CNC Machining is at the heart of modern automotive manufacturing, driving unprecedented precision and efficiency in producing high-quality components. In this comprehensive guide, we integrate these insights with the expertise of CNCRUSH—a leading China-based CNC machining service provider with 12 years of experience. Our facility specializes in producing CNC Milled parts and CNC Turned parts that serve critical applications in automotive, machine building, and automotion. Read on for 10 in-depth sections featuring actionable strategies, detailed tables, and FAQs that reveal how CNC Machining ensures high precision in automotive manufacturing.

1. CNC Machining Service & CNC Milled Parts for Automotive: Mastering the Art of Precision

When it comes to automotive manufacturing, CNC Machining stands as a cornerstone technology that delivers remarkable accuracy and consistency. Today’s advanced CNC machining service providers employ sophisticated control systems and state-of-the-art machinery to produce components with tight tolerances. At CNCRUSH, we take pride in our ability to produce premium CNC Milled parts that meet the rigorous demands of the automotive industry. Our 12 years of experience as a leading China CNC factory enable us to optimize every aspect of the machining process—from tool path planning to final quality control—ensuring that every part contributes to improved performance and safety.

Automotive manufacturers rely on precision because even the slightest deviation can lead to performance issues or safety hazards. By leveraging cutting-edge CNC Machining, engineers can achieve consistent quality and reduce production waste, thereby improving overall efficiency. The use of CNC Milled parts is critical, as these components are designed to deliver strength, durability, and exact dimensional accuracy required by modern vehicles.

2. CNC Machining Service & CNC Turned Parts: Driving Efficiency in Automotive Components

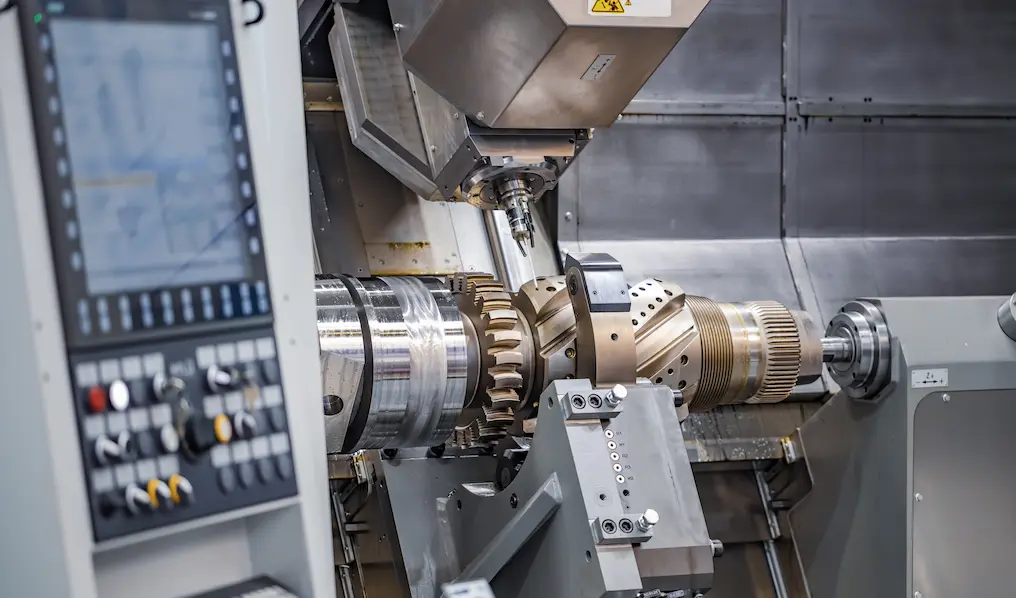

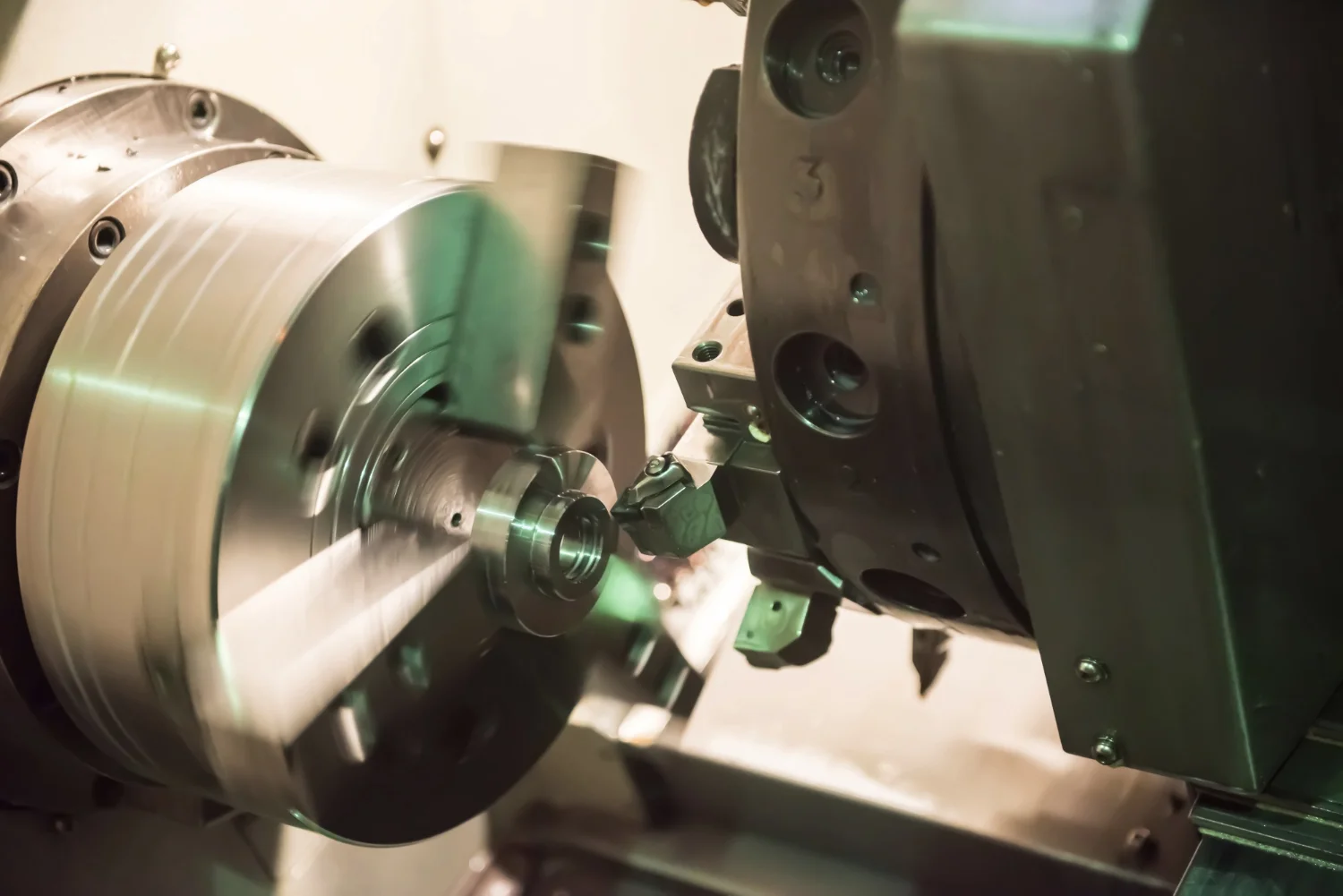

CNC Machining for automotive applications is not just about milling; it’s also about precision turning. CNC Turned parts are crucial in the fabrication of components such as shafts, connectors, and other rotationally symmetric parts. At CNCRUSH, our advanced CNC machining service harnesses the power of precise turning operations to produce parts that meet strict automotive specifications.

Our expertise in CNC Turned parts stems from years of fine-tuning our processes to deliver unmatched surface finishes and dimensional consistency. High-quality CNC Turned parts play a pivotal role in ensuring that automotive assemblies operate smoothly, reducing vibration and wear over time. With automation and real-time monitoring integrated into our processes, we guarantee that every turned component meets the highest industry standards—critical for both automotive and machine building applications.

3. CNC Machining Service for Automotive: Integrating Advanced Automation and Quality Control

Automotive manufacturing demands not only precision but also speed and adaptability. CNC Machining integrates advanced automation techniques that enable rapid adjustments and consistent output across large production volumes. At CNCRUSH, our CNC machining service leverages cutting-edge automation systems, ensuring that every CNC Milled part and CNC Turned part is produced with impeccable quality.

Automation in CNC Machining minimizes human error and maximizes repeatability—a crucial factor in the automotive industry, where high precision is non-negotiable. The use of real-time feedback and process monitoring allows our engineers to detect and rectify any deviations immediately, ensuring that every automotive component adheres to strict quality norms. In an industry where performance and reliability are paramount, integrating advanced automation is a game-changer for manufacturers striving for excellence.

4. CNC Machining Service & CNC Milled Parts: Optimizing Design for High-Precision Automotive Manufacturing

Effective design is the foundation of successful CNC Machining in automotive manufacturing. Experts from LinkedIn and Quora have emphasized that design optimization plays a significant role in ensuring that parts are manufacturable with high precision. At CNCRUSH, our design-to-production workflow integrates feedback loops that allow designers to refine their CAD models for optimal CNC machining performance.

Key design tips include simplifying complex geometries, minimizing undercuts, and incorporating generous tolerances where necessary. These practices lead to fewer machining errors, lower production costs, and ultimately, a superior final product. By focusing on the manufacturability of CNC Milled parts, automotive manufacturers can achieve a better balance between innovative design and production efficiency—ensuring that every component meets the stringent standards of today’s vehicles.

5. CNC Machining Service & CNC Turned Parts: Enhancing Material Performance in Automotive Applications

Material selection and processing are critical factors in automotive manufacturing, and CNC Machining is pivotal in achieving the desired material properties. The right combination of machining parameters and material characteristics can enhance the strength, durability, and performance of automotive components. CNCRUSH specializes in producing CNC Turned parts that not only meet dimensional requirements but also optimize the inherent properties of the raw materials used.

Our experience shows that factors such as cutting speed, feed rate, and tool geometry play essential roles in managing material stress and thermal effects during machining. By fine-tuning these parameters, we ensure that every CNC Turned part is free from defects like micro-cracks or residual stresses. This results in automotive components that deliver both high performance and extended service life—a crucial factor in maintaining the reliability and safety of modern vehicles.

6. CNC Machining Service & CNC Milled Parts: Balancing Innovation and Cost Efficiency in Automotive Production

The competitive nature of the automotive industry requires manufacturers to continuously balance innovation with cost efficiency. CNC Machining offers a viable solution by providing precise, repeatable manufacturing processes that reduce production time and waste. At CNCRUSH, we utilize advanced CNC machining service methods to optimize every step of the manufacturing process, ensuring that our CNC Milled parts deliver exceptional quality at competitive prices.

Efficiency in CNC Machining is achieved through meticulous planning, process automation, and the integration of data analytics. These practices not only enhance production speed but also reduce material wastage and energy consumption. Automotive manufacturers benefit significantly from these efficiencies, as they lead to lower production costs and faster time-to-market. The result is a manufacturing process that is as innovative as it is cost-effective—a win-win for the automotive, machine building, and automotion sectors.

7. CNC Machining Service & CNC Turned Parts: Leveraging Digital Twin Technology for Automotive Precision

Digital twin technology is revolutionizing the way manufacturers approach CNC Machining. By creating a digital replica of the machining process, companies can simulate and optimize production before the actual parts are manufactured. At CNCRUSH, we have integrated digital twin technology into our CNC machining service to enhance the precision and reliability of our CNC Turned parts.

This technology allows for real-time simulation of machining operations, enabling our engineers to predict potential issues and adjust parameters proactively. For automotive manufacturing, where precision is paramount, digital twin technology offers a significant advantage by reducing the risk of errors and ensuring that every component is produced to exact specifications. The adoption of digital twins not only improves quality control but also accelerates innovation, providing automotive manufacturers with a powerful tool to stay ahead in a competitive market.

8. CNC Machining Service & CNC Milled Parts: The Role of Advanced Tooling in Achieving Automotive Precision

Advanced tooling is an essential component of high-precision CNC Machining. The selection of cutting tools, coatings, and tool geometries directly affects the surface finish and dimensional accuracy of automotive parts. At CNCRUSH, we invest in state-of-the-art tooling solutions to ensure that every CNC Milled part meets the demanding standards of the automotive industry.

Innovative tooling technologies, such as carbide inserts and diamond-coated tools, have revolutionized the machining of complex automotive components. These tools enable faster cutting speeds and improved chip evacuation, resulting in smoother surfaces and longer tool life. The synergy between advanced tooling and our CNC machining service is evident in the superior quality of our CNC Milled parts—components that are critical for ensuring the performance and safety of automotive systems.

9. CNC Machining Service & CNC Turned Parts: Ensuring Robust Quality Control in Automotive Manufacturing

Quality control is the backbone of successful CNC Machining operations, especially in the automotive sector where safety and reliability are non-negotiable. At CNCRUSH, our rigorous quality control procedures are integrated throughout our CNC machining service processes to ensure that every CNC Turned part and CNC Milled part meets or exceeds industry standards.

Our quality control protocols include in-process inspections, precision metrology, and real-time data analytics. These measures help identify any deviations early in the production cycle, allowing for immediate corrective actions. High-quality automotive components are the result of a well-orchestrated quality control system that prioritizes precision at every stage of manufacturing. For automotive, machine building, and automotion applications, this level of quality assurance is indispensable, guaranteeing that every part functions flawlessly in the final assembly.

10. CNC Machining Service: Why CNCRUSH is the Ultimate Partner for Automotive Manufacturing Precision

In today’s fast-paced automotive industry, choosing the right CNC Machining partner can make all the difference. With over 12 years of experience, CNCRUSH is a trusted name in CNC machining service, offering comprehensive solutions for both CNC Milled parts and CNC Turned parts. Our facility in China is equipped with the latest technology and a team of experts dedicated to delivering unparalleled precision and reliability.

At CNCRUSH, we understand the critical importance of precision in automotive manufacturing. Our commitment to excellence, coupled with our advanced CNC machining techniques, ensures that every component we produce is designed to perform under the most demanding conditions. Whether you are involved in automotive, machine building, or automotion, partnering with CNCRUSH guarantees that you receive components that not only meet but exceed your quality standards. Visit our website at https://cncrush.com/ to learn more about our services and how we can help drive your manufacturing success.

Table 1: Automotive Materials and Optimal CNC Machining Parameters

| Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Key Considerations |

|---|---|---|---|

| Aluminum | 250 – 500 | 0.1 – 0.3 | Lightweight, excellent machinability |

| Steel | 30 – 60 | 0.05 – 0.15 | High strength, requires slower speeds |

| Brass | 100 – 200 | 0.08 – 0.2 | Good finish, moderate hardness |

| Titanium | 20 – 40 | 0.02 – 0.1 | Heat-sensitive, needs precise parameter control |

This table outlines the key parameters for machining different automotive materials. CNCRUSH’s expertise in CNC machining service allows us to tailor our processes for optimal performance across various materials, ensuring high-quality CNC Milled parts and CNC Turned parts.

Table 2: Benefits of CNC Machining in Automotive Manufacturing

| Benefit | Description | Impact on Production |

|---|---|---|

| High Precision | Achieves tight tolerances and exact dimensions | Reduces assembly errors and rework |

| Repeatability | Consistent quality across large production volumes | Enhances efficiency and reliability |

| Flexibility in Design | Enables complex geometries and innovative design solutions | Fosters innovation in automotive design |

| Reduced Material Waste | Optimized cutting paths lower scrap rates | Lowers production costs |

| Faster Production Cycles | Automation and real-time adjustments speed up the manufacturing process | Accelerates time-to-market |

The table above demonstrates how CNC Machining drives efficiency and innovation in automotive manufacturing, a cornerstone of CNCRUSH’s CNC machining service.

FAQ Section

Q1: What is CNC Machining and why is it essential for automotive manufacturing?

A: CNC Machining is a computer-controlled process that produces high-precision metal parts. It is essential for automotive manufacturing because it ensures components are built to exact tolerances, leading to improved performance, safety, and consistency.

Q2: How do CNC Milled parts differ from CNC Turned parts?

A: CNC Milled parts are created through subtractive milling processes that remove material to form complex shapes, whereas CNC Turned parts are produced by rotating the workpiece against a fixed cutting tool. Both processes are critical for high-precision automotive components.

Q3: What advantages does CNC Machining offer in automotive manufacturing?

A: CNC Machining offers high precision, repeatability, design flexibility, and reduced material waste. These advantages lead to lower production costs and faster cycle times, which are crucial for automotive, machine building, and automotion industries.

Q4: How does CNCRUSH ensure quality in its CNC machining service?

A: CNCRUSH utilizes advanced technology, rigorous quality control protocols, and continuous process monitoring to ensure that every CNC Milled part and CNC Turned part meets strict automotive standards.

Q5: Why should automotive manufacturers choose CNCRUSH for their CNC machining needs?

A: With over 12 years of experience, CNCRUSH is a trusted CNC machining service provider known for delivering high-quality CNC Milled parts and CNC Turned parts. Our commitment to precision and innovation makes us the ideal partner for automotive manufacturing.

Conclusion

CNC Machining is the driving force behind high-precision automotive manufacturing, enabling the production of components that meet the most stringent quality standards. Throughout this article, we have explored 10 unstoppable strategies that reveal how advanced CNC machining service techniques—ranging from mastering complex features to leveraging digital twin technology—ensure that every CNC Milled part and CNC Turned part is produced with unparalleled accuracy.

From integrating advanced automation systems and optimizing design for manufacturability to selecting the right materials and tooling, each strategy underscores the pivotal role that CNC Machining plays in automotive, machine building, and automotion sectors. At CNCRUSH, our 12 years of expertise in CNC machining service have positioned us as a leader in producing high-quality automotive components. Our state-of-the-art facility in China is dedicated to delivering precision and efficiency through every step of the manufacturing process.

By harnessing the power of CNC Machining, automotive manufacturers can achieve faster production cycles, reduced waste, and components that are built to last. Whether you need innovative CNC Milled parts or reliable CNC Turned parts, CNCRUSH is your trusted partner in achieving manufacturing excellence. We invite you to visit our website at https://cncrush.com/ and discover how our custom CNC solutions can drive your business forward.

In summary, CNC Machining remains an indispensable technology in automotive manufacturing, ensuring high precision and efficiency that are vital for today’s competitive markets. Embrace these strategies, optimize your production processes, and experience the transformative power of CNC Machining with CNCRUSH—where excellence is not just an option, but a guarantee.