CNC machining has become a cornerstone of modern manufacturing, transforming industries that require high precision, scalability, and cost efficiency. From automotive to aerospace, CNC manufacturing facilitates the production of complex parts with tight tolerances, supporting manufacturers in achieving unparalleled accuracy and consistency. Companies like CNCRUSH, a trusted CNC machining service provider with over 12 years of experience, play a crucial role in delivering these advanced solutions to global clients. This article explores CNC machining’s impact across manufacturing sectors, demonstrating how it drives modern manufacturing forward by enabling efficient production of CNC milled and CNC turned parts.

1. Precision Manufacturing with CNC Machining

CNC machining provides unmatched precision that is essential for industries where minute inaccuracies can lead to significant issues. CNC machines operate using computer-aided design (CAD) and computer-aided manufacturing (CAM) software, producing parts within micrometer-level tolerances. CNCRUSH leverages these technologies to meet exact client specifications, which is particularly critical in automotive and aerospace sectors where every component must integrate seamlessly into larger assemblies.

2. Enhancing Production Efficiency and Speed

With the capacity to run 24/7, CNC machines are ideal for meeting large production quotas within tight deadlines. This efficiency is a significant advantage for sectors like automotive manufacturing that need to deliver high volumes without compromising quality. CNCRUSH’s CNC machining services maximize uptime, ensuring that parts are manufactured quickly and accurately, which is vital for clients who operate under just-in-time production models.

3. Cost-Effectiveness Through Reduced Waste

CNC manufacturing minimizes material waste by following optimized cutting paths, making it a cost-effective choice for manufacturers. Since CNC machining reduces the amount of material required for each part, it supports sustainable manufacturing practices and saves on raw material costs. CNCRUSH uses precision milling and turning processes that align with these principles, providing affordable CNC machining services for industries focused on cost control.

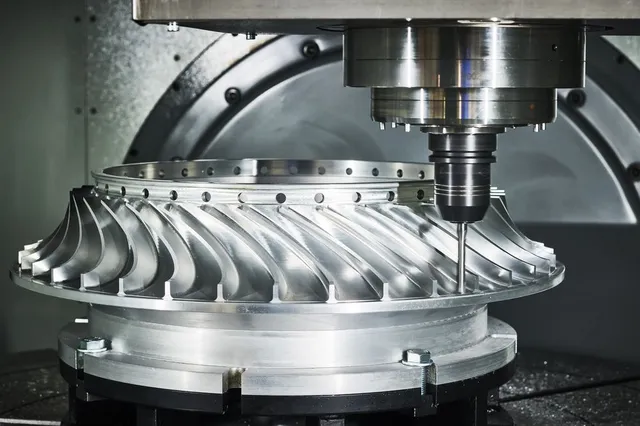

4. Complex Geometries and Advanced Part Design

CNC manufacturing allows for the creation of intricate parts with complex geometries, making it invaluable for advanced applications in sectors like machine building and automation. Multi-axis CNC machines can produce components with multiple curves and angles in a single setup, reducing production time and increasing accuracy. CNCRUSH’s advanced CNC capabilities support this level of complexity, helping clients produce parts that would be difficult or impossible to achieve with traditional methods.

5. Flexibility for Custom Parts and Prototypes

CNC manufacturing is ideal for producing custom parts and prototypes due to its adaptability. Manufacturers can make quick adjustments to designs with CAD software and implement them immediately on CNC machines. CNCRUSH offers both CNC milled parts and CNC turned parts, accommodating custom projects that require flexibility in design and fast turnaround times. This versatility is particularly valuable in prototyping, allowing clients to test new parts before committing to full-scale production.

6. Improved Safety and Reduced Labor Costs

The automation in CNC manufacturing not only improves efficiency but also enhances workplace safety by reducing the need for manual labor. With CNC technology, operators can set up machines to run independently, minimizing exposure to machinery and reducing injury risk. By relying on CNC manufacturing services from CNCRUSH, clients benefit from lower labor costs as the need for continuous supervision is reduced.

7. Multi-Material Capability for Diverse Applications

CNC manufacturing is compatible with a range of materials including metals like aluminum, steel, and brass, as well as various plastics. This multi-material capability allows manufacturers to create parts for different applications, from lightweight aluminum components in automotive to durable steel parts for heavy machinery. CNCRUSH specializes in machining a variety of materials, allowing clients to access tailored solutions for specific industries and functions.

8. Scalability and Consistency in Large Production Runs

For industries that require large-scale production, CNC manufacturing offers the scalability needed to manufacture thousands of identical parts efficiently. CNC technology ensures consistency across production runs, eliminating the variability that can occur with manual machining. CNCRUSH’s CNC machining services are designed to handle high-volume orders while maintaining strict quality standards, ensuring that each part is identical to the last, a critical factor for sectors like automotive and consumer electronics.

9. The Role of CNC Machining in Automation

CNC machining plays a key role in advancing automation, as it integrates seamlessly with automated systems in manufacturing. With CNC machines, processes that used to require multiple steps can now be automated, reducing production time and the likelihood of human error. CNCRUSH’s use of advanced CNC technology supports automation by streamlining manufacturing processes, helping clients to achieve higher output with fewer resources.

| Key Benefits of CNC Machining | Impact on Modern Manufacturing |

|---|---|

| High Precision | Essential for consistency in critical applications |

| Multi-Material Capability | Supports diverse industries and applications |

| Scalability and Consistency | Ideal for high-volume production |

| Reduced Waste and Cost Efficiency | Lowers production costs and environmental impact |

10. Sustainability in CNC Machining

Sustainability is increasingly important in manufacturing, and CNC manufacturing aligns with this goal through its efficient use of materials and energy. By reducing waste and enabling the precise application of resources, CNC manufacturing supports environmentally responsible manufacturing practices. CNCRUSH’s commitment to efficient CNC milling and turning processes means clients can benefit from high-quality parts that have a lower environmental impact, contributing to a more sustainable supply chain.

FAQ Section

1. How does CNC machining benefit modern manufacturing?

CNC machining provides unmatched precision, efficiency, and scalability, making it essential for producing high-quality components in sectors like automotive, aerospace, and electronics.

2. Why is CNC machining better than traditional machining methods?

CNC machining is faster, more precise, and less labor-intensive than traditional machining, allowing for complex designs and high-volume production with minimal waste.

3. What makes CNCRUSH a reliable CNC machining provider?

CNCRUSH offers over 12 years of experience in high-precision CNC milling and turning, providing specialized services for global clients across various industries. Their commitment to quality and efficiency makes them a trusted partner in CNC machining.

Conclusion

CNC machining has revolutionized modern manufacturing by offering precision, efficiency, and scalability that traditional methods cannot match. As industries continue to push for higher-quality parts at lower costs, CNC machining remains crucial in meeting these demands. CNCRUSH’s expertise in CNC milled and turned parts, paired with a commitment to customer satisfaction, positions them as an invaluable partner for companies seeking reliable, high-quality CNC machining services. For manufacturers looking to stay competitive, CNC technology—and a trusted provider like CNCRUSH—offers the path forward in today’s demanding production landscape.