In modern manufacturing, CNC machining plays a crucial role, particularly in high-volume manufacturing. Its ability to deliver precision, speed, and scalability has transformed industries like automotive, machine building, and automation. High-volume CNC machining enables manufacturers to produce thousands or even millions of parts with exacting accuracy, making it an indispensable tool for businesses looking to compete in the global market.

At CNCRUSH, with 12 years of experience providing CNC machining services, we specialize in CNC milled parts and CNC turned parts, helping businesses scale their production while maintaining superior quality. Whether you’re producing components for automotive systems or industrial machines, our expertise ensures that your high-volume production needs are met with precision and efficiency.

1. What is High-Volume CNC Machining?

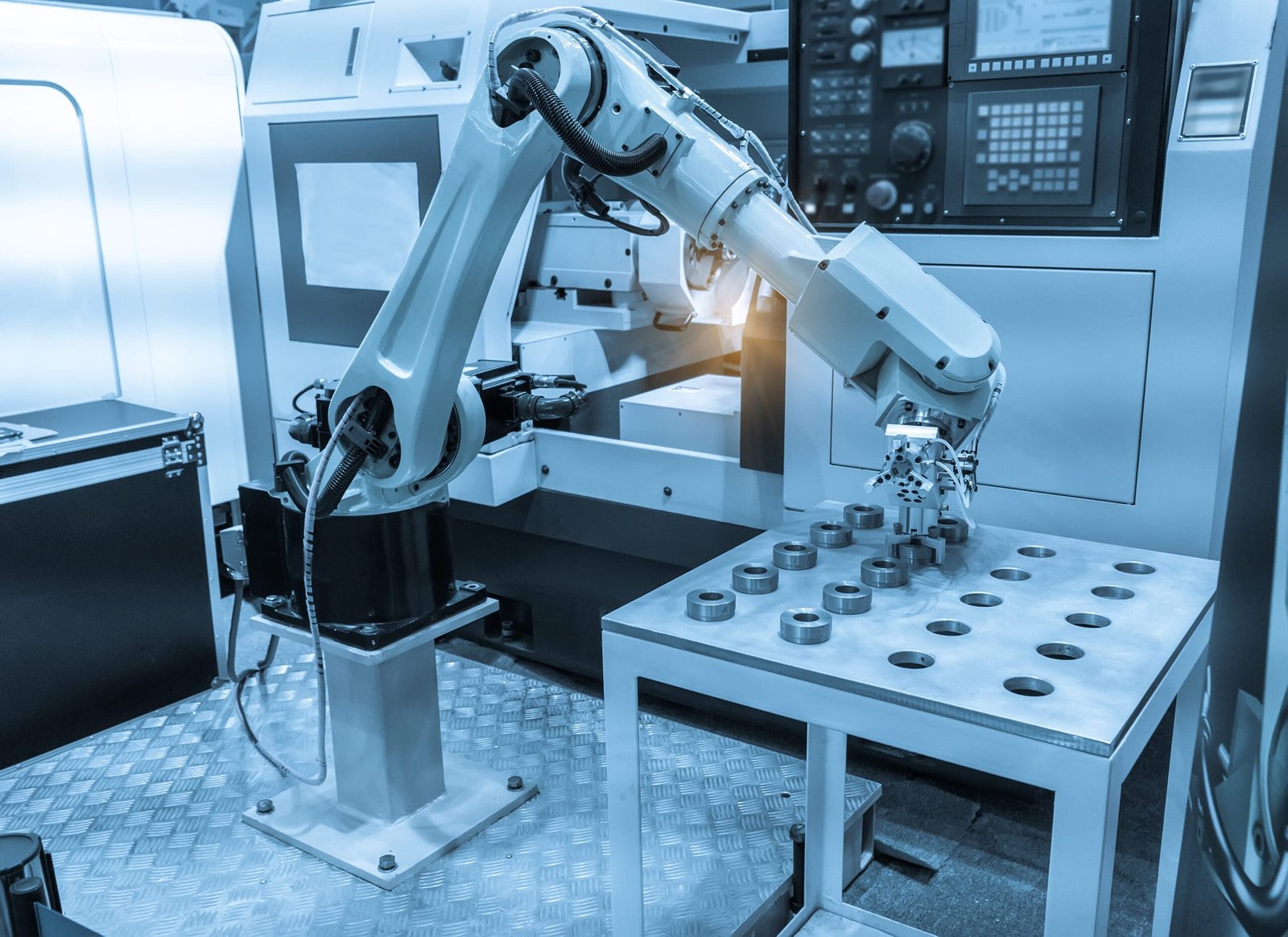

High-volume CNC machining refers to the mass production of components using computer numerical control (CNC) machines, allowing for consistent, repeatable processes across large production runs. This process is ideal for producing parts in large quantities while maintaining tight tolerances and high-quality standards. By leveraging automation and precision programming, CNC machining can produce hundreds to millions of parts with minimal human intervention, leading to improved efficiency and lower production costs.

For industries like automotive and automation, where precision and consistency are critical, high-volume CNC machining ensures reliable results every time.

2. The Benefits of CNC Machining in High-Volume Manufacturing

The advantages of high-volume CNC machining are vast, and they impact various aspects of production. Key benefits include:

- Increased Efficiency: CNC machining allows for faster production cycles, reducing lead times and speeding up time-to-market.

- Cost Reduction: By minimizing human labor and optimizing material usage, CNC machining lowers production costs, especially in large-scale operations.

- Precision and Accuracy: CNC machines can achieve extremely tight tolerances, which is essential for industries like automotive and machine building where precision is paramount.

- Scalability: Whether you need to produce hundreds or millions of parts, CNC machining scales effortlessly, maintaining quality across all production levels.

At CNCRUSH, we focus on maximizing these benefits for our clients, offering cost-effective, high-precision CNC machining services for high-volume production.

3. Low-Volume vs. High-Volume Manufacturing

In CNC machining, there are distinct differences between low-volume and High-Volume Manufacturing:

- Low-Volume CNC Machining: Typically used for prototype development or small production runs (50–1,000 parts), low-volume machining is ideal for companies that need flexibility in design or require parts with short lifecycles.

- High-Volume Manufacturing: Designed for mass production (1,000+ parts), high-volume machining focuses on reducing costs and improving efficiency through automation and optimized processes.

For businesses looking to bridge the gap between prototypes and full-scale production, both low and high-volume CNC machining have their roles, with CNCRUSH offering solutions tailored to your specific needs.

4. The Role of Automation in High-Volume Manufacturing

Automation is a key component of high-volume CNC machining. By automating the tool paths, material handling, and quality checks, manufacturers can drastically reduce downtime and increase production throughput. CNC machines are capable of running 24/7 with minimal human intervention, leading to higher productivity and fewer errors.

For CNC milled parts and CNC turned parts, automation ensures consistency in output, helping manufacturers meet tight deadlines without sacrificing quality.

5. Optimizing CNC Machining for Material Efficiency

One of the standout benefits of CNC machining in high-volume production is its ability to minimize material waste. Advanced CAD/CAM software allows for precise toolpath programming, optimizing material usage and reducing scrap. This not only lowers production costs but also supports sustainability efforts by conserving resources.

At CNCRUSH, we employ cutting-edge software to ensure that our CNC machining services are as efficient as possible, minimizing waste while delivering high-quality parts for industries like automotive and automation.

6. Achieving Superior Quality Control in High-Volume Manufacturing

Quality control is essential in high-volume CNC machining, particularly when producing parts for industries with stringent standards like automotive and machine building. CNC machines are equipped with sensors and real-time monitoring systems that allow for continuous quality checks during the production process. This ensures that each part meets the required specifications without the need for manual inspection.

For our clients at CNCRUSH, this level of quality control guarantees that every part we produce meets the highest standards, no matter the volume.

7. The Importance of Lead Time in High-Volume Manufacturing

In high-volume CNC production, lead time is a critical factor. Manufacturers must strike a balance between speed and quality to meet production deadlines. CNC machines excel in this regard, as they can produce large quantities of parts quickly without compromising precision.

CNCRUSH focuses on optimizing lead times for our clients, ensuring that their CNC milled parts and CNC turned parts are delivered on time, even in high-volume production runs.

8. CNC Machining for Automotive and Machine Building Industries

The automotive and machine building industries rely heavily on high-volume CNC machining for components such as engine blocks, gears, and precision shafts. These parts require tight tolerances and consistent quality, making CNC machining the go-to solution for manufacturers in these sectors.

At CNCRUSH, we specialize in providing high-precision CNC machining services for the automotive and machine building industries, delivering components that meet exacting standards.

9. Reducing Costs with High-Volume Manufacturing

One of the primary reasons manufacturers opt for high-volume CNC machining is its cost-efficiency. By automating processes and reducing the need for manual labor, CNC machining lowers operational costs. Additionally, the ability to minimize material waste and optimize tool usage further contributes to cost savings.

For businesses looking to reduce costs while maintaining high production standards, CNCRUSH offers affordable, high-quality CNC machining solutions.

10. The Future of High-Volume Manufacturing

As technology continues to advance, the future of high-volume CNC machining looks promising. Innovations in AI and machine learning are expected to further optimize CNC processes, reducing lead times and improving accuracy even further. For manufacturers, this means even greater opportunities for cost savings and efficiency gains.

At CNCRUSH, we stay at the forefront of CNC machining technology, ensuring that our clients benefit from the latest advancements in high-volume production.

FAQ Section

Q1: What is the typical lead time for High-Volume Manufacturing?

Lead times vary depending on the complexity of the part and the volume required. At CNCRUSH, we work to optimize lead times while ensuring that quality is never compromised.

Q2: How does high-volume CNC machining reduce costs?

By automating processes and minimizing material waste, high-volume CNC machining significantly lowers labor and production costs, making it an economical option for mass production.

Q3: What industries benefit most from High-Volume Manufacturing?

Industries such as automotive, machine building, and automation benefit greatly from high-volume CNC machining due to the precision and consistency it offers at scale.

In conclusion, CNC machining plays a vital role in high-volume manufacturing, offering precision, efficiency, and scalability for businesses in sectors like automotive, machine building, and automation. At CNCRUSH, we specialize in providing world-class CNC machining services to meet the demands of high-volume production, ensuring that our clients receive cost-effective, high-quality components every time.

For more information or to discuss your high-volume CNC machining needs, visit CNCRUSH.