CNC milling and CNC turning are two of the most essential processes in modern manufacturing, each offering distinct advantages for creating parts with precise specifications. Understanding the key differences between these methods is crucial when deciding which process to use for producing CNC Milled parts or CNC Turned parts in industries such as automotive, machine building, and automation. Whether you’re a business seeking high-quality CNC machining services or an engineer looking to optimize your production process, knowing the specific strengths of these two techniques can save you both time and money.

At CNCRUSH, a professional CNC machining service provider based in China with over 12 years of experience, we specialize in both CNC milling and CNC turning. In this comprehensive guide, we’ll explore the differences between these two methods, discuss their applications, and explain how to choose the right technique for your project.

Table of Contents

- What is CNC Milling?

- What is CNC Turning?

- Key Differences Between CNC Milling and CNC Turning

- When to Use CNC Milling?

- When to Use CNC Turning?

- Applications in Automotive, Machine Building, and Automation

- Choosing Between CNC Milled and CNC Turned Parts for Your Project

- Advantages of Combining CNC Milling and CNC Turning

- How CNCRUSH Provides Expert CNC Machining Services

- FAQ: Frequently Asked Questions about CNC Milling and Turning

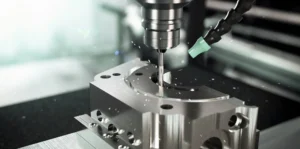

1. What is CNC Milling?

CNC milling is a subtractive manufacturing process where material is removed from a workpiece using rotary cutters. The workpiece is typically fixed on a table while the cutting tools move along various axes to remove material and shape the part. CNC milling is ideal for creating complex geometries and features such as slots, holes, pockets, and curves. This process can work with a variety of materials, including aluminum, steel, brass, and plastic.

At CNCRUSH, we utilize advanced CNC milling machines that offer high precision and flexibility for producing CNC Milled parts that meet stringent quality standards, especially in industries like automotive, machine building, and automation.

2. What is CNC Turning?

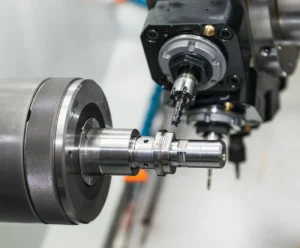

CNC turning is another subtractive process where the workpiece rotates on a spindle while a cutting tool removes material. Unlike milling, where the cutting tool rotates, turning involves the rotation of the workpiece itself. This process is ideal for producing cylindrical parts, such as shafts, rods, and threaded components.

CNC Turned parts are commonly used in automotive and machine building applications due to their high accuracy and efficiency in producing symmetrical features. At CNCRUSH, our CNC turning services deliver exceptional precision, even for complex geometries.

3. Key Differences Between CNC Milling and CNC Turning

The primary difference between CNC milling and CNC turning lies in the motion of the cutting tool and the workpiece:

- CNC Milling: The cutting tool rotates, while the workpiece remains stationary. This makes it suitable for parts that require intricate shapes and multi-dimensional features.

- CNC Turning: The workpiece rotates while the cutting tool remains stationary. This process is ideal for cylindrical parts and produces high precision with symmetrical features.

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Cutting Tool Movement | Rotating cutting tool, stationary workpiece | Rotating workpiece, stationary tool |

| Ideal Part Shape | Complex, multi-axis geometries | Cylindrical or symmetrical parts |

| Material Removal | Horizontal or vertical cutting | Lateral cutting along the workpiece |

| Surface Finish | Often requires finishing steps | Excellent finish due to continuous motion |

4. When to Use CNC Milling?

CNC milling is best suited for parts that require complex geometries, such as features with multiple angles, curves, and intricate surface details. The versatility of CNC milling allows for multi-axis movement, making it ideal for creating parts that cannot be produced through simple turning operations.

Applications where CNC milling is preferred include:

- Automotive components that require complex shapes, such as engine parts and suspension components.

- Machine building parts that have multiple mounting holes, slots, and intricate designs.

- Automation equipment, where precision parts with various features need to be integrated into larger systems.

5. When to Use CNC Turning?

CNC turning is the go-to process for producing cylindrical parts with high precision. Since the workpiece rotates, turning is ideal for creating round components with tight tolerances. Turning is typically faster than milling for cylindrical parts, making it the preferred choice for high-volume production of symmetrical parts.

Applications where CNC turning is preferred include:

- Shafts and rods used in automotive transmission systems.

- Threaded components required in machine building applications, such as screws and bolts.

- Automated systems that rely on precise cylindrical parts for moving mechanisms.

6. Applications in Automotive, Machine Building, and Automation

Both CNC milling and CNC turning play critical roles in industries such as automotive, machine building, and automation. Depending on the part’s geometry and functional requirements, one process may be more suitable than the other.

- Automotive: CNC milling is used for intricate engine components, while CNC turning produces shafts, pins, and fasteners.

- Machine Building: CNC Milled parts often include brackets, plates, and housings, while CNC Turned parts are used for bushings, rollers, and couplings.

- Automation: Many automated systems rely on CNC Turned parts for rotating mechanisms, while CNC Milled parts are used for support structures and control panels.

7. Choosing Between CNC Milled and CNC Turned Parts for Your Project

When deciding between CNC Milled parts and CNC Turned parts, it’s important to consider the geometry, complexity, and function of the part:

- Choose CNC Milling if your part requires intricate geometries, multi-axis movements, or features that involve multiple angles and curves.

- Choose CNC Turning if your part is primarily cylindrical or symmetrical and requires tight tolerances.

At CNCRUSH, we provide both CNC milling and CNC turning services and can help you determine the best process for your project. Our expert team will ensure that your parts are produced with the highest precision, whether you’re in automotive, machine building, or automation.

8. Advantages of Combining CNC Milling and CNC Turning

In some cases, a part may require both CNC milling and CNC turning to achieve the desired final shape. By combining these processes, manufacturers can create parts with more complex geometries while maintaining high levels of precision.

At CNCRUSH, we have the capability to combine both CNC milling and CNC turning in a single production cycle. This integrated approach offers several advantages:

- Reduced Production Time: Combining both processes in a single setup minimizes downtime and increases efficiency.

- Improved Precision: By using the same machine for both milling and turning, we can ensure that parts maintain tight tolerances across all dimensions.

- Cost Savings: Eliminating the need to transfer parts between different machines reduces handling costs and setup times.

9. How CNCRUSH Provides Expert CNC Machining Services

As a trusted provider of CNC machining services in China, CNCRUSH has over 12 years of experience delivering high-precision CNC Milled parts and CNC Turned parts to clients worldwide. Our advanced equipment, combined with our skilled team, allows us to meet the diverse needs of industries such as automotive, machine building, and automation.

- Custom CNC Solutions: We offer tailored solutions to meet your specific project requirements, whether you need CNC milling, CNC turning, or a combination of both.

- High-Quality Materials: We work with a wide range of materials, including aluminum, steel, brass, and plastics, ensuring that your parts are produced to the highest standards.

- Affordable CNC Machining: With our extensive experience and efficient processes, we provide cost-effective CNC machining services without compromising on quality.

10. FAQ: Frequently Asked Questions about CNC Milling and Turning

Q1: Can CNC milling and CNC turning be combined in a single operation?

A1: Yes, many modern CNC machines have both milling and turning capabilities, allowing for the creation of complex parts in a single operation.

Q2: What materials can be used in CNC milling and turning?

A2: Both processes can work with a variety of materials, including aluminum, steel, brass, and plastics.

Q3: What industries typically use CNC milling and CNC turning?

A3: Industries such as automotive, machine building, aerospace, and automation commonly use CNC milling and turning for producing high-precision parts.

In conclusion, both CNC milling and CNC turning offer unique advantages, depending on the type of part you need. By understanding the differences between these processes, you can make an informed decision and ensure that your parts meet the exact