Automotive parts production is at the heart of the modern automotive industry, providing the components that power everything from engines to electrical systems. As automotive technology continues to evolve, the demand for precision, reliability, and efficiency increases. CNC machining, which stands for Computer Numerical Control machining, has become one of the most important methods for producing high-quality automotive parts. As a provider of CNC machining services for over 12 years, CNCRUSH specializes in delivering CNC Milled parts and CNC Turned parts for the automotive industry. This article will explore the crucial role of CNC machining in automotive manufacturing, highlighting 10 powerful ways it transforms the production of automotive components.

1. Precision in Automotive Parts Design: Ensuring Accuracy in Every Component

The primary reason that CNC machining is indispensable in automotive parts production is its ability to achieve high levels of precision. Automotive components often have complex geometries, which require exact measurements to ensure they function as intended. Whether it’s engine parts, braking systems, or suspension components, CNC machining can achieve tolerances of up to ±0.005 mm, something traditional machining methods often cannot match.

For example, when manufacturing a component like a fuel injector, the size and shape of the holes must be extremely precise for proper fuel flow. CNC machining achieves this precision consistently, making it the ideal choice for Automotive Parts Production that meet strict quality standards. At CNCRUSH, our CNC milling and turning services ensure that automotive parts are made to the highest standards, providing durable, long-lasting components that support the efficiency and performance of the vehicle.

2. Increased Production Speed with Automation: Maximizing Efficiency

In the Automotive Parts Production industry, speed is crucial. The ability to produce large quantities of parts quickly without compromising on quality is essential. CNC machining automates many of the traditional manual tasks involved in part production, leading to faster turnaround times and increased efficiency.

Thanks to automation, CNC machines can work 24/7 without the need for breaks, ensuring that large production runs can be completed within tight time frames. CNCRUSH leverages this advantage by providing CNC Milled parts and CNC Turned parts for large-scale automotive production. Our efficient processes enable automotive manufacturers to meet demand while minimizing production delays.

3. Material Versatility: Tailoring Automotive Parts to the Right Material

Automotive parts are made from a variety of materials, each with its own set of properties. From lightweight aluminum alloys used in engine blocks to high-strength steel for safety-critical components, choosing the right material for each part is essential. CNC machining is highly adaptable and can process a wide range of materials, including aluminum, steel, brass, plastics, and composites.

CNCRUSH offers CNC machining services for a variety of automotive materials. Whether you need lightweight, corrosion-resistant aluminum components for vehicle exteriors or durable steel parts for the chassis, our CNC machines can handle the intricacies of these materials. Our extensive experience ensures that we can recommend the best material for each automotive part based on its intended application.

4. Consistency and Quality Control: Achieving Uniformity Across Every Part

One of the most significant challenges in Automotive Parts Production is maintaining uniformity in part production. Since automotive components must fit together precisely, even minor deviations in part size or shape can result in assembly issues. CNC machining excels in maintaining consistency, ensuring that each part produced meets the same stringent standards.

At CNCRUSH, our CNC machining services are supported by advanced inspection tools, such as Coordinate Measuring Machines (CMM), to ensure that each part meets the exact specifications. By minimizing human error, we can provide automotive manufacturers with parts that meet their rigorous quality and consistency requirements.

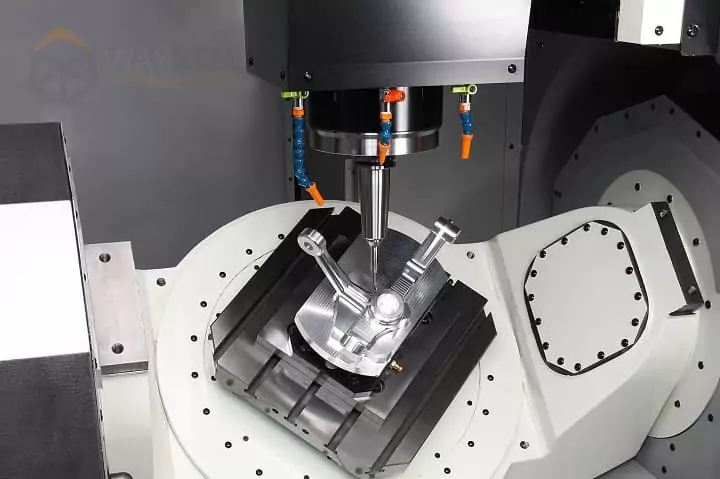

5. Complex Geometries and Intricate Designs: Automotive Parts Production with Advanced Features

Automotive design is becoming more complex, with engineers pushing the boundaries of innovation to improve vehicle performance and safety. CNC machining plays a pivotal role in producing parts with complex geometries and intricate features that would be difficult or impossible to achieve with traditional machining methods.

From custom gears and turbine blades to engine components with fine details, CNC machines are capable of creating complex parts with high precision. CNCRUSH specializes in creating CNC Milled parts with complex features, and our CNC Turning services can produce intricate parts like camshafts and steering columns, which are crucial in the automotive industry.

6. Prototype Development: Accelerating Product Design and Testing

Before mass production of automotive parts begins, prototypes are often developed to test their functionality, fit, and performance. CNC machining plays a crucial role in creating rapid prototypes that can be tested and refined before moving into full-scale production.

Using CNC machines, automotive manufacturers can produce accurate prototypes in a fraction of the time it would take using traditional methods. These prototypes allow engineers to test different designs and make necessary adjustments without the need for expensive tooling or retooling. At CNCRUSH, our CNC machining services support automotive companies by providing quick-turnaround prototypes that streamline product development.

7. Reduced Waste: Enhancing Sustainability in Automotive Parts Production

In the automotive industry, material waste is a major concern, both from an environmental and cost perspective. CNC machining offers significant advantages in reducing material waste compared to traditional manufacturing methods. Because CNC machines use digital controls, they can precisely cut, mill, and turn materials to exact specifications, minimizing excess material that would otherwise be discarded.

This not only lowers production costs but also contributes to more sustainable manufacturing processes. At CNCRUSH, we prioritize sustainability by using efficient CNC machining techniques that reduce material waste and help automotive manufacturers meet their environmental goals.

8. Cost-Effectiveness for High-Volume Automotive Parts Production: Balancing Quality and Budget

While the initial setup costs for CNC machining can be higher than traditional methods, the long-term benefits far outweigh these costs, especially for high-volume production runs. CNC machining minimizes labor costs and reduces material waste, leading to cost savings over time.

For automotive manufacturers looking to produce large quantities of parts, CNC machining provides a cost-effective solution without compromising on quality. At CNCRUSH, we help clients balance their budget with high-quality CNC Milled parts and CNC Turned parts that are produced at scale without sacrificing precision.

9. Customization and Flexibility: Tailored Solutions for Unique Automotive Applications

Each automotive part is designed for a specific purpose, and the ability to customize parts for unique applications is a critical factor in the industry. CNC machining offers unparalleled flexibility in creating custom parts that meet the unique needs of automotive manufacturers.

Whether it’s producing a custom bracket for a specialized vehicle model or a unique component for an electric vehicle, CNC machining allows for tailored solutions. At CNCRUSH, we provide CNC Automotive Parts Production services that can be customized for specific automotive applications, ensuring that every part we produce is designed to fit perfectly and function optimally.

10. Supporting the Future of Automotive Innovation: Enabling New Technologies

The automotive industry is continuously evolving, driven by the demand for new technologies such as electric vehicles, autonomous driving systems, and advanced safety features. CNC machining is at the forefront of these innovations, enabling the production of parts that support emerging technologies.

As automotive manufacturers explore new possibilities, CNC machining provides the precision and flexibility needed to bring these innovations to life. Whether it’s producing lightweight components for electric vehicles or precise sensors for autonomous driving, CNCRUSH’s CNC machining services are designed to support the future of Automotive Parts Production.

Table 2: Advantages of CNC Machining for Automotive Parts Production

| Benefit | Traditional Methods | CNC Machining |

|---|---|---|

| Precision | Low to Moderate | High |

| Speed | Slow | Fast |

| Customization | Limited | Extensive |

| Waste | High | Low |

| Cost-Effectiveness | Moderate | High (Long-term) |

Frequently Asked Questions (FAQ)

Q1: What types of automotive parts can be produced using CNC machining?

A: CNC machining can produce a wide range of automotive parts, including engine blocks, gears, shafts, brackets, and many other components used in various vehicle systems.

Q2: What materials are commonly used for Automotive Parts Production?

A: Common materials include aluminum alloys, steel, brass, and plastic composites, chosen for their durability, strength, and suitability for specific applications.

Q3: Can CNC machining help with prototyping automotive parts?

A: Yes, CNC machining is ideal for creating accurate prototypes, allowing automotive engineers to test and refine their designs before mass production.

Q4: How does CNC machining help reduce waste in Automotive Parts Production?

A: CNC machines are highly precise, which minimizes material waste by cutting only what is necessary, making them more sustainable than traditional methods.

Conclusion: The Unmatched Role of CNC Machining in Automotive Parts Production

CNC machining has revolutionized automotive parts production by offering precision, efficiency, and customization that traditional methods simply cannot match. From prototype development to high-volume production, CNC machining plays a pivotal role in creating the parts that drive the automotive industry forward. At CNCRUSH, we have over 12 years of experience in providing high-quality CNC Milled parts and CNC Turned parts for the automotive sector, offering tailored solutions that meet the demands of today’s advanced vehicles. Whether you need high-precision components or innovative designs