CNC Machining transforms medical device production. Discover 12 game-changing strategies that boost quality and efficiency in CNC Milled parts, CNC Turned parts, and overall cnc machining service. CNC Machining is revolutionizing the production of medical device components by delivering unparalleled precision, consistency, and efficiency. In this comprehensive guide, we synthesize insights from top industry sources—including […]

Category Archives: CNCRUSH News

CNC Machining revolutionizes metalworking productivity. Discover 10 unstoppable strategies that boost efficiency, reduce downtime, and enhance CNC Milled parts and CNC Turned parts quality. CNC Machining is the driving force behind modern metalworking productivity, transforming the landscape of manufacturing by delivering unparalleled precision, speed, and quality. In this comprehensive guide, we draw upon insights from […]

CNC Machining is reshaping aerospace manufacturing with innovative techniques and precision. Discover 10 groundbreaking trends driving CNC Machining excellence in high-performance aerospace applications. CNC Machining is the driving force behind modern aerospace innovation, combining precision engineering with disruptive production techniques to meet the increasingly demanding requirements of the industry. This article synthesizes insights from multiple […]

CNC Machining revolutionizes high-volume production. Discover 7 powerful strategies that optimize cycle times, reduce setup times, and enhance CNC Milled parts and CNC Turned parts quality for automotive, machine building, and autumotion. CNC Machining stands as the backbone of modern manufacturing, driving unprecedented efficiency and precision in high-volume production environments. This comprehensive guide draws on […]

CNC Machined aluminum parts have revolutionized manufacturing. Discover 10 ultimate best practices for anodizing CNC machined aluminum parts with expert insights on CNC machining service, CNC Milled parts, and CNC Turned parts. CNC Machined aluminum parts have become the cornerstone of modern manufacturing, delivering unmatched precision and performance in industries such as automotive, machine building, […]

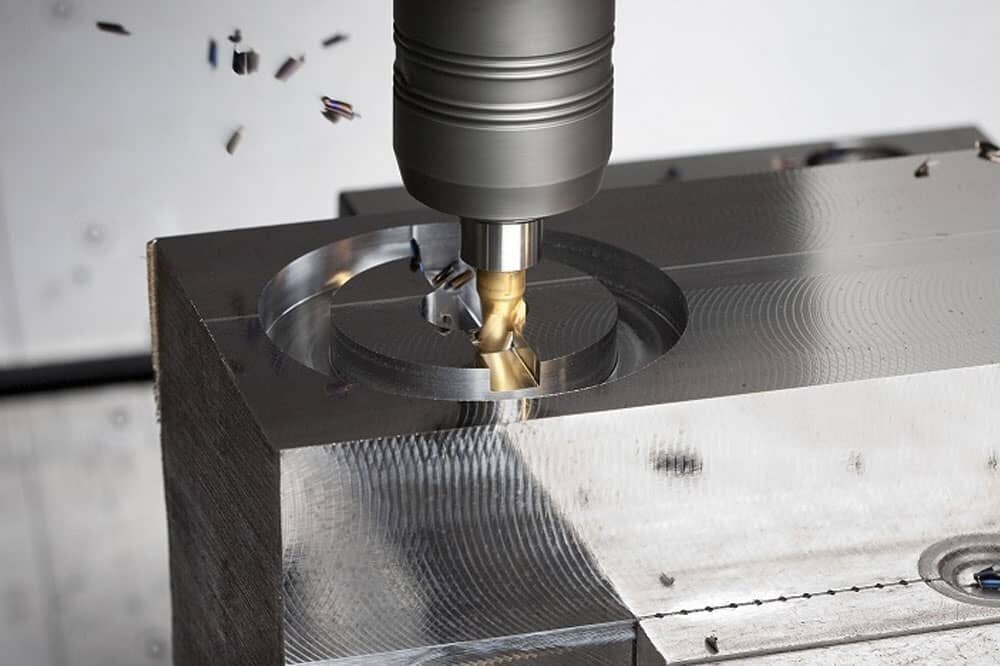

CNC Milling is a revolutionary process in precision metalworking that has fundamentally transformed modern manufacturing. Drawing insights from industry-leading sources on CNC milling, precision machining, and the latest technological advancements, this article provides an in-depth analysis of how CNC milling drives quality, efficiency, and innovation in metal fabrication. We will explore 10 critical topics—from an […]

CNC machining is pivotal for aerospace parts, requiring precision and reliability. Explore the best materials for aerospace CNC machining and how CNCRUSH’s CNC machining services deliver high-quality solutions. Introduction: A Comprehensive Look into CNC Machining for Aerospace Parts The aerospace industry is known for its high standards, especially when it comes to machining parts that […]

Discover how CNC machining services enhance quality in automotive manufacturing. Learn about CNC milled parts, CNC turned parts, and more. Trust CNCRUSH for precision. Introduction CNC machining has proven itself to be an indispensable asset in automotive manufacturing. From improving precision to ensuring the longevity and reliability of parts, this technology is at the core […]

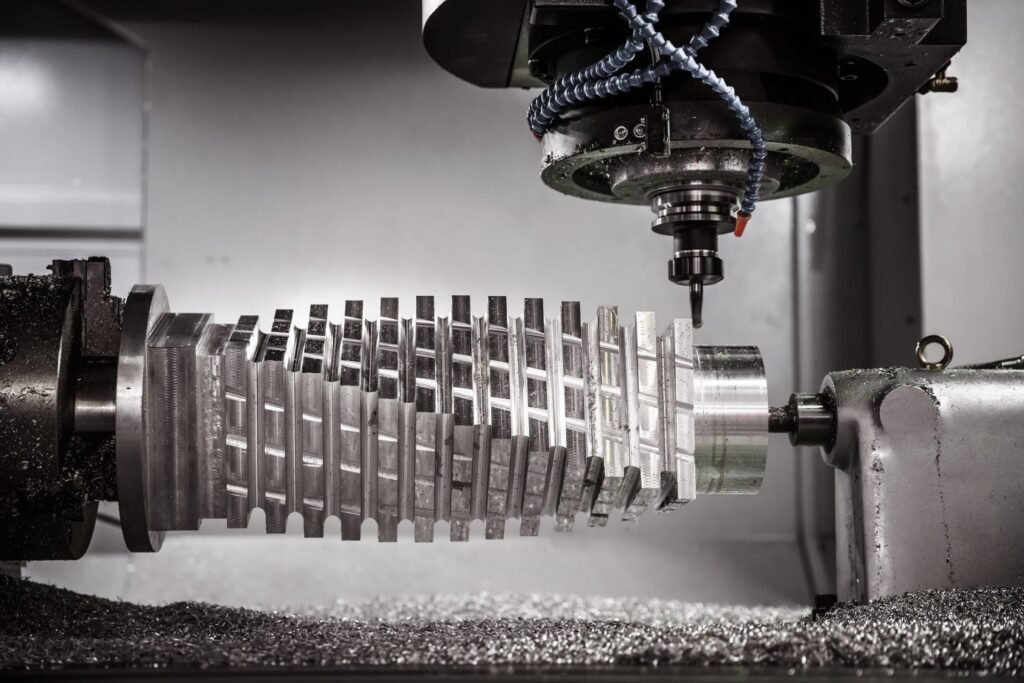

5-Axis CNC Machining is revolutionizing the manufacturing process for complex metal parts across industries. Whether you’re producing parts for automotive, aerospace, or machine building, this advanced technology is essential for creating high-precision, complex designs. At CNCRUSH, with over 12 years of experience in CNC machining services, we specialize in providing top-quality CNC milled parts and […]

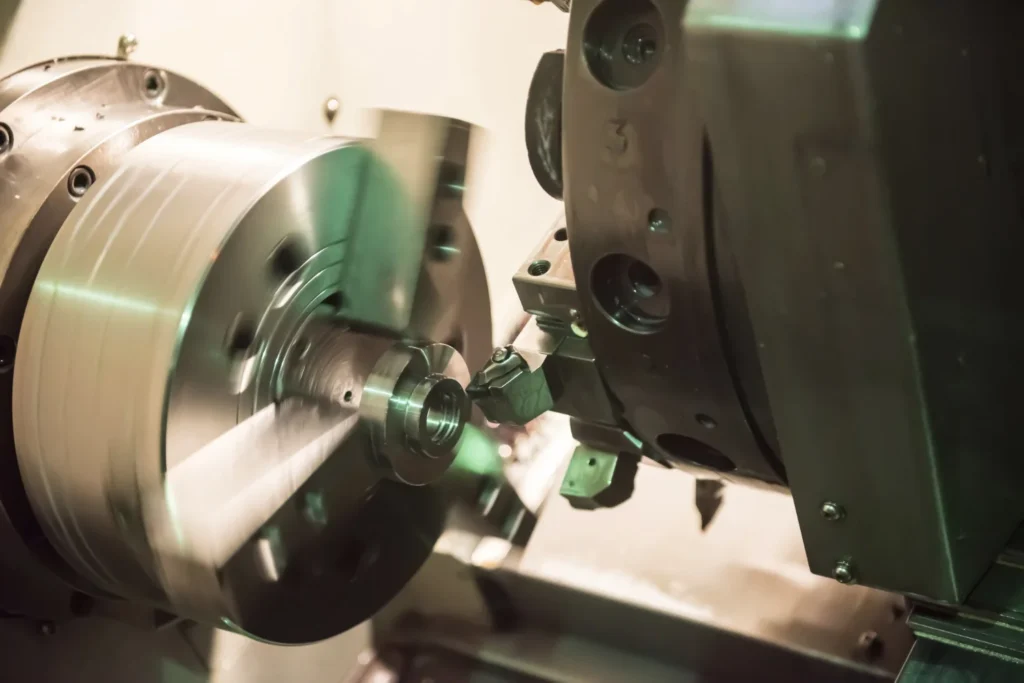

CNC machining is a crucial aspect of modern manufacturing, particularly in industries like automotive, machine building, and automation. One of the key factors that influence the efficiency and quality of CNC machining projects is cutting speed. By optimizing cutting speed, manufacturers can achieve faster production times while maintaining, or even improving, part quality. But how […]