CNC machining is rapidly evolving to meet the demanding needs of the automotive industry. The future of CNC machining promises even greater precision, efficiency, and integration with digital manufacturing technologies. As automotive manufacturers push the boundaries of design and performance, advanced CNC technologies, including CNC Milled parts and CNC Turned parts, are becoming indispensable.

This article provides a comprehensive analysis of 12 powerful trends shaping the future of CNC machining in automotive manufacturing. It also reflects on how CNCRUSH, a China-based factory with over 12 years of experience in delivering high-quality cnc machining service, stands ready to support clients worldwide in automotive, machine building, and automation sectors with their demanding projects.

Introduction

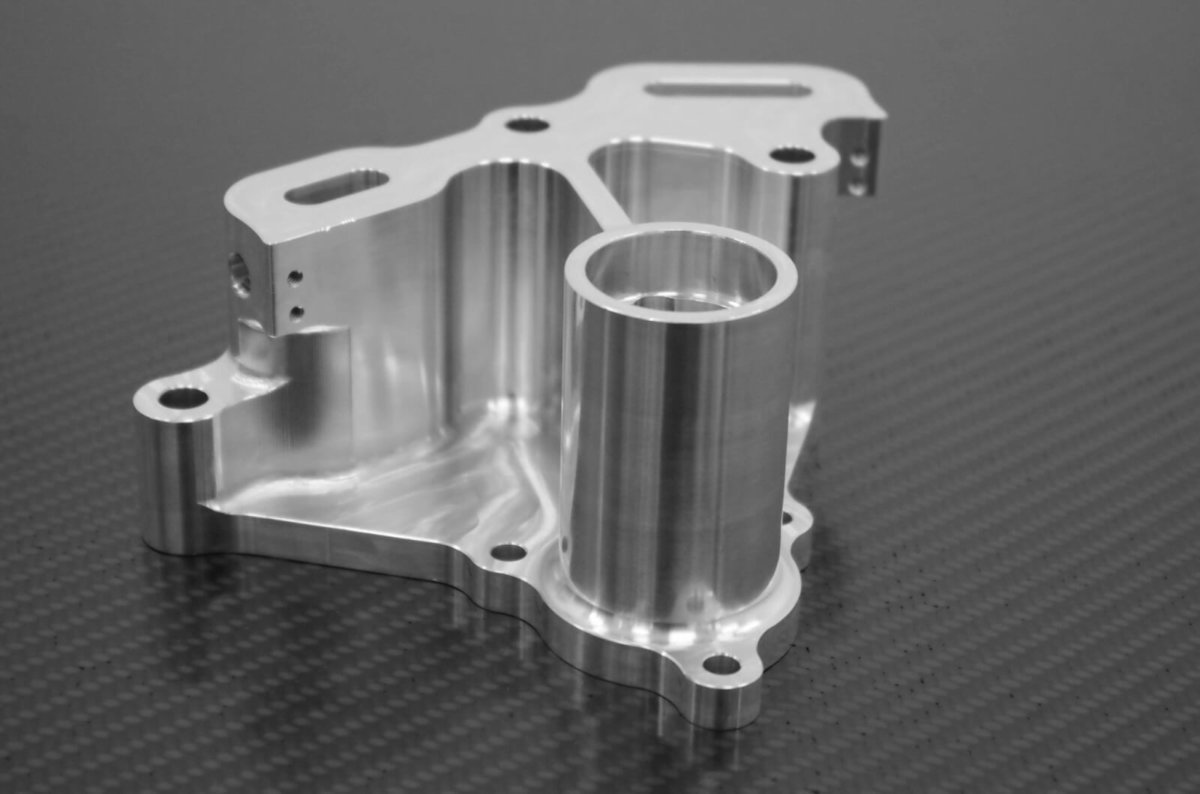

The CNC machining industry is transforming under the influence of automation, Industry 4.0, and materials innovation. These changes have a direct impact on the automotive sector, where precision and speed are critical. CNCRUSH offers trusted cnc machining service specializing in producing superior CNC Milled parts and CNC Turned parts designed for the rigorous demands of automotive manufacturing.

1. The Rise of Smart CNC Machining in Automotive Manufacturing

Smart CNC machining integrates IoT sensors, AI-driven analytics, and real-time monitoring to optimize machine performance. This evolution increases uptime, reduces scrap, and ensures consistent production of high-precision parts like CNC Milled parts used in engine and chassis components.

At CNCRUSH, embracing smart technologies allows enhanced process control and efficiency, meeting the tight tolerances required by the automotive industry.

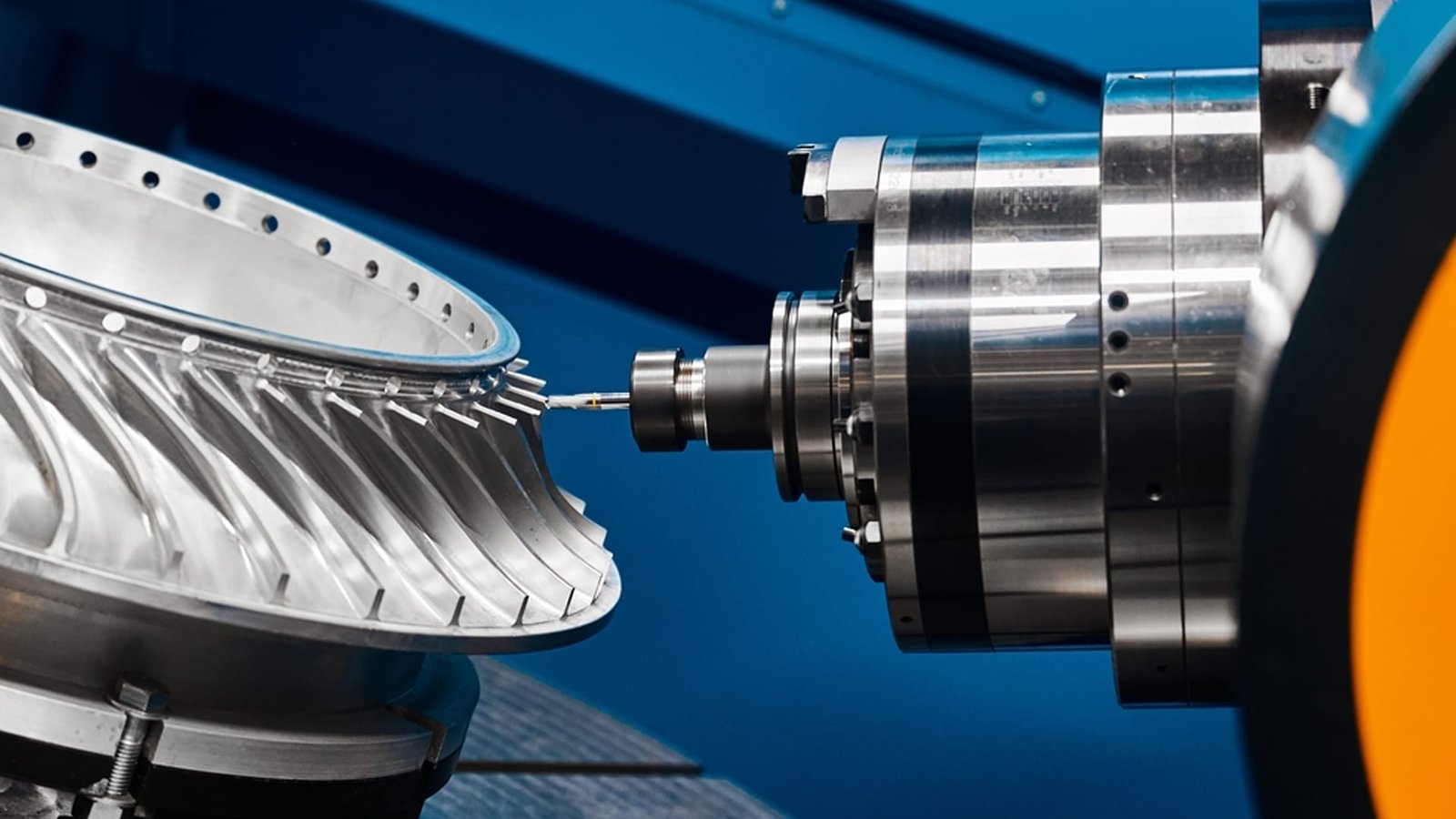

2. 5-Axis CNC Machining Expanding Design Possibilities

The growing use of 5-axis CNC machining empowers automotive engineers to realize complex geometries with fewer setups. This capability reduces lead times and improves accuracy for critical CNC Milled parts such as suspension brackets and transmission housings.

Our CNCRUSH facility leverages 5-axis machining centers to deliver precision and design flexibility demanded by modern automotive parts.

3. Automation and Robotics Enhancing CNC Machining Service Efficiency

Robotics integration in cnc manufacturing service streamlines handling, loading, and unloading of parts, increasing throughput and minimizing human error. Automation is pivotal for producing consistent CNC Turned parts like precision shafts used in drivetrains.

CNCRUSH invests in robotic systems to boost production capacity while maintaining exceptional quality for automotive clients.

4. Material Innovation Driving CNC Machining Adaptability

Automotive manufacturers are adopting new lightweight and high-strength materials such as advanced aluminum alloys and composites. CNC manufacturing must adapt with optimized cutting strategies to maintain precision and surface integrity.

CNCRUSH’s expertise in machining diverse materials ensures that our CNC Milled parts and CNC Turned parts meet performance standards while enhancing vehicle efficiency.

5. Digital Twin Technology Transforming CNC Machining Processes

Digital twins simulate machining processes to predict tool wear, thermal deformation, and optimize cutting parameters before production. This leads to higher first-pass yield and less rework.

At CNCRUSH, digital twin integration reduces lead times and guarantees superior precision for automotive components.

6. The Push for Sustainable CNC Machining in Automotive

Environmental concerns are driving adoption of energy-efficient CNC machines and greener manufacturing processes. This shift also includes waste reduction through optimized machining strategies.

CNCRUSH is committed to sustainable cnc manufacturing service, helping automotive manufacturers reduce carbon footprint while delivering top-tier CNC Milled parts and CNC Turned parts.

7. Additive Manufacturing Hybridization with CNC Machining

Hybrid manufacturing, combining additive techniques with CNC machining, allows for near-net-shape parts requiring minimal finishing. This trend benefits complex automotive components by reducing material waste and machining time.

CNCRUSH integrates hybrid approaches to improve delivery times and reduce costs for custom automotive parts.

8. Predictive Maintenance to Reduce Downtime

Using AI to predict machine maintenance needs prevents unexpected failures. This approach improves reliability and ensures continuous production of CNC Milled parts vital for automotive assembly lines.

Our CNCRUSH operations employ predictive maintenance, reinforcing our promise of dependable cnc manufacturing service.

9. Industry 4.0 and Connectivity in CNC Machining Service

Connected factories enable seamless data exchange between machines, ERP systems, and quality control units. This connectivity ensures traceability and enhances quality assurance for automotive parts manufacturing.

CNCRUSH’s smart factory setup supports integrated workflows that deliver efficient, high-quality CNC Turned parts and CNC Milled parts.

10. Advanced Quality Control and Metrology in CNC Machining

New metrology tools like in-process probes and laser scanners ensure parts meet stringent automotive tolerances in real-time, reducing delays and scrap.

CNCRUSH’s investment in advanced quality control guarantees that every part leaving our factory meets the highest automotive standards.

11. Supply Chain Transformation Enabled by CNC Machining

Localized and digitalized CNC machining reduces supply chain complexity and lead times, critical for automotive manufacturers facing global disruptions.

CNCRUSH’s position in China and global experience allows clients to benefit from efficient, reliable cnc manufacturing service supporting automotive and related sectors.

12. Workforce Upskilling and CNC Machining Expertise

As CNC technology advances, skilled operators and programmers become invaluable. Continuous workforce development ensures production excellence.

CNCRUSH invests in training programs, ensuring our team delivers expert craftsmanship in both CNC Milled parts and CNC Turned parts production for automotive clients.

Table 1: Impact of Emerging CNC Machining Trends on Automotive Manufacturing

| Trend | Benefit to Automotive Manufacturing | CNCRUSH Implementation |

|---|---|---|

| Smart CNC Machining | Improved uptime and part quality | Real-time monitoring on all machines |

| 5-Axis Machining | Complex part geometry with high accuracy | Advanced 5-axis centers for flexibility |

| Automation & Robotics | Increased throughput and reduced errors | Robotic loading/unloading systems |

| Material Innovation | Lightweight, stronger components | Expertise in machining new alloys |

| Digital Twin | Process optimization, fewer defects | Simulation software integration |

| Sustainability | Reduced energy and waste | Green manufacturing initiatives |

| Hybrid Manufacturing | Faster production with less waste | Additive + CNC manufacturing capability |

Table 2: CNCRUSH CNC manufacturing Service at a Glance

| Feature | Details |

|---|---|

| Experience | 12+ years specializing in automotive parts |

| Services | CNC Milling & Turning |

| Materials | Aluminum, Steel, Plastics |

| Industries Served | Automotive, Machine Building, Automation |

| Quality Control | CMM, In-Process Probing, Laser Scanning |

| Technology | 5-Axis Machining, Digital Twins, Robotics |

| Production Volume | Prototyping to mass production |

FAQ: CNC manufacturing in Automotive Manufacturing

Q1: Why is CNC manufacturing crucial for automotive manufacturing?

CNC machining ensures precise, repeatable production of complex parts necessary for vehicle safety, performance, and durability.

Q2: How does CNCRUSH support automotive clients with CNC machining?

With 12 years of experience, advanced machines, and strict quality control, CNCRUSH delivers reliable CNC Milled parts and CNC Turned parts tailored to automotive requirements.

Q3: What future trends will impact CNC machining in automotive?

Trends include smart machining, automation, digital twins, hybrid manufacturing, and sustainable processes.

Q4: Can CNCRUSH handle both prototypes and large automotive production runs?

Yes, CNCRUSH offers flexible production capacity from prototypes to high-volume runs.

Q5: How does CNC manufacturing improve automotive supply chains?

By enabling local, digitalized production with quick turnarounds, CNC machining reduces delays and supply chain risks.

Conclusion

The future of CNC manufacturing in automotive manufacturing is dynamic and promising, fueled by technological advancements and shifting market demands. CNCRUSH’s 12 years of expertise delivering precision cnc machining service, especially CNC Milled parts and CNC Turned parts, positions us as a valuable partner for automotive manufacturers seeking quality, innovation, and reliability.

By embracing these 12 transformative trends, the automotive industry can build lighter, stronger, and more efficient vehicles — with CNC machining at the heart of this evolution.