CNC Machining is revolutionizing the aerospace industry by offering unmatched precision, efficiency, and innovation. In today’s competitive aerospace manufacturing landscape, technologies like CNC machining service, CNC Milled parts, and CNC Turned parts are pivotal in achieving complex designs and stringent quality standards. This article draws on insights and content from leading industry sources—such as 3DS, GN Corporations, Sybridge, HLH Rapid, RCO Engineering, RapidDirect, Baker Industries, Robinson Tool, and Fictiv—to provide a comprehensive analysis. We also integrate perspectives from our own experience at CNCRUSH, a China-based expert with 12 years of experience in high-quality CNC machining services, specializing in CNC Milled parts and CNC Turned parts.

In the following sections, we discuss ten essential topics that explore the profound impact of CNC machining on the aerospace sector. Each section delves into technical details, industry benefits, and how CNCRUSH is ideally positioned as your partner in aerospace manufacturing excellence.

1. CNC Machining Service: Revolutionizing Aerospace Manufacturing

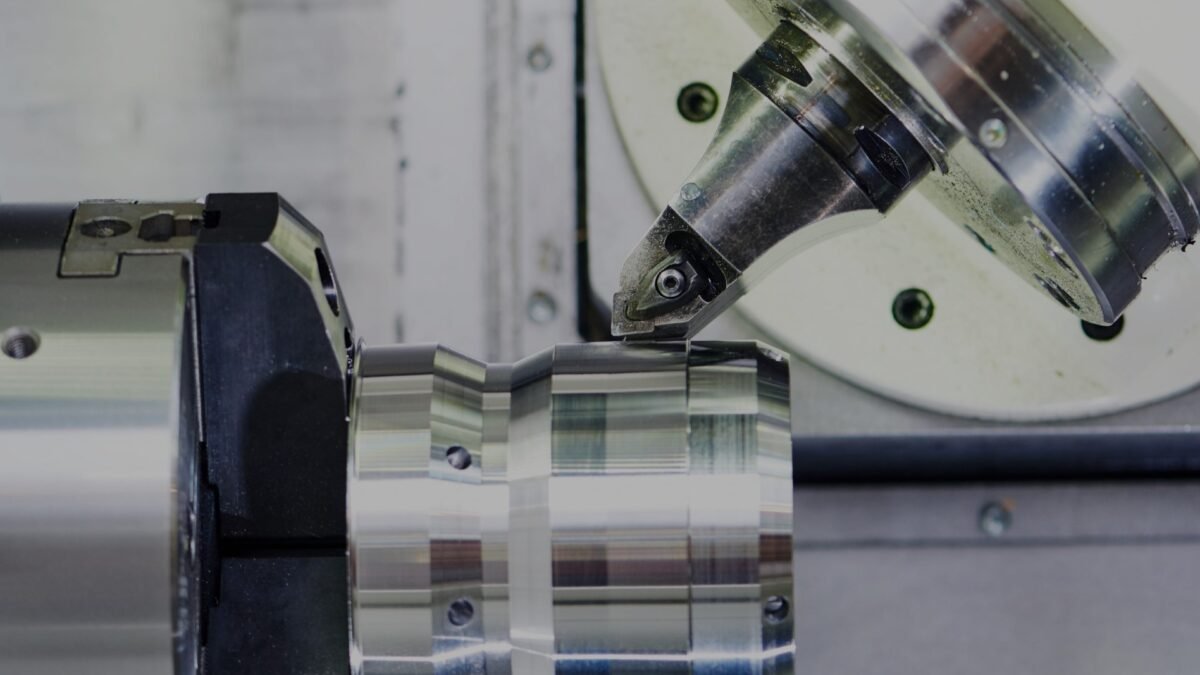

CNC Machining has become a cornerstone of aerospace manufacturing, streamlining production processes while upholding rigorous quality standards. In this section, we explore how modern CNC machining service techniques are enabling manufacturers to meet the demands of a high-precision industry.

Key Points:

- Automation and Precision: CNC machining service offers unparalleled accuracy through automated processes that minimize human error and ensure consistent quality.

- Reduced Lead Times: Automated production cycles enable faster turnaround times, critical in aerospace manufacturing where time is of the essence.

- Enhanced Quality Control: With integrated software and real-time monitoring, CNC machining ensures that every part meets exact specifications.

In-Depth Analysis:

The aerospace industry demands components that are not only lightweight and strong but also produced with exacting tolerances. CNC machining service plays a vital role here by eliminating variability, ensuring repeatable performance. For example, when manufacturing parts for aircraft engines or fuselage components, even a minor deviation could have significant safety and performance implications. The adoption of CNC machining allows manufacturers to adhere to strict aerospace standards while also catering to high-volume production.

At CNCRUSH, we have honed our CNC machining service over 12 years of dedicated practice. Our advanced technology, combined with skilled engineering, guarantees high-quality parts that meet the rigorous demands of aerospace manufacturing. Whether it’s CNC Milled parts or CNC Turned parts, our processes are designed to deliver consistency and precision.

2. CNC Milled Parts: Precision Engineering in Aerospace Applications

In aerospace manufacturing, CNC Machining is synonymous with precision—and nowhere is this more evident than in the production of CNC Milled parts. These components are fundamental to ensuring structural integrity and optimal performance in high-stress environments.

Key Points:

- Material Versatility: CNC Milled parts can be fabricated from a variety of materials, including aluminum, steel, and specialized alloys.

- Complex Geometries: Milling technology allows for the creation of intricate designs and complex shapes that are often required in aerospace components.

- High Tolerance Levels: The precision of CNC milling ensures that parts adhere to exact measurements, essential for maintaining performance standards in aerospace applications.

In-Depth Analysis:

The fabrication of CNC Milled parts involves the use of multi-axis milling machines that operate with exceptional precision. In aerospace, where parts often experience extreme operating conditions, the ability to produce components that consistently meet design specifications is invaluable. CNC machining enables the creation of parts that can withstand high stress and temperature variations, ensuring safety and reliability in aircraft structures.

Our facility at CNCRUSH specializes in delivering high-quality CNC Milled parts that satisfy even the most stringent aerospace requirements. Our engineers use state-of-the-art machinery and software to design and produce parts that excel in both performance and durability. This commitment to excellence has positioned us as a trusted provider of CNC machining services in China.

3. CNC Turned Parts: Enhancing Component Integrity in Aerospace Manufacturing

Complementing CNC Milled parts, CNC Turned parts are crucial for producing rotationally symmetric components that are common in aerospace designs. CNC Machining of these parts ensures that every element—from turbine blades to engine mounts—meets the highest standards of quality and performance.

Key Points:

- Efficiency in Production: CNC turning is ideal for producing cylindrical parts quickly and accurately.

- Surface Finish: Advanced turning techniques yield superior surface finishes, which are critical for both aesthetic and functional purposes in aerospace parts.

- Dimensional Accuracy: The tight tolerances achievable with CNC turning are essential for ensuring that parts fit together seamlessly in complex assemblies.

In-Depth Analysis:

The role of CNC Turned parts in aerospace manufacturing cannot be overstated. In many instances, these components are critical to the performance of aerospace systems. For example, engine components require exceptional surface finishes and precise dimensions to function correctly under high stress and temperature fluctuations. CNC turning provides a reliable method to produce these parts consistently.

At CNCRUSH, our focus on precision CNC machining is evident in our approach to producing CNC Turned parts. With 12 years of expertise, our China-based facility leverages cutting-edge technology to create parts that meet aerospace specifications, enhancing overall performance and reliability. Our commitment to quality makes us a preferred partner in the aerospace, automotive, and machine building sectors.

4. CNC Machining in Aerospace: Key Benefits and Innovations

CNC Machining is not only about precision—it’s also about innovation and efficiency. In this section, we explore the broader benefits of incorporating advanced CNC machining into aerospace manufacturing processes, and how it fuels continuous innovation in the industry.

Key Points:

- Customization: CNC machining allows for the rapid prototyping and production of custom parts, meeting unique aerospace requirements.

- Cost-Effectiveness: Automated processes reduce labor costs and material waste, making CNC machining a cost-effective solution.

- Integration with Digital Technologies: The integration of CAD/CAM software with CNC machines enables real-time design modifications, reducing development cycles.

In-Depth Analysis:

Aerospace manufacturing requires constant innovation to keep up with evolving technologies and market demands. CNC machining provides the flexibility to innovate quickly, allowing engineers to modify designs in real time based on testing and feedback. This integration of digital tools not only accelerates production but also improves the overall quality of aerospace components.

Innovative CNC machining techniques have led to significant breakthroughs in the aerospace sector. For instance, the development of lightweight yet robust materials, combined with precision machining, has enabled the production of components that enhance fuel efficiency and performance in aircraft. These advances are critical for meeting both environmental standards and market demands.

CNCRUSH remains at the forefront of this innovation. By combining years of expertise with the latest CNC machining technologies, we continue to offer cutting-edge solutions that drive the aerospace industry forward. Our commitment to delivering custom CNC solutions sets us apart as leaders in precision manufacturing.

5. CNC Machining Service: Accelerating Production Efficiency in Aerospace

Efficiency is key in aerospace manufacturing, and CNC Machining plays a central role in optimizing production cycles. This section examines how CNC machining service minimizes production times and maximizes output without compromising quality.

Key Points:

- Streamlined Workflows: Automated CNC processes reduce the need for manual intervention, speeding up production.

- Consistent Quality: Automation leads to repeatable processes, ensuring every part meets the same high standards.

- Scalability: CNC machining can be scaled to accommodate both low-volume prototypes and high-volume production runs.

In-Depth Analysis:

In aerospace manufacturing, delays can be costly—not only in terms of time but also in the risk of compromising component integrity. CNC machining service provides an effective solution by streamlining workflows and reducing cycle times. The automation inherent in CNC machining reduces variability and allows for rapid scaling of production, which is particularly beneficial when handling complex aerospace designs.

CNCRUSH leverages advanced CNC machining service to deliver projects on time, every time. Our state-of-the-art facility in China is designed for both precision and speed, ensuring that every aerospace component we produce adheres to the highest standards of quality and efficiency. By reducing lead times and production costs, our services provide a significant competitive advantage for aerospace manufacturers worldwide.

6. CNC Milled Parts: Ensuring Structural Integrity in Aerospace Components

The production of CNC Milled parts is vital for maintaining the structural integrity of aerospace systems. CNC Machining methods in milling guarantee that each component is produced with the highest level of precision and durability.

Key Points:

- Robust Material Processing: CNC Milled parts can be crafted from a range of high-performance materials to withstand extreme conditions.

- Enhanced Strength-to-Weight Ratios: Precision milling allows for the optimization of parts, contributing to lighter and stronger aerospace structures.

- Customization: Milling machines can produce intricate parts tailored to specific aerospace applications.

In-Depth Analysis:

In aerospace, every component must perform flawlessly under rigorous operating conditions. CNC Milled parts are engineered to provide exceptional strength while maintaining minimal weight—a critical factor in aircraft performance and fuel efficiency. The process of CNC milling ensures that every cut and contour of a part is meticulously controlled, resulting in components that are not only robust but also precisely designed.

At CNCRUSH, our commitment to quality is reflected in our ability to produce superior CNC Milled parts. Our facility employs cutting-edge machinery and rigorous quality controls to ensure that each component meets the demanding standards of the aerospace industry. Whether you require parts for automotive, machine building, or automotion applications, our CNC machining services deliver the performance you need.

7. CNC Turned Parts in Aerospace: Advancing Automotive, Machine Building, and Automotion

CNC Machining through turning processes is equally essential in aerospace manufacturing. CNC Turned parts are integral in creating components that require rotational symmetry and precision, which are also critical in automotive and machine building applications.

Key Points:

- High-Speed Production: CNC turning is optimized for speed, making it ideal for producing components in high volumes.

- Precision Cylindrical Parts: The turning process delivers exceptional accuracy, producing parts that are uniform and reliable.

- Versatility: CNC Turned parts are used in a variety of applications—from engine components in aerospace to precision parts in automotive and machine building.

In-Depth Analysis:

The turning process in CNC machining is uniquely suited to creating parts with precise diameters and consistent dimensions. In aerospace, these parts must adhere to strict tolerances, as even minor deviations can impact overall system performance. Additionally, the benefits of CNC turning extend to automotive and machine building sectors, where precision is paramount.

CNCRUSH’s expertise in CNC Turned parts is backed by 12 years of industry experience. Our China-based facility is equipped with the latest turning technology to ensure every component is produced with the utmost accuracy. By offering high-quality CNC machining services across multiple industries, we help our clients achieve excellence in design and performance.

8. CNC Machining in Aerospace and Defense: Integrating High-Tech Manufacturing with National Security

CNC Machining plays a dual role in both commercial aerospace and defense manufacturing. This section highlights how advanced CNC machining service is critical in producing components that meet stringent defense standards while driving commercial innovation.

Key Points:

- Dual-Use Technologies: Aerospace components often serve both commercial and defense applications, requiring high precision and reliability.

- Strict Compliance: CNC machining processes ensure that parts meet the rigorous standards set by aerospace and defense regulatory bodies.

- Enhanced Security: High-quality manufacturing processes contribute to the overall security and reliability of defense systems.

In-Depth Analysis:

The aerospace and defense industries share many overlapping requirements, including the need for components that can withstand extreme conditions. CNC machining provides the versatility needed to produce parts for both sectors. In defense, where the margin for error is exceptionally low, the precision and consistency of CNC machining are critical. Advanced techniques such as CNC milling and turning are employed to create parts that not only meet performance requirements but also contribute to national security.

At CNCRUSH, we understand the unique demands of both aerospace and defense. With over a decade of experience, our CNC machining service is engineered to deliver parts that satisfy the highest quality standards. Our commitment to precision manufacturing reinforces our position as a trusted partner in the aerospace, automotive, machine building, and automotion sectors.

9. Future Trends in CNC Machining for Aerospace Manufacturing

As technology evolves, the role of CNC Machining in aerospace manufacturing is set to become even more significant. In this section, we explore future trends and innovations that are expected to drive the industry forward.

Key Points:

- Digital Integration: The fusion of CNC machining with digital manufacturing (Industry 4.0) is paving the way for smarter, more connected production lines.

- Advanced Materials: Research into new, high-performance materials continues to expand the capabilities of CNC machining, allowing for lighter and stronger aerospace components.

- Sustainable Manufacturing: The focus on reducing waste and energy consumption is driving innovations in CNC machining processes, making them more environmentally friendly.

In-Depth Analysis:

Looking ahead, the aerospace industry is poised for dramatic transformations driven by technological advancements in CNC machining. Innovations such as real-time process monitoring, predictive maintenance, and artificial intelligence integration are set to enhance production efficiency and component quality. These trends not only promise to boost productivity but also contribute to safer and more sustainable manufacturing practices.

CNCRUSH is committed to staying at the forefront of these advancements. Our ongoing investment in digital integration and sustainable practices ensures that we continue to deliver high-quality CNC machining services that meet the evolving demands of the aerospace industry. With our expertise in CNC Milled parts and CNC Turned parts, we are well-equipped to tackle the challenges of tomorrow.

10. Why Choose CNCRUSH for Your CNC Machining Service Needs in Aerospace Manufacturing

When it comes to high-precision aerospace manufacturing, choosing the right partner is critical. CNC Machining is a complex and highly specialized field, and CNCRUSH stands out as a leader in this industry. In this final section, we outline the key reasons why CNCRUSH should be your go-to provider for CNC machining service.

Key Points:

- 12 Years of Expertise: With over 12 years in the industry, CNCRUSH offers unparalleled experience in high-quality CNC machining.

- Comprehensive Solutions: From CNC Milled parts to CNC Turned parts, we provide custom CNC solutions tailored to the aerospace sector.

- State-of-the-Art Facility: Our modern, China-based manufacturing plant is equipped with advanced CNC machinery, ensuring precision and reliability.

- Commitment to Quality: We adhere to stringent quality standards, ensuring every part we produce meets the rigorous demands of aerospace manufacturing.

- Diverse Industry Experience: Our services extend beyond aerospace to include automotive, machine building, and automotion, making us a versatile partner for various high-tech manufacturing needs.

In-Depth Analysis:

At CNCRUSH, we combine technical expertise with a deep understanding of the aerospace industry’s challenges. Our focus on precision CNC machining—whether through CNC Milled parts or CNC Turned parts—ensures that every component we produce is of the highest quality. We invite you to explore our services at CNCRUSH and discover how our tailored CNC manufacturing service can elevate your manufacturing processes.

Our commitment to continuous improvement and innovation makes us a trusted partner for clients around the world. By choosing CNCRUSH, you are partnering with a team that is dedicated to excellence, precision, and customer satisfaction in every aspect of CNC machining.

Table Analysis 1: Material Considerations in Aerospace CNC Machining

| Material Type | Key Properties | Typical Aerospace Applications | CNC Machining Considerations |

|---|---|---|---|

| Aluminum | Lightweight, high strength-to-weight ratio | Aircraft structures, fuselage components | Requires precise CNC Milled parts for optimal performance |

| Steel | High durability, excellent tensile strength | Engine components, structural frameworks | CNC Turned parts ensure tight tolerances and durability |

| Titanium | Exceptional strength, corrosion resistance | Engine parts, fasteners | Demands specialized CNC machining service for accuracy |

| Brass | Good machinability, low friction | Precision instruments, fittings | CNC Machined parts need careful finishing for aerospace use |

| Plastics | Lightweight, corrosion resistant | Non-structural components, interior fittings | CNC machining must balance material properties and design needs |

This table illustrates the varied material properties and corresponding CNC machining considerations that are crucial in the aerospace sector.

Table Analysis 2: Key Benefits of CNC manufacturing in Aerospace Manufacturing

| Benefit | Description | Impact on Aerospace Manufacturing |

|---|---|---|

| Enhanced Precision | Automated processes ensure components meet strict tolerances | Increases safety and performance in critical aerospace applications |

| Reduced Production Time | Automation and optimized workflows decrease lead times | Accelerates time-to-market for new aerospace designs |

| Customization & Flexibility | CNC machining can handle complex geometries and custom designs | Enables innovation and rapid prototyping for aerospace systems |

| Cost-Effectiveness | Minimizes material waste and labor costs | Improves overall profitability and competitiveness |

| Improved Quality Consistency | High repeatability in production | Ensures reliable performance of aerospace components |

This table compares the core benefits of adopting CNC machining, underscoring its impact on the aerospace industry.

Frequently Asked Questions (FAQ)

Q1: What is the role of CNC Machining in aerospace manufacturing?

A: CNC Machining plays a pivotal role in aerospace manufacturing by ensuring that components meet stringent quality and precision standards. It enables the production of both CNC Milled parts and CNC Turned parts that are essential for the structural integrity and performance of aerospace systems.

Q2: How does CNCRUSH differentiate itself in the CNC machining service industry?

A: CNCRUSH is a trusted CNC machining service provider with 12 years of experience. Based in China, we specialize in precision CNC Milled parts and CNC Turned parts. Our state-of-the-art facility, skilled engineers, and commitment to quality have made us a leading partner for aerospace, automotive, machine building, and automotion applications.

Q3: What materials can be processed using your CNC machining services?

A: Our CNC machining services cover a wide range of materials, including aluminum, steel, titanium, brass, and plastics. Each material is processed with tailored techniques to meet the specific requirements of aerospace components.

Q4: How do CNC Milled parts and CNC Turned parts differ?

A: CNC Milled parts are typically produced using multi-axis milling machines that handle complex, flat, or contoured designs. CNC Turned parts, on the other hand, are created using lathes that excel at producing rotationally symmetric components. Both methods ensure high precision and are essential for various aerospace applications.

Q5: What industries benefit from your CNC machining services?

A: In addition to aerospace, our CNC machining services benefit industries such as automotive, machine building, and automotion. Our ability to deliver high-quality CNC machining for metal and plastic parts makes us a versatile partner across multiple sectors.

Conclusion

CNC Machining is undoubtedly at the heart of modern high-precision aerospace manufacturing. From ensuring the flawless production of CNC Milled parts to the efficient creation of CNC Turned parts, advanced machining techniques are driving innovation and reliability in the aerospace, automotive, machine building, and automotion sectors. With a focus on precision, efficiency, and technological integration, CNC manufacturing service not only meets but exceeds the demanding standards of aerospace manufacturing.

Our deep-dive analysis reveals that CNC machining’s automated processes, material versatility, and integration with digital design tools are key factors in its success. As the aerospace industry continues to evolve with advancements in technology and material science, the role of CNC manufacturing will only become more critical.

At CNCRUSH, we take pride in our 12-year legacy of providing superior CNC machining services. Our commitment to excellence, precision, and customer satisfaction positions us as a premier China CNC factory for high-quality CNC Milled parts and CNC Turned parts. We invite you to visit our website at CNCRUSH to explore our comprehensive CNC manufacturing services and learn how we can support your next aerospace project.

By understanding these 10 incredible insights into CNC machining in aerospace manufacturing, you gain a holistic view of how precision engineering, technological innovation, and dedicated service providers like CNCRUSH are shaping the future of high-precision production. The future of aerospace manufacturing is here—and it’s powered by cutting-edge CNC manufacturing.