Precision Manufacturing has become the lifeblood of modern industries, driving innovation across sectors like aerospace, automotive, and machine building. At the forefront of this revolution is CNC machining, a technology reshaping the way components are designed and produced. With 12 years of expertise, CNCRUSH, a leading China CNC factory, is empowering businesses worldwide with CNC machining services that deliver superior CNC Milled parts and CNC Turned parts at an affordable price point.This article explores the transformative impact of CNC machining on Precision Manufacturing, delving into emerging trends, benefits, and real-world applications. If you’re seeking reliable solutions for high-quality CNC milling and turning, CNCRUSH is your trusted partner for custom CNC machining needs.

Table of Contents

- The Evolution of CNC Machining in Precision Manufacturing

- Why CNC Machining Leads the Future of Precision Manufacturing

- Benefits of CNC Machining for Modern Industries

- Top CNC Machining Trends to Watch in 2024

- Innovative Applications of CNC Machining

- Challenges Facing CNC Machining in Precision Manufacturing

- Why China is Leading the CNC Machining Revolution

- How CNCRUSH is Shaping the Future of CNC Machining

- CNC Machining for the Automotive and Automation Sectors

- FAQ: CNC Machining in Precision Manufacturing

The Evolution of CNC Machining in Precision Manufacturing

CNC machining has transformed from a niche technology to a global standard for manufacturing high-precision components. Initially developed for simplified repetitive tasks, modern CNC systems now incorporate AI, automation, and advanced materials processing.

Key milestones include:

- The 1980s: Introduction of multi-axis CNC systems enabling complex geometries.

- The 2000s: Integration of CAD/CAM software for seamless design-to-production workflows.

- Today: Industry 4.0 technologies, such as IoT-connected CNC machines, optimize efficiency and scalability.

At CNCRUSH, we continually evolve with these advancements, offering custom CNC solutions that leverage cutting-edge tools and techniques.

Why CNC Machining Leads the Future of Precision Manufacturing

Precision Manufacturing demands unparalleled accuracy, speed, and scalability. CNC machining outpaces traditional methods due to its ability to:

- Produce components with tight tolerances of ±0.001mm.

- Handle complex geometries with ease.

- Adapt to diverse materials, including aluminum, brass, and advanced composites.

Moreover, CNC machining supports sustainability by minimizing material waste—a key driver in industries striving for greener operations.

Benefits of CNC Machining for Modern Industries

| Benefit | Explanation | Example Application |

|---|---|---|

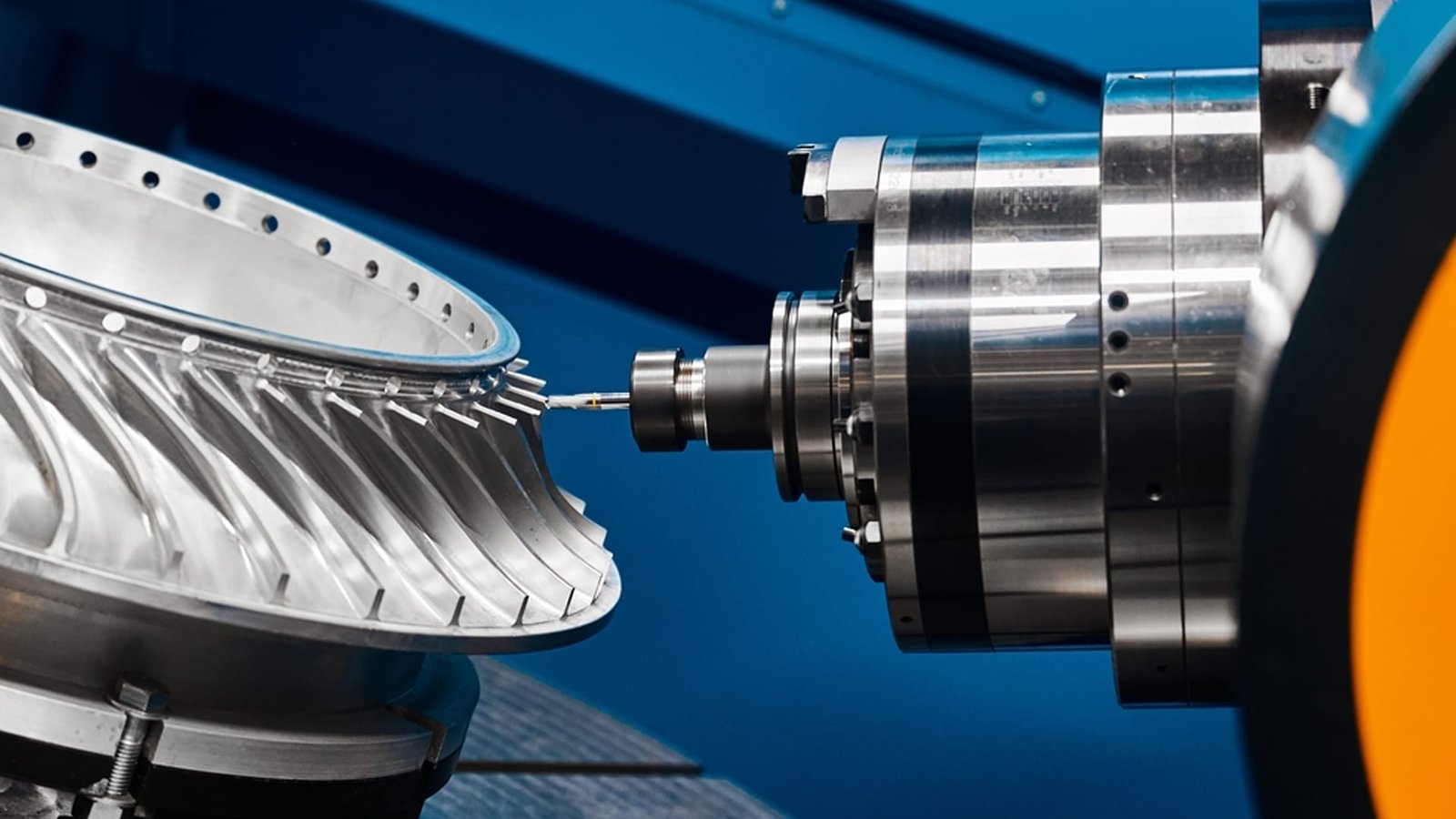

| Precision | Ensures consistent results across high-volume runs. | Aerospace turbine blades. |

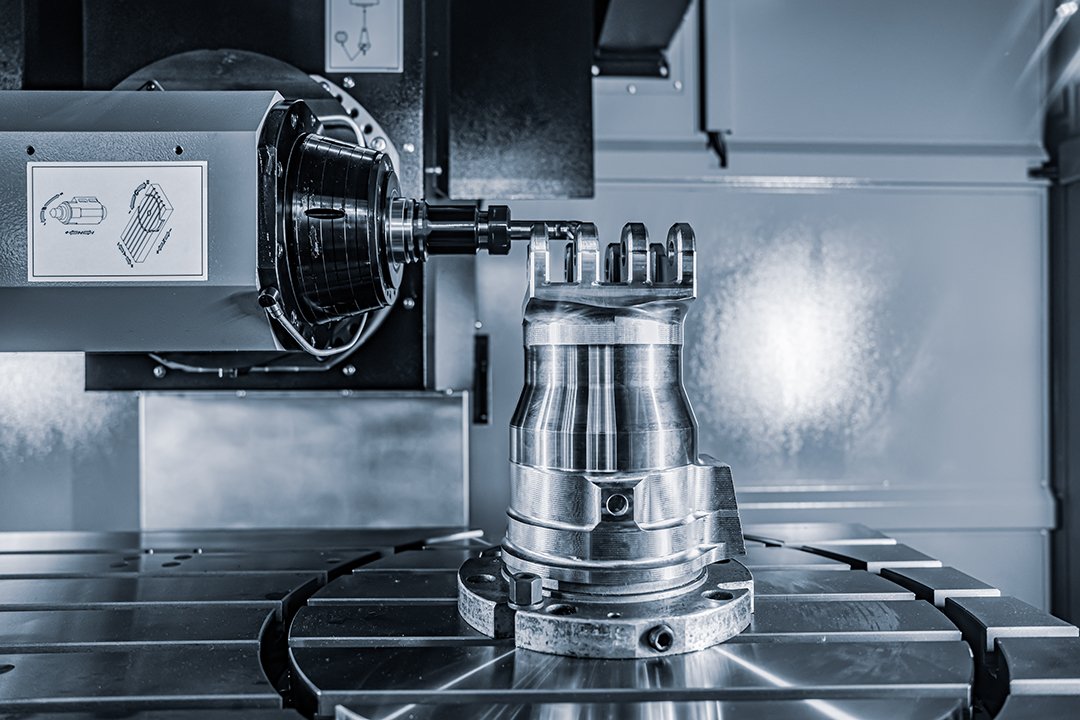

| Speed | Shortens production cycles for prototyping and scaling. | Automotive engine components. |

| Versatility | Works with metals, plastics, and composite materials. | Machine-building custom tools. |

| Cost-Effectiveness | Reduces waste and lowers labor costs. | Automation systems requiring mass production. |

| Scalability | Seamlessly transitions from prototypes to mass production. | Industrial robotics assemblies. |

Top CNC Machining Trends to Watch in 2024

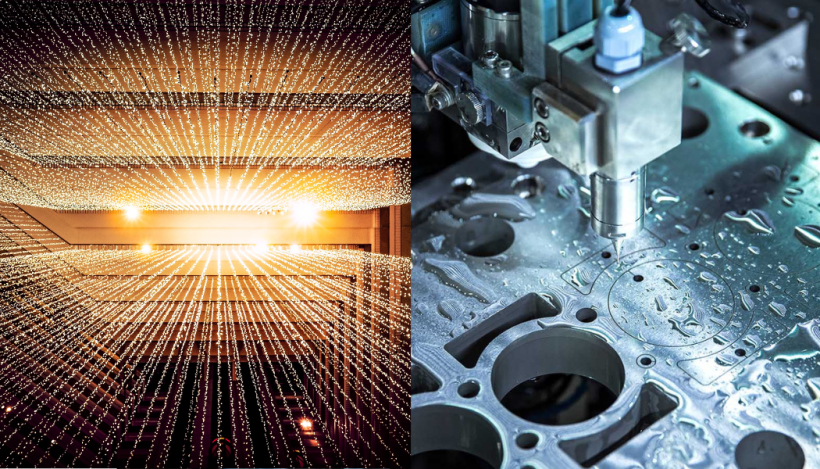

- AI-Driven Machining

Advanced AI algorithms optimize tool paths and improve efficiency, reducing machining times by up to 20%. - Hybrid Manufacturing

Combining CNC machining with additive manufacturing offers new possibilities for lightweight, intricate components. - Sustainability Initiatives

CNC systems are adopting energy-efficient designs and better waste management practices to reduce their environmental impact. - Smart Factories

IoT-enabled machines provide real-time analytics for predictive maintenance, minimizing downtime and costs.

Innovative Applications of CNC Machining

Industries are finding new ways to leverage CNC machining:

- Aerospace: High-precision components like engine housings and structural supports.

- Automotive: Custom parts for electric vehicles and performance engines.

- Medical: Titanium implants and surgical tools with micrometer-level accuracy.

- Automation: Components for robotic arms and smart manufacturing systems.

Challenges Facing CNC Machining in Precision Manufacturing

While CNC machining leads in Precision Manufacturing, it faces several challenges:

- Material Hardness: Machining high-strength alloys requires advanced tooling.

- Skill Shortages: The demand for CNC-trained professionals continues to rise.

- Cost Pressures: Balancing affordability with high-quality standards is essential.

CNCRUSH overcomes these challenges by investing in skilled engineers, modern equipment, and rigorous quality control processes.

Why China is Leading the CNC Machining Revolution

China’s dominance in the CNC machining industry is attributed to:

- State-of-the-Art Infrastructure: Factories equipped with advanced 5-axis CNC machines.

- Skilled Workforce: Engineers with decades of experience in precision manufacturing.

- Cost Efficiency: Competitive pricing due to streamlined supply chains.

At CNCRUSH, located in China, we exemplify these strengths, delivering world-class CNC machining services to clients across the globe.

How CNCRUSH is Shaping the Future of CNC Machining

For over 12 years, CNCRUSH has been at the forefront of Precision Manufacturing, specializing in CNC Milled parts and CNC Turned parts for industries including automotive, aerospace, and automation.

Our Commitment:

- Unmatched Precision: Tight tolerances and consistent quality.

- Affordable CNC Machining: Delivering cost-effective solutions without compromising quality.

- Custom CNC Solutions: Tailored services for complex projects.

CNC Machining for the Automotive and Automation Sectors

Previously, manufacturing companies only needed automation for high-volume CNC machining projects. In recent years, automation has evolved and become valuable for meeting various requirements. One use case is low-volume work that demands heavy lifting and repetitive actions. While manually carrying out these tasks may be strenuous, automated processes allow you to work at a faster pace and with greater flexibility.

And automation is only continuing to grow. Looking ahead, CNC machines will be able to handle even more complex processes, and operate with greater production speed and efficiency. More and more companies today are considering automation to be a wise investment and a cost-effective option for developing high-quality parts now and in the future.

The automotive and automation industries rely on CNC machining for:

- Prototyping: Custom parts for electric and hybrid vehicles.

- Production: Scalable manufacturing of gear systems and engine components.

- Automation Tools: High-precision parts for robotic systems and assembly lines.

By leveraging CNC machining, these industries enhance innovation while maintaining cost-efficiency.

FAQ: CNC Machining in Precision Manufacturing

Q: What is the main advantage of CNC machining in precision manufacturing?

A: CNC machining ensures high accuracy and repeatability, making it ideal for industries requiring tight tolerances.

Q: Why choose CNCRUSH for CNC machining services?

A: With 12+ years of experience and advanced facilities in China, CNCRUSH delivers affordable, high-quality CNC solutions.

Q: What industries benefit most from CNC machining?

A: Aerospace, automotive, medical, and automation industries rely heavily on CNC machining for their precision needs.

Final Thoughts

CNC machining is undeniably the future of Precision Manufacturing, offering unmatched versatility, speed, and scalability for modern industries. As a global leader in CNC machining services, CNCRUSH combines expertise, innovation, and affordability to help businesses achieve their manufacturing goals.

Explore how CNCRUSH can transform your manufacturing projects with high-quality CNC Milled parts and CNC Turned parts by visiting CNCRUSH today.