CNC milling has become an essential technology in modern manufacturing, playing a critical role in industries such as automotive, aerospace, machine building, and automation. Over the past few decades, CNC (Computer Numerical Control) milling has revolutionized the production of precision parts and components. With a growing demand for high-quality, cost-effective, and reliable parts, CNC machining is increasingly favored for its accuracy, versatility, and efficiency. In this article, we will explore the significant benefits of CNC milling and its growing impact on the manufacturing industry, with a focus on CNC Milled and CNC Turned parts.

As a CNC machining company with over 12 years of experience, CNCRUSH specializes in providing high-precision CNC machining services. We are dedicated to delivering CNC milled parts and CNC turned parts for clients in various sectors, including automotive, machine building, and automation. With a state-of-the-art facility in China, we offer custom CNC solutions tailored to our clients’ needs. Whether you require aluminum, steel, brass, or plastic parts, CNCRUSH has the expertise to meet your specific requirements.

This article will dive deep into the importance of CNC milling and its transformative role in modern manufacturing. By the end, you’ll understand why CNC milling is at the forefront of precision manufacturing and why CNCRUSH should be your trusted CNC machining service provider.

1. Understanding CNC Milling and its Impact on Manufacturing

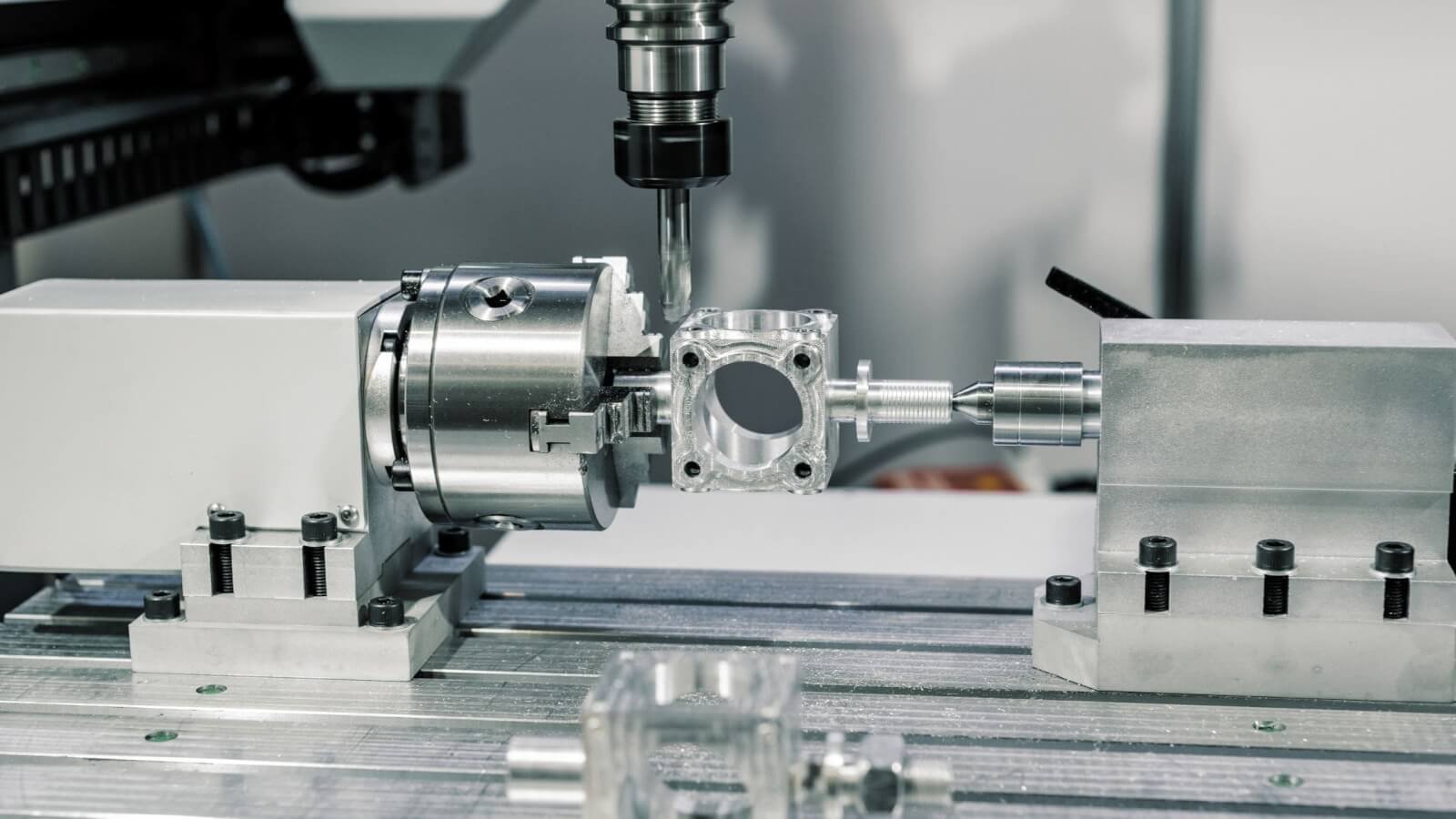

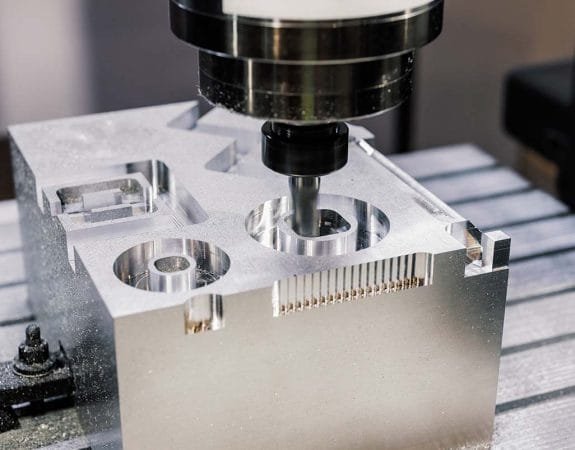

CNC milling is a subtractive manufacturing process that utilizes rotary cutters to remove material from a workpiece, producing custom shapes and precise parts. Unlike traditional manual milling, CNC milling is controlled by computer programs, allowing for high precision, repeatability, and faster production.

The ability to achieve tight tolerances and complex geometries makes CNC milling an ideal solution for industries such as aerospace, automotive, and machine building. Companies rely on CNC milling to produce everything from small components to large, intricate parts with exceptional accuracy.

At CNCRUSH, we utilize advanced CNC milling technology to create CNC milled parts with high precision, catering to industries like automotive, aerospace, and automation. Whether you’re looking for CNC milled aluminum parts or need CNC milled brass components, we have the skills and equipment to deliver.

2. The Evolution of CNC Milling in the Manufacturing Sector

In the early days of manufacturing, producing precise and complex parts was a time-consuming and labor-intensive task. However, the advent of CNC milling machines marked a significant shift, enabling manufacturers to achieve greater accuracy, consistency, and speed in their operations.

CNC milling machines have evolved significantly, now offering multi-axis capabilities that allow manufacturers to create complex geometries with ease. These advancements have revolutionized industries such as automotive, where high-performance parts demand high precision, and aerospace, where safety and durability are paramount.

As a leading CNC machining service provider, CNCRUSH has embraced these technological advancements, utilizing cutting-edge CNC milling machines to provide high-quality, cost-effective solutions for our clients.

3. Key Advantages of CNC Milling: Precision, Flexibility, and Efficiency

CNC milling offers a wide range of benefits that make it the go-to solution for many manufacturing needs. Here are some of the key advantages:

3.1. High Precision and Accuracy

One of the most significant advantages of CNC milling is its ability to produce parts with exceptional accuracy. CNC machines can work to tolerances as low as 0.001mm, ensuring that parts meet even the most stringent specifications. This is crucial in industries like aerospace and automotive, where even the slightest deviation in part dimensions can lead to catastrophic failure.

3.2. Versatility and Flexibility

CNC milling machines can handle a wide variety of materials, including metals, plastics, and composites. This makes them incredibly versatile, as they can be used to create parts for virtually any industry, including automotive, aerospace, and machine building.

3.3. Increased Production Efficiency

CNC milling allows for faster production times compared to traditional manufacturing methods. The ability to run machines autonomously, with minimal human intervention, leads to higher throughput and reduced labor costs. This efficiency is essential for companies that need to meet tight production deadlines.

At CNCRUSH, we pride ourselves on offering high-quality CNC milling services that deliver both precision and speed. Our CNC milled parts are used in industries ranging from automotive to machine building, providing reliable and durable solutions for our clients.

4. How CNC Milling is Shaping the Automotive Industry

The automotive industry is one of the primary sectors benefiting from CNC milling technology. With the increasing demand for complex, high-performance parts, manufacturers are turning to CNC machining to produce critical components such as engine blocks, suspension systems, and transmission parts.

CNC milling enables automotive manufacturers to create parts with tight tolerances and intricate designs, which are necessary for the high-performance vehicles that are becoming more common today. Whether it’s producing CNC milled aluminum parts for lightweight structures or CNC turned steel parts for engine components, CNC milling plays a key role in automotive manufacturing.

At CNCRUSH, we provide CNC machining services that cater to the automotive sector, producing both CNC milled and CNC turned parts for various automotive applications. Our expertise in CNC machining ensures that every part meets the high standards expected by our clients.

5. The Role of CNC Milling in Machine Building and Automation

Machine building and automation industries rely heavily on CNC milling for the production of high-precision components that are essential for machinery and automated systems. CNC milled parts are used in everything from industrial robots to manufacturing equipment, where precision and reliability are critical.

CNC milling allows manufacturers in the machine building and automation sectors to produce complex components that would be difficult or impossible to create using traditional methods. With CNC machines capable of handling multiple axes, intricate geometries can be easily achieved, ensuring that machines operate efficiently and with minimal downtime.

CNCRUSH offers custom CNC solutions for the machine building and automation industries, providing high-quality CNC milled and CNC turned parts for a wide range of applications.

6. CNC Milled Parts vs. CNC Turned Parts: Key Differences

While both CNC milled and CNC turned parts are produced using CNC machining technology, the processes differ in how material is removed and the types of parts they produce.

6.1. CNC Milled Parts

CNC milling involves removing material from a workpiece using rotary cutters. This process is ideal for creating parts with complex geometries, flat surfaces, and features like pockets, holes, and slots.

6.2. CNC Turned Parts

CNC turning, on the other hand, involves rotating a workpiece while a stationary cutting tool removes material. This process is typically used for creating cylindrical parts, such as shafts, gears, and bolts.

At CNCRUSH, we specialize in both CNC milled and CNC turned parts, offering a full range of services to meet the needs of our clients in various industries.

7. The Cost-Effectiveness of CNC Milling in Modern Manufacturing

While CNC precision milling may have a higher initial setup cost compared to traditional manufacturing methods, its long-term cost-effectiveness makes it an attractive option for many manufacturers. The precision and repeatability of CNC machines reduce the need for rework and waste, leading to cost savings over time.

Additionally, the speed and efficiency of CNC precision milling contribute to lower production costs, making it an ideal choice for large-scale manufacturing runs.

At CNCRUSH, we offer affordable CNC machining services without compromising on quality. We work with our clients to ensure that they receive the best value for their investment, whether they need CNC milled parts, CNC turned parts, or both.

8. Why Choose CNCRUSH for Your CNC Machining Needs?

As a professional CNC machining service provider with over 12 years of experience, CNCRUSH is dedicated to delivering high-quality CNC milled and CNC turned parts. Our China-based factory is equipped with advanced CNC machinery, allowing us to provide precise, custom solutions for our clients in various industries.

We understand the importance of reliable, cost-effective manufacturing and work closely with our clients to meet their specific needs. Whether you’re in the automotive, machine building, or automation industry, CNCRUSH has the expertise to provide CNC machining services that exceed your expectations.

9. CNC Milling for Prototyping: Speed and Precision in Product Development

One of the key advantages of CNC precision milling is its ability to quickly produce prototypes for product development. Precision milling allows manufacturers to create high-precision prototypes in a fraction of the time it would take using traditional methods.

This is especially beneficial in industries like automotive and machine building, where rapid prototyping is crucial for testing new designs and concepts.

CNCRUSH offers CNC prototype machining services, providing fast and reliable prototyping solutions for clients in various industries. Our expertise in CNC milling ensures that your prototypes meet the highest standards of quality and precision.

10. The Future of CNC Milling in Manufacturing

The future of CNC milling looks bright, with continued advancements in technology and automation. As industries demand even higher precision and more complex parts, precision milling will remain at the forefront of manufacturing innovation.

With the integration of AI and machine learning, CNC machines will continue to improve in terms of speed, accuracy, and efficiency, enabling manufacturers to produce even more intricate and precise parts.

At CNCRUSH, we are committed to staying ahead of the curve and offering the latest in CNC milled technology. Our goal is to provide the best CNC machining services for our clients, ensuring that they remain competitive in an ever-evolving market.

FAQ: Common Questions About CNC Milling

Q1: What is CNC milling? A1: CNC milling is a manufacturing process that uses rotary cutters to remove material from a workpiece. It is used to produce parts with complex geometries, high precision, and intricate features.

Q2: How does CNC milling differ from CNC turning? A2: CNC milling involves rotating cutters to remove material from a workpiece, while CNC turning involves rotating the workpiece itself while a stationary cutting tool removes material. Milling is ideal for flat or complex parts, while turning is best suited for cylindrical components.

Q3: What industries benefit from CNC milling? A3: CNC milling is used in various industries, including automotive, aerospace, machine building, and automation, where precision and reliability are critical.

By focusing on CNC milling, CNCRUSH is positioned to offer cutting-edge solutions in precision CNC machining. For CNC milled parts, CNC turned parts, and custom CNC solutions, visit our website CNCRUSH today!