CNC Milling is a revolutionary process in precision metalworking that has fundamentally transformed modern manufacturing. Drawing insights from industry-leading sources on CNC milling, precision machining, and the latest technological advancements, this article provides an in-depth analysis of how CNC milling drives quality, efficiency, and innovation in metal fabrication. We will explore 10 critical topics—from an overview of CNC milling to advanced 5-axis techniques and the impact of CNC Milled parts and CNC Turned parts on various industries. Read on to discover why CNC Milling is at the forefront of precision metalworking and how you can leverage our expertise for your next project.

CNC Milling: An Overview of its Role in Precision Metalworking

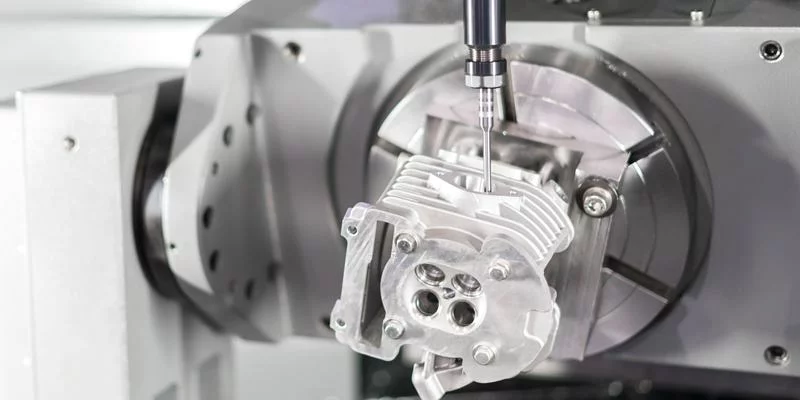

CNC Milling has emerged as a cornerstone of modern manufacturing by enabling highly precise and repeatable production of complex metal parts. This process utilizes computer numerical control (CNC) machines to remove material from a workpiece, shaping it into the desired form with exceptional accuracy. The transformation from manual machining to CNC Milling has been nothing short of revolutionary, providing not only consistency but also flexibility in production.

In today’s competitive manufacturing landscape, precision is paramount. CNC Milling meets these demands by ensuring tight tolerances and superior surface finishes. The integration of advanced software with robust hardware systems means that even the most intricate parts can be manufactured with minimal error. With these benefits, CNC Milling has become indispensable for industries such as automotive, aerospace, machine building, and automotion.

The power of CNC Milling lies in its ability to deliver repeatable quality, reduce labor costs, and enhance productivity. Its evolution over the past decades has paralleled the rapid advancements in digital technology, making it a highly adaptive and efficient manufacturing process.

CNC Machining Service: Revolutionizing Metal Fabrication

The rise of cnc machining service providers has been instrumental in revolutionizing metal fabrication. By leveraging state-of-the-art machinery and automation, manufacturers can produce high-quality parts at a fraction of the time required by traditional methods. This revolution is especially evident in the realm of CNC Milling, where precision and efficiency go hand in hand.

Our advanced cnc machining service incorporates cutting-edge technology, allowing us to handle complex projects with ease. We offer tailored solutions that range from one-off prototypes to large-scale production runs. Clients benefit from our comprehensive services, which include not only machining but also finishing processes like anodizing and plating.

Embracing a modern cnc machining service means embracing innovation. For instance, the integration of real-time process monitoring and automated quality control systems minimizes human error and ensures consistent production quality. This shift towards automated, digitally controlled manufacturing has made CNC Milling an industry standard, especially in sectors where precision is non-negotiable.

The Evolution of CNC Milled Parts in Modern Manufacturing

The journey of CNC Milled parts from rudimentary components to highly complex assemblies mirrors the evolution of manufacturing itself. Initially, CNC machines were limited by the technology of their era; however, as both hardware and software have advanced, so too has the capability of CNC Milling.

Today, CNC Milled parts are synonymous with high precision and repeatability. These parts are manufactured using sophisticated multi-axis machines that can tackle intricate geometries and challenging materials. The evolution of these parts has opened up new possibilities for design and innovation in industries ranging from medical devices to automotive components.

Our commitment to delivering superior CNC Milled parts is backed by 12 years of industry expertise. At CNCRUSH, we harness the latest in CNC technology to produce parts that meet even the most stringent quality standards. Our focus on precision, coupled with our advanced machinery, ensures that every component we produce is a testament to modern engineering excellence.

CNC Turned Parts: Enhancing Component Quality and Consistency

Just as CNC Milling plays a critical role in metal fabrication, CNC Turned parts have become vital for achieving excellent surface finishes and dimensional accuracy in rotational components. CNC turning, which involves the use of lathes to shape parts, complements CNC Milling by producing components with circular symmetry.

The process of CNC turning allows for the high-speed production of parts with complex contours and fine tolerances. These CNC Turned parts are widely used in industries where performance and precision are critical, such as in engine components, medical devices, and high-precision instruments.

At CNCRUSH, our expertise in CNC turning is a key component of our comprehensive cnc machining service. We ensure that every CNC Turned part we produce is manufactured to exacting standards, guaranteeing consistency and reliability in every batch. This dedication to quality underscores our commitment to excellence and our passion for innovative metalworking solutions.

CNC Machining Service for Automotive, Machine Building, and Automotion Industries

The demand for advanced cnc machining service has grown exponentially in industries like automotive, machine building, and automotion. These sectors require parts that are not only precise but also durable enough to withstand extreme conditions. CNC Milling is particularly well-suited for these applications, offering unparalleled precision and material versatility.

In the automotive industry, CNC Milling is used to create components that contribute to both the performance and safety of vehicles. From engine blocks to transmission parts, the process ensures that each component meets rigorous quality standards. Similarly, in machine building and automotion, CNC Machining Services streamline production processes, reduce waste, and ensure that every part fits perfectly within the larger assembly.

By choosing our cnc machining service, clients gain access to cutting-edge technology and a team dedicated to continuous improvement. Our proven track record over 12 years means that we understand the unique challenges of these industries and are well-equipped to provide solutions that drive success.

Advanced CNC Milling Techniques: 5-Axis Machining and Beyond

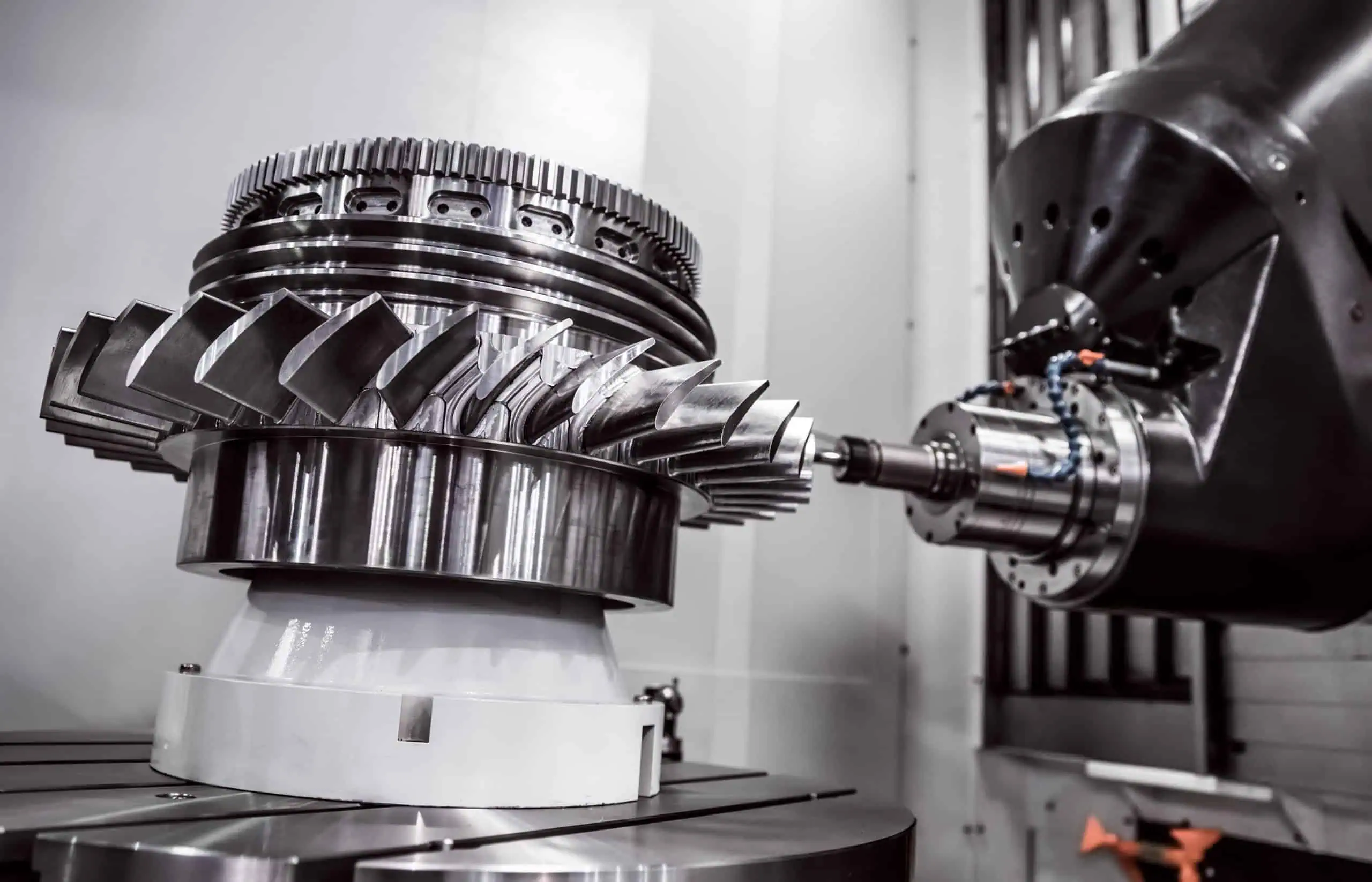

The advancements in CNC Milling technology have led to the development of sophisticated techniques such as 5-axis machining. This innovation allows for simultaneous multi-dimensional cutting, enabling the production of parts with complex geometries that were previously unachievable.

5-axis machining enhances the capabilities of CNC Milling by allowing for more precise tool positioning and faster production times. This method not only improves accuracy but also minimizes the need for multiple setups, which reduces production time and costs. The result is a highly efficient process that produces intricate parts with excellent surface quality.

Our investment in advanced CNC Milling technology, including 5-axis machining, reflects our commitment to delivering innovative solutions. At CNCRUSH, we continuously upgrade our equipment to stay at the forefront of the industry, ensuring that our cnc machining service meets the evolving needs of our clients. This progressive approach has garnered a reputation for excellence and reliability in precision metalworking.

Quality Assurance in CNC Milled Parts: Ensuring Precision and Durability

Quality assurance is a critical aspect of producing top-tier CNC Milled parts. From the initial design to the final inspection, every step in the CNC Milling process is monitored to ensure that the end product meets stringent quality standards. The integration of advanced inspection tools and automated control systems has significantly improved the consistency and accuracy of CNC Milling operations.

Positive sentiment surrounds the progress in quality assurance practices within the CNC Milling industry. Manufacturers are now able to detect and correct issues in real time, thereby reducing scrap rates and ensuring customer satisfaction. This level of precision is crucial in industries where even the slightest deviation can lead to significant problems.

At CNCRUSH, quality is at the heart of our cnc machining service. Our comprehensive quality control processes include rigorous testing and inspection at every stage of production. This ensures that every CNC Milled part not only meets but exceeds industry standards, providing our clients with reliable, high-performance components.

The Impact of CNC Turned Parts on Efficiency and Production

The efficiency gains from incorporating CNC Turned parts into production lines are substantial. CNC turning, with its ability to produce parts quickly and with high precision, directly impacts overall production efficiency. This process reduces lead times and allows for rapid prototyping and mass production without sacrificing quality.

One of the most compelling benefits of CNC Turned parts is their ability to enhance consistency across large production runs. The automation inherent in CNC turning minimizes human error and ensures that each part is identical to the last. This reliability is particularly important in high-stakes industries where product failure can have severe consequences.

Our dedication to producing high-quality CNC Turned parts is reflected in our state-of-the-art facilities and the expertise of our team. At CNCRUSH, we pride ourselves on delivering cnc machining service solutions that boost production efficiency and drive operational success. Our focus on continuous improvement means that we are always looking for ways to optimize our processes and deliver even greater value to our customers.

Comparative Analysis: CNC Milling vs. Other Machining Processes

Understanding the distinct advantages of CNC Milling requires a comparative look at traditional machining processes. Below is a table that outlines the key differences between CNC Milling, CNC Turning, and Conventional Machining:

| Feature | CNC Milling | CNC Turning | Conventional Machining |

|---|---|---|---|

| Precision | Extremely high, suitable for intricate designs | High precision for rotational parts | Variable, depends on manual operation |

| Complexity Handling | Capable of 3D and multi-axis machining | Best for cylindrical and conical parts | Limited to simple geometries |

| Production Efficiency | High efficiency with automated setups | Fast for repetitive, rotational tasks | Lower due to manual intervention |

| Surface Finish | Superior, with advanced finishing options | Excellent for rotational symmetry | Inconsistent surface quality |

| Material Versatility | Works with a wide range of materials | Ideal for metals and alloys | Often limited by tooling and operator skill |

Table 1: Comparative Analysis of Machining Processes

In addition to the technical advantages outlined above, CNC Milling also offers significant improvements in cost efficiency and production time. Its ability to perform multi-axis operations in a single setup minimizes downtime and reduces the risk of errors, ultimately delivering a more streamlined manufacturing process.

A second table highlights the various industries that benefit from CNC Milling and their typical applications:

| Industry | Application | Key Benefit |

|---|---|---|

| Automotive | Engine components, transmission parts | High precision and durability |

| Aerospace | Structural components, turbine parts | Lightweight and robust design |

| Medical | Surgical instruments, implantable devices | Sterile, precise, and consistent |

| Machine Building | Gears, housings, and structural frames | Customization and reliability |

| Automotion | Robotic components, automated machinery parts | Efficiency and high repeatability |

Table 2: Industries and Applications for CNC Milling

This comparative analysis underscores why CNC Milling is increasingly preferred over other machining methods. Its adaptability, precision, and efficiency make it an ideal choice for modern manufacturing challenges.

CNCRUSH: Your Trusted CNC Machining Service Partner in China

For over 12 years, CNCRUSH has been at the forefront of delivering high-quality cnc machining service to clients worldwide. As a professional China-based factory, we specialize in both CNC Milled parts and CNC Turned parts, catering to industries such as automotive, machine building, and automotion. Our state-of-the-art facility and experienced team enable us to tackle complex projects with confidence and precision.

At CNCRUSH, we understand that every project is unique. Our comprehensive range of services—from CNC Milling and turning to advanced surface treatments like anodizing and plating—ensures that we can meet your specific manufacturing requirements. We take pride in our commitment to quality, efficiency, and customer satisfaction, which has earned us the trust of global clients over the years.

Our website, CNCRUSH, is your gateway to exploring our full range of capabilities and learning more about our cnc machining service offerings. Whether you need a one-off prototype or a large-scale production run, we are ready to partner with you and help bring your vision to life. With a focus on innovation and continuous improvement, CNCRUSH remains dedicated to pushing the boundaries of precision metalworking.

FAQ

Q1: What is CNC Milling?

A1: CNC Milling is a computer-controlled process used to remove material from a workpiece to create precise, complex shapes. It is widely used in precision metalworking for its ability to produce high-quality parts with tight tolerances.

Q2: How does CNC Milling differ from CNC Turning?

A2: CNC Milling removes material using rotary cutters and multi-axis movements, making it ideal for complex shapes and surfaces, whereas CNC Turning involves rotating the workpiece against a stationary cutting tool, best suited for cylindrical parts.

Q3: What industries benefit most from CNC Milling?

A3: Industries such as automotive, aerospace, medical, machine building, and automotion greatly benefit from CNC Milling due to its precision, efficiency, and versatility in handling various materials.

Q4: Why should I choose CNCRUSH for my machining needs?

A4: CNCRUSH has over 12 years of experience in providing high-quality cnc machining service, specializing in CNC Milled parts and CNC Turned parts. We offer advanced manufacturing solutions, including 5-axis CNC Milling and comprehensive surface treatments, ensuring exceptional quality and reliability.

Q5: What are the key advantages of 5-axis CNC Milling?

A5: 5-axis CNC Milling allows for simultaneous multi-dimensional cutting, reducing the need for multiple setups, increasing accuracy, and enabling the production of intricate parts with complex geometries.

Conclusion: The Future is Bright for CNC Milling in Precision Metalworking

The evolution of CNC Milling is a testament to the relentless drive for innovation in precision metalworking. From its humble beginnings to its current role as a transformative force in manufacturing, CNC Milling has consistently delivered improved accuracy, efficiency, and cost-effectiveness. The integration of advanced techniques such as 5-axis machining and the continual refinement of CNC Milled parts and CNC Turned parts production are clear indicators of the bright future ahead.

In today’s competitive landscape, manufacturers need reliable, cutting-edge technology to maintain their edge. Our in-depth exploration has shown that the benefits of CNC Milling extend beyond mere production efficiency—they enable the creation of complex, high-quality components that push the boundaries of what is possible. This technology is particularly impactful in high-stakes industries like automotive, machine building, and automotion, where precision and durability are paramount.

At CNCRUSH, our passion for excellence drives us to continually innovate and refine our processes. We are proud to offer comprehensive cnc machining service solutions that include advanced CNC Milling, turning, and surface treatment processes. As you explore new projects and expand your production capabilities, we invite you to experience the CNCRUSH difference.

By choosing our services, you join a community of forward-thinking manufacturers who recognize the value of precision, efficiency, and innovation. Visit our website at CNCRUSH to learn more about our offerings and see firsthand how our expertise in CNC Milling can transform your production processes.

The journey of CNC Milling is not just about technology—it’s about building a future where quality and precision drive progress. With a proven track record, an unwavering commitment to excellence, and a suite of advanced manufacturing solutions, CNCRUSH is here to empower your business every step of the way.