CNC machining has emerged as a cornerstone of aerospace manufacturing, enabling the production of precise, reliable, and complex components required for advanced aviation and aerospace systems. Its transformative capabilities support innovation, operational safety, and efficiency in one of the most demanding industries. For over 12 years, CNCRUSH, a trusted provider of CNC Milled parts and CNC Turned parts, has been crafting high-performance components for global aerospace leaders, leveraging our expertise to meet rigorous industry standards.

This article explores the pivotal role CNC machining plays in aerospace manufacturing, covering 10 critical aspects that define its significance.

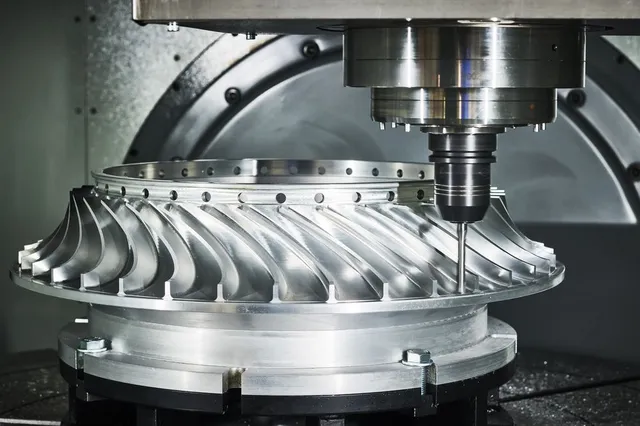

1. Unparalleled Precision: A Cornerstone of Aerospace Manufacturing

The aerospace industry demands components with tolerances as tight as ±0.001 inches, an accuracy that only CNC machining can consistently deliver. Turbine blades, engine casings, and intricate airframe assemblies exemplify the kind of parts where precision is critical. Even minor deviations in these components can lead to catastrophic failures.

CNC machining achieves such precision through computer-controlled movements of cutting tools that carve parts from raw materials with astonishing accuracy. Multiaxis CNC machines—such as 5-axis systems—can simultaneously operate along multiple planes, allowing for the creation of highly intricate designs while maintaining strict quality control.

At CNCRUSH, we use state-of-the-art CNC technology to produce precision-engineered components, ensuring our parts exceed industry benchmarks for quality and reliability.

2. The Lightweight Advantage: Enhancing Aircraft Efficiency

In aerospace, weight is directly tied to performance and efficiency. CNC machining enables the production of lightweight components by machining advanced materials such as titanium, aluminum, and composites. These materials are selected for their superior strength-to-weight ratios, enabling better fuel efficiency and payload capacities.

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Corrosion-resistant, lightweight | Fuselages, wing structures |

| Titanium | High strength, fatigue resistance | Engine components, landing gear parts |

| Composites | Customizable, lightweight | Frames, wing spars, fairings |

By leveraging CNC machining’s precision and versatility, CNCRUSH manufactures aerospace components that are not only lighter but also robust enough to endure the harsh environments of aviation and space travel.

3. Rapid Prototyping: Accelerating Innovation in Aerospace

The aerospace industry thrives on innovation, and rapid prototyping is critical for bringing new designs to life. CNC machining enables engineers to produce functional prototypes quickly, allowing them to test and refine designs with minimal delay.

Unlike traditional prototyping methods, CNC machining offers:

- Speed: Prototypes can be created within days, reducing the development cycle.

- Accuracy: CNC-machined prototypes closely mimic final products in design and functionality.

- Cost-efficiency: The precision of CNC machining minimizes material waste during prototyping.

At CNCRUSH, we specialize in rapid prototyping services, using advanced CNC Milled parts and CNC Turned parts to deliver prototypes that pave the way for aerospace innovation.

4. Five-Axis Machining: Unlocking Complex Geometries

Five-axis CNC machining has revolutionized aerospace manufacturing by enabling the production of highly complex components with fewer setups and enhanced precision. With five degrees of freedom, the cutting tool can approach the workpiece from virtually any angle, making it ideal for creating aerodynamic parts like winglets, turbine blades, and intricate housings.

Key Benefits of Five-Axis Machining in Aerospace:

- Fewer Setups: Complex geometries are machined in a single operation, reducing lead times.

- Enhanced Surface Quality: Superior finishes reduce the need for post-processing.

- Precision Across All Axes: Every angle and curve is machined with micrometer-level accuracy.

By utilizing advanced 5-axis CNC systems, CNCRUSH ensures efficient and cost-effective production of complex aerospace parts.

5. Durability Under Extreme Conditions: Ensuring Aerospace Safety

Aerospace components must withstand extreme environmental conditions, from intense heat in jet engines to high pressures at cruising altitudes. CNC machining is indispensable for creating parts that meet these durability requirements, especially when using advanced alloys like Inconel or titanium.

At CNCRUSH, our rigorous machining processes ensure that every part, whether structural or mechanical, performs reliably under the most demanding conditions.

6. Customization for Avionics and Electrical Systems

Avionics systems require precise, compact, and reliable components to support critical operations such as navigation, communication, and flight control. CNC machining enables the creation of intricate enclosures, connectors, and mounting systems tailored to specific avionics applications.

Our custom CNC machining services deliver high-performance solutions for avionics, ensuring seamless integration and unmatched reliability.

7. Material Optimization for Cost Savings

The aerospace sector deals with high-cost materials like titanium and composite resins. CNC machining minimizes waste through precise programming and efficient cutting strategies, optimizing material usage without compromising quality.

At CNCRUSH, our approach to CNC machining focuses on material efficiency, helping aerospace manufacturers reduce costs while maintaining the highest standards of production.

8. Applications in Maintenance, Repair, and Overhaul (MRO)

CNC machining is invaluable for MRO operations, enabling the refurbishment of worn or damaged parts. From repairing engine components to restoring landing gear, CNC machining provides accurate, repeatable solutions that extend the lifespan of critical aerospace systems.

With our extensive experience in CNC Turned parts, CNCRUSH offers reliable MRO solutions that keep aerospace fleets operational and safe.

9. Driving Aerospace Innovation Through CNC Machining

CNC machining empowers aerospace engineers to explore groundbreaking designs, from lightweight materials to advanced propulsion systems. By enabling precision manufacturing of these cutting-edge components, CNC machining drives progress in areas like fuel efficiency, safety, and sustainability.

At CNCRUSH, we are committed to pushing the boundaries of what’s possible in aerospace manufacturing, providing our clients with the tools to lead the industry forward.

10. Future Trends in CNC Machining for Aerospace

The integration of AI and IoT technologies is set to redefine CNC manufacturing in aerospace. Smart machines equipped with predictive maintenance and cloud-based monitoring will further enhance efficiency and reliability.

CNCRUSH is actively investing in these technologies, ensuring our clients benefit from the most advanced CNC manufacturing solutions available.

FAQ: CNC Machining in Aerospace

Q1: What is CNC machining’s role in aerospace innovation?

A: CNC machining supports aerospace innovation by enabling the production of intricate, high-precision components.

Q2: Why is CNCRUSH a trusted partner for aerospace CNC manufacturing?

A: With over 12 years of experience, CNCRUSH delivers world-class CNC Milled parts and CNC Turned parts tailored to aerospace requirements.

Q3: How does CNC machining support rapid prototyping?

A: It allows engineers to quickly create accurate prototypes for testing, significantly reducing development cycles.

Why CNCRUSH is Your Ideal Partner in Aerospace Manufacturing

As a trusted China CNC factory, CNCRUSH combines advanced CNC technology with unparalleled expertise to meet the rigorous demands of aerospace manufacturing. Whether you need custom CNC parts or large-scale production, our commitment to quality and efficiency ensures your success.

Contact CNCRUSH today for tailored CNC machining solutions that empower your aerospace projects to soar.