As we navigate the ever-evolving landscape of CNC machining, 2024 promises to bring a plethora of innovations and trends that will significantly influence the industry. From advancements in technology to shifts in market demand, understanding these trends is crucial for manufacturers looking to remain competitive. At CNCRUSH, we specialize in high-quality CNC machining services, focusing on CNC Milled parts and CNC Turned parts, with over 12 years of experience in delivering precision-engineered solutions. This article delves into the top CNC machining trends of 2024, showcasing how they align with our commitment to excellence.

The CNC machining market is projected to experience substantial growth, driven by technological advancements, rising demand for automation, and the implementation of Industry 4.0 principles. With the CNC machinery market expected to grow at a CAGR of 5.6% from 2023 to 2032, businesses are increasingly investing in new technologies, such as AI-assisted machining and high-speed milling tools. These innovations enhance productivity, reduce lead times, and improve the quality of machined parts, making them essential for businesses aiming for operational excellence.

1. Growth of Smart Manufacturing

The integration of smart manufacturing technologies into CNC machining is reshaping the industry. By leveraging IoT (Internet of Things) devices, manufacturers can achieve real-time monitoring and predictive maintenance, which minimizes downtime and enhances operational efficiency. This trend is pivotal for companies like CNCRUSH, enabling us to offer our clients the reliability and precision they expect from our CNC machining services.

2. AI-Driven Machining Solutions

Artificial intelligence is making waves in CNC machining by streamlining the programming process and optimizing machining strategies. For instance, CloudNC’s CAM Assist now supports 3+2 axis CNC machines, significantly reducing the time needed for programming. Such advancements allow companies to respond swiftly to market demands and customize solutions for their clients, ensuring that services like CNC Milled parts and CNC Turned parts meet specific requirements.

3. Sustainability in CNC Machining

Sustainability is becoming a crucial focus in manufacturing. The adoption of eco-friendly materials and processes is on the rise, driven by both regulatory requirements and consumer demand for greener products. At CNCRUSH, we are committed to sustainable practices, ensuring that our CNC machining services are environmentally friendly while maintaining high precision and quality.

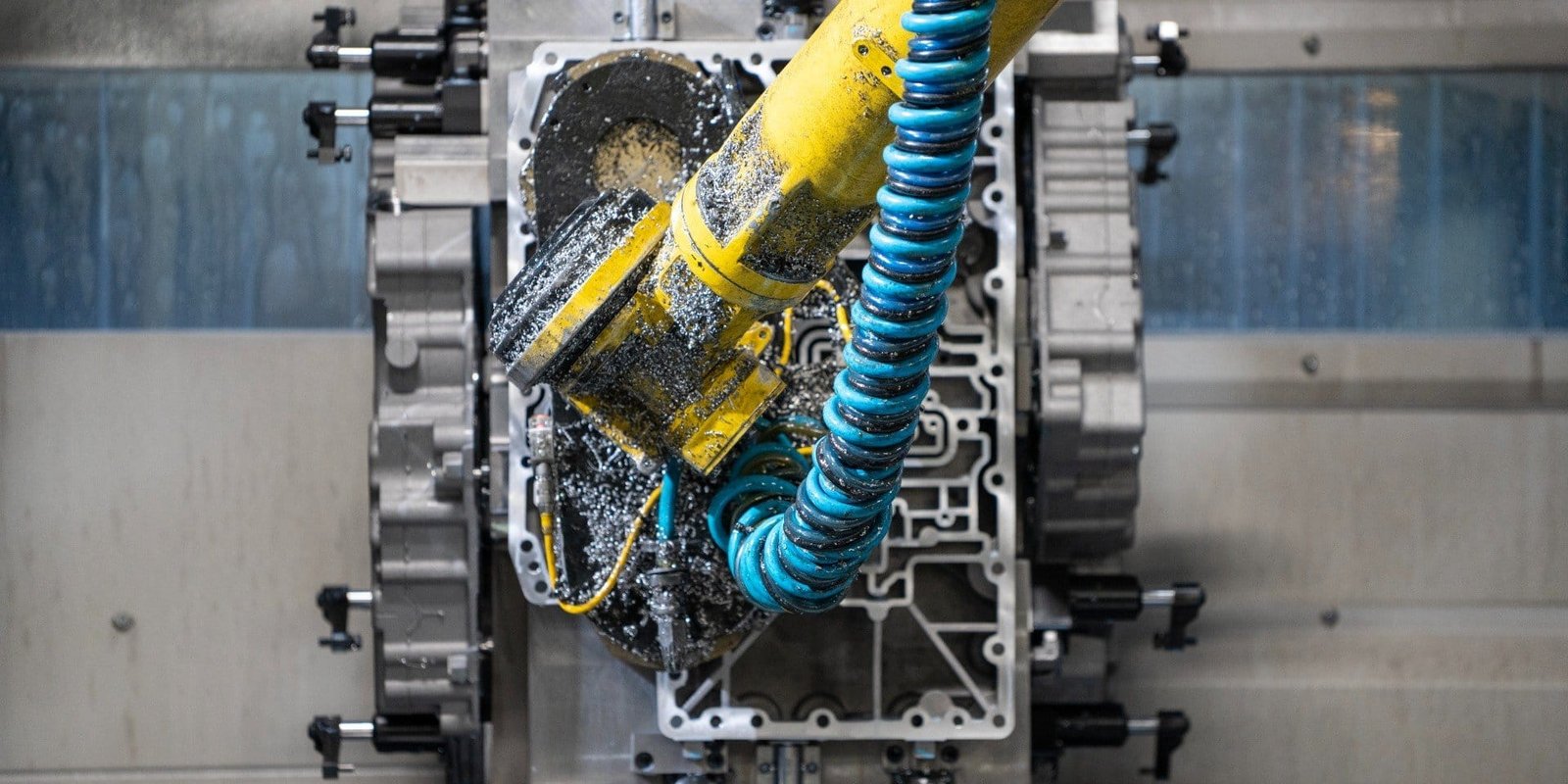

4. Advancements in CNC Technology

Technological innovations are transforming CNC machines, making them more versatile and efficient. New milling cutters, such as Mapal’s OptiMill-Alu-Wave, offer exceptional material removal rates, catering to industries like aerospace and automotive. By investing in state-of-the-art machinery, CNCRUSH can provide our clients with superior CNC Milled parts that meet stringent industry standards.

5. Rise of Micro-Machining

The trend towards micro-machining is gaining traction, especially for applications requiring high precision. Companies like Sunlight-Tech are pioneering micro-laser machining, allowing for the production of intricate components that traditional CNC methods struggle to achieve. This trend aligns with our commitment to high-quality CNC machining services, where precision is paramount.

6. Industry 4.0 Integration

The adoption of Industry 4.0 principles is leading to interconnected machines that enhance operational efficiency. Smart machine tools, equipped with automation systems, allow for seamless production workflows. At CNCRUSH, we are integrating these principles into our operations, ensuring that our CNC machining services are at the forefront of technological advancement.

7. Customization and Flexibility

As customer demands become more diverse, the need for customization in CNC machining is increasing. Manufacturers must be agile, capable of producing bespoke components swiftly. Our focus on providing tailored CNC Milled parts and CNC Turned parts allows us to meet the unique needs of our clients, enhancing satisfaction and loyalty.

8. Investment in Workforce Development

The complexity of modern CNC machining requires a skilled workforce. Companies are investing in training programs to equip their employees with the necessary skills to operate advanced machinery effectively. At CNCRUSH, we prioritize workforce development, ensuring our team is adept at handling the latest CNC technologies, thereby enhancing service delivery.

9. Enhanced Safety Protocols

With the rise of automation and advanced machinery, ensuring worker safety is more critical than ever. Manufacturers are implementing enhanced safety protocols and technologies to protect their workforce. At CNCRUSH, we prioritize safety in our operations, ensuring that our CNC machining services are not only efficient but also secure.

10. Expansion into New Markets

As the CNC machining industry grows, there are emerging opportunities in various sectors, including healthcare, aerospace, and renewable energy. Companies that adapt to these changes will thrive. At CNCRUSH, we are strategically positioning ourselves to cater to these expanding markets, ensuring our CNC machining services meet evolving industry needs.

Analysis of Market Trends

| Trend | Description | Implication for CNCRUSH |

|---|---|---|

| Smart Manufacturing | Adoption of IoT for real-time monitoring and maintenance | Enhanced reliability and operational efficiency |

| AI-Driven Solutions | Implementation of AI to optimize machining processes | Increased customization and responsiveness |

| Sustainability | Focus on eco-friendly practices and materials | Commitment to environmental responsibility |

| CNC Technology Advancements | Innovations in milling and turning tools | Improved product quality and precision |

| Micro-Machining | Growth in demand for highly precise micro-parts | Opportunities for niche market engagement |

| Industry 4.0 Integration | Interconnected machines for seamless operations | Streamlined production processes |

| Customization | Rising demand for bespoke components | Greater client satisfaction and retention |

| Workforce Development | Investment in training for advanced CNC operations | Skilled workforce leading to better service delivery |

| Enhanced Safety | Implementation of robust safety measures in machining | Safer working environment for employees |

| New Market Opportunities | Expansion into sectors like healthcare and renewable energy | Strategic growth in diversified markets |

FAQ Section

1. What is CNC machining?

CNC machining is a computer-controlled manufacturing process that uses precise tools to create parts and components from various materials.

2. What types of parts can CNCRUSH manufacture?

CNCRUSH specializes in CNC Milled parts and CNC Turned parts, providing high-precision machining services for various applications.

3. How does CNCRUSH ensure quality in its CNC machining services?

We employ stringent quality control measures and utilize advanced machinery to ensure that every part meets the highest industry standards.

4. Can CNCRUSH handle custom orders?

Yes, we pride ourselves on our ability to provide customized CNC machining solutions tailored to our clients’ specific needs.

5. What industries does CNCRUSH serve?

We cater to a diverse range of industries, including aerospace, automotive, and medical sectors.

Conclusion

The CNC machining industry is on the cusp of transformative change as we move into 2024. With advancements in technology, a focus on sustainability, and an increasing demand for customization, businesses must adapt to stay competitive. At CNCRUSH, we are committed to providing high-quality CNC machining services, specializing in CNC Milled parts and CNC Turned parts, and we invite you to explore our offerings to meet your manufacturing needs.

Służysz społeczności blogowej, pięknie przy tym składasz frazy, przyjmij najszczersze wdzięczności moich wyrazy 🙂