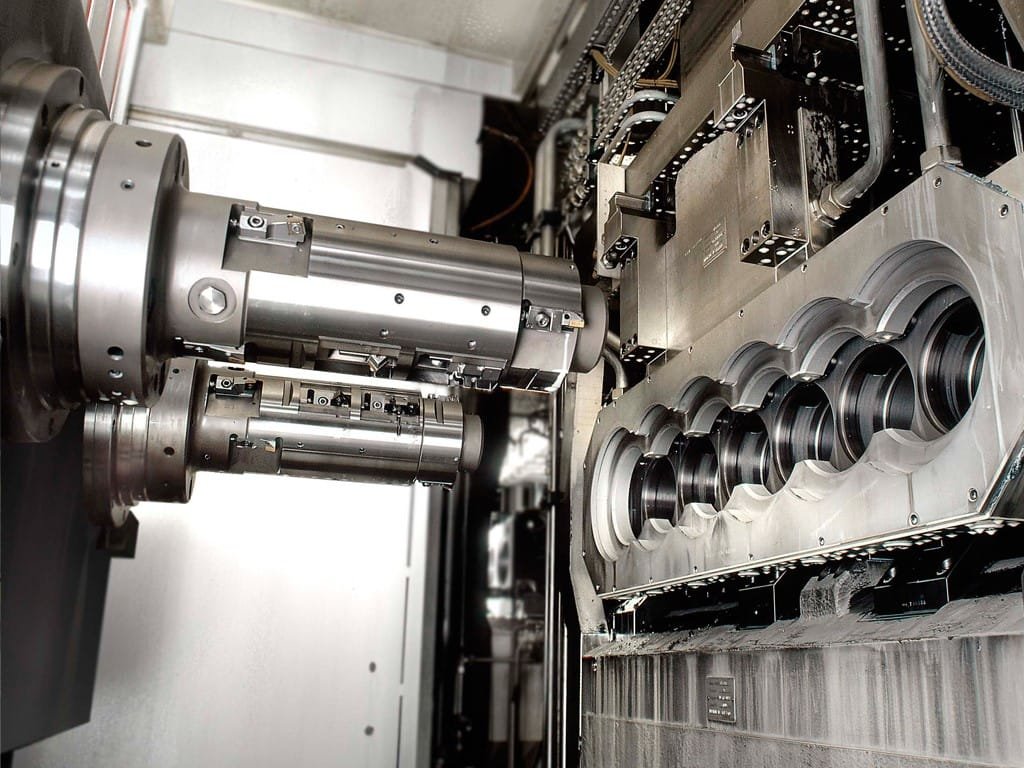

3. CNC Turned Parts: Achieving Symmetry and Consistency

CNC turning is another crucial aspect of CNC machining, specifically designed for producing cylindrical parts. This process involves rotating the workpiece while a stationary cutting tool removes material, creating symmetrical shapes. CNC turned parts are essential in applications where uniformity and precision are required, such as in machine building, automotive components, and automation. CNCRUSH offers CNC turned parts that are optimized for functionality and performance, ensuring superior results for clients in various industries.

4. The Role of CNC Machining in Automotive Manufacturing

The automotive industry relies heavily on CNC machining to produce high-precision components that are essential for vehicle performance and safety. From engine components to suspension parts, CNC machining ensures that each part meets stringent quality standards. CNC milled parts and CNC turned parts are frequently used in automotive manufacturing due to their ability to handle complex geometries and provide consistent results across high volumes of production. CNCRUSH has extensive experience serving the automotive sector, providing custom CNC Precision Metalworking solutions that contribute to the advancement of this critical industry.

5. CNC Machining in Machine Building: A Foundation for Innovation

Machine building is another industry where CNC machining has a transformative impact. The precision and versatility of CNC machining allow for the creation of custom parts that are integral to the design and operation of machinery. Whether it’s components for industrial machines or specialized equipment, CNC Precision Metalworking offers unparalleled accuracy in producing parts that fit together seamlessly. CNCRUSH supports machine building companies with high-quality CNC milled and turned parts that meet specific performance requirements, helping to drive innovation and efficiency in this sector.

6. Automation and CNC Machining: Revolutionizing Production Lines

Automation is increasingly becoming a staple in modern manufacturing, and CNC Precision Metalworking plays a key role in automating production lines. With the ability to operate 24/7 without sacrificing quality, CNC machining systems can increase production efficiency and reduce lead times. Automation in CNC machining not only improves throughput but also ensures consistency in the quality of the produced parts. CNCRUSH offers solutions that integrate CNC machining with automation, providing clients with faster production cycles and lower costs.

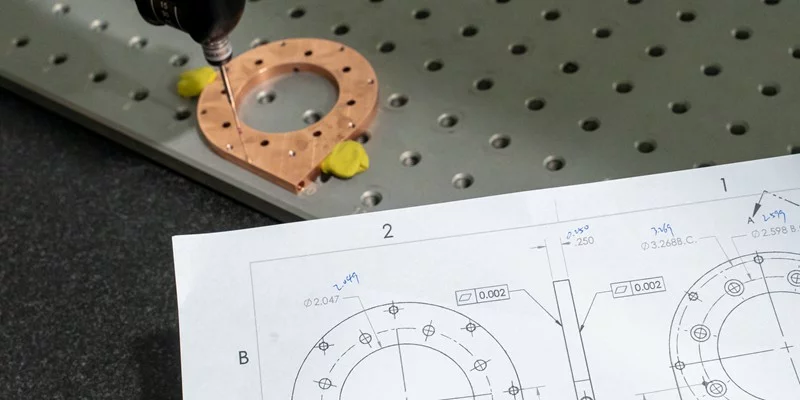

7. Why Precision Matters in CNC Machining for Metal Parts

Precision is at the core of CNC machining. For industries such as aerospace, automotive, and medical devices, the accuracy of each part is critical to the overall performance and safety of the end product. CNC machining ensures that even the most complex metal parts are produced to the tightest tolerances, preventing defects and minimizing the risk of failure. At CNCRUSH, we pride ourselves on delivering precision CNC machining services that exceed client expectations for CNC milled parts and CNC turned parts.

8. The Cost Benefits of CNC Machining for Metal Parts

While the initial investment in CNC machinery can be high, the long-term cost benefits of CNC machining are undeniable. CNC machining significantly reduces material waste, minimizes human error, and increases production speed, all of which contribute to cost savings. Furthermore, CNC machining allows for the efficient production of both small and large quantities, making it a highly adaptable solution for different project scales. CNCRUSH’s affordable CNC Precision Metalworking ensure that clients receive the best value for their investment, whether for prototypes or large production runs.

9. CNC Machining for Metal vs. Plastic Parts

CNC machining isn’t limited to metalworking; it also plays a vital role in producing plastic parts. CNC machining for plastic offers many of the same benefits as machining for metal, including high precision and low tolerance levels. This makes it suitable for applications such as electronics, medical devices, and consumer products. CNCRUSH is well-equipped to handle both CNC machining for metal parts and CNC plastic machining, ensuring that clients can source all their needs from a single, reliable supplier.

10. Future Trends in CNC Precision Metalworking

As technology continues to evolve, so too does the field of CNC machining. The future of CNC machining involves advancements in automation, artificial intelligence, and multi-axis machining, which will further increase efficiency and capabilities. These innovations are expected to enhance the precision, versatility, and speed of CNC machining, benefiting industries such as automotive, machine building, and automation. CNCRUSH remains at the forefront of these developments, continuously adopting the latest technologies to meet the evolving needs of our clients.

Table 1: CNC Machining Applications Across Industries

| Industry | CNC Machining Applications | Benefits |

|---|---|---|

| Automotive | Engine components, suspension parts, transmission components | High precision, safety, reliability |

| Machine Building | Industrial machines, specialized equipment | Custom solutions, performance |

| Aerospace | Aircraft components, engine parts | Tolerances, durability |

| Medical Devices | Surgical tools, prosthetics, implants | Precision, reliability |

| Consumer Electronics | Components for electronics, housings | High efficiency, small tolerances |

Table 2: Advantages of CNC Precision Metalworking

| Advantage | Description |

|---|---|

| Precision | Achieves tight tolerances, ensuring high-quality parts |

| Versatility | Handles a variety of materials, from metals to plastics |

| Speed | Shortens production time, enabling rapid prototyping |

| Consistency | Provides repeatable results across multiple production runs |

| Cost-effectiveness | Reduces waste, labor costs, and machine downtime |

FAQ: CNC Machining for Precision Metalworking

Q: What materials can be used for CNC machining?

A: CNC machining can handle a wide range of materials, including metals like aluminum, steel, brass, and titanium, as well as plastics and composites. At CNCRUSH, we specialize in CNC machining aluminum and steel parts, offering high-precision services for various industries.

Q: How accurate is CNC machining?

A: CNC machining offers exceptional accuracy, with tolerances typically within a few microns. This makes it ideal for producing components that require high precision, such as automotive and aerospace parts.

Q: What is the difference between CNC milled and CNC turned parts?

A: CNC milling is used to remove material from a workpiece using rotating tools, making it ideal for creating complex shapes. CNC turning, on the other hand, involves rotating the workpiece while a stationary cutting tool shapes it, making it ideal for producing cylindrical components.

Q: Can CNC machining handle large production runs?

A: Yes, CNC Precision Metalworking is highly efficient for both small and large production runs, ensuring consistent quality and fast turnaround times.

In conclusion, CNC machining is the backbone of precision metalworking, offering unparalleled benefits in terms of accuracy, efficiency, and versatility. Whether you’re in the automotive, machine building, or automation industry, CNC machining services provide the high-quality solutions you need to stay ahead in a competitive market. CNCRUSH, with over 12 years of experience in CNC milling and turning, is your trusted partner for all your CNC machining needs. Visit us at www.cncrush.com to learn more about our expertise and how we can support your next project.