CNC Machining is revolutionizing the aerospace industry by driving unprecedented precision, efficiency, and innovation. Drawing insights from top-tier sources such as Fictiv, Aerospace & Defense Review, Methods Machine, LMW CNC, 3DS, LinkedIn industry experts, and Manufacturing Tomorrow, this article provides an in-depth analysis of how advanced machining technologies are transforming aerospace manufacturing. The original materials highlight the benefits of integrating high-speed, precision machining with advanced materials and digital innovations. They explore how cutting-edge CNC machining techniques improve component integrity, reduce production costs, and pave the way for smarter, more sustainable aerospace production.

1. CNC Machining Service: Transforming Aerospace Manufacturing

CNC Machining is at the forefront of aerospace manufacturing, offering the ability to create complex, high-precision components that meet rigorous industry standards. In aerospace, every part—from engine components to structural supports—must withstand extreme conditions while maintaining lightweight properties. CNC machining provides the versatility and accuracy needed for such applications.

Modern aerospace manufacturers increasingly rely on advanced CNC machining service providers to ensure that components are produced with impeccable precision. With automated controls and real-time feedback systems, CNC machining minimizes human error and enhances repeatability—a necessity in a field where even minor deviations can lead to catastrophic failures. At CNCRUSH, our commitment to precision CNC machining services has positioned us as leaders in producing both CNC Milled parts and CNC Turned parts. Our 12-year track record underscores our ability to deliver aerospace components that exceed expectations in performance and durability.

2. CNC Machining Service: The Critical Role of CNC Milled Parts in Aerospace Innovation

CNC Machining plays a pivotal role in fabricating the intricate geometries required for modern aerospace designs. CNC Milled parts are essential in creating components with tight tolerances and complex contours, which are common in aerospace applications. These parts are not only designed for strength and reliability but also for weight reduction—a critical factor in aerospace efficiency.

Advances in CNC machining have enabled manufacturers to experiment with new materials and design concepts. For instance, lightweight alloys and composites, when processed with precision CNC milling, result in components that are both robust and weight-optimized. At CNCRUSH, our state-of-the-art CNC machining service combines deep industry expertise with the latest machining technology to produce CNC Milled parts that are indispensable in aerospace. Our innovations contribute to improvements in fuel efficiency, performance, and overall safety, reinforcing our commitment to the future of aerospace manufacturing.

3. CNC Machining Service: Enhancing Aerospace Performance with CNC Turned Parts

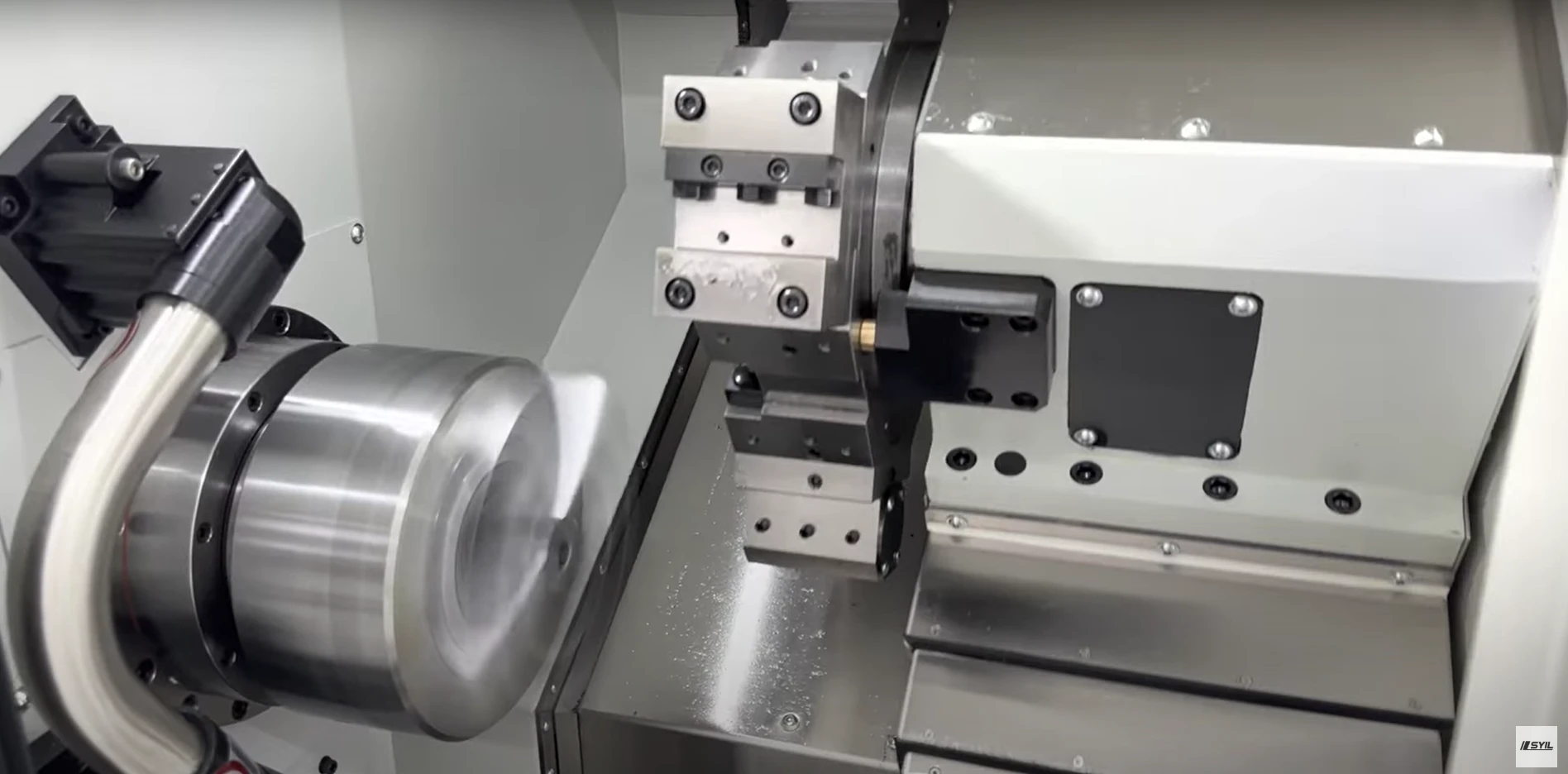

In aerospace manufacturing, CNC Machining isn’t limited to milling operations alone. CNC Turned parts also play a crucial role, particularly in producing components such as shafts, bushings, and other rotationally symmetric parts. These parts require precise turning processes to ensure smooth surfaces and dimensional accuracy.

CNC Turned parts are critical in high-stress applications where consistent performance is required over long operational periods. Advanced turning techniques allow manufacturers to achieve excellent surface finishes and tight tolerances, ensuring that every component can handle extreme environmental conditions. At CNCRUSH, we leverage our 12 years of experience in delivering high-quality CNC Turned parts to meet the stringent demands of aerospace applications. Our comprehensive CNC machining service is designed to provide aerospace manufacturers with components that excel in durability, reliability, and performance.

4. CNC Machining Service: Driving Precision and Efficiency in Aerospace Production

The aerospace sector is synonymous with high standards of precision and efficiency, both of which are hallmarks of modern CNC Machining. Advanced machining technologies have dramatically reduced production lead times and increased part consistency. By employing sophisticated software and automation, manufacturers can optimize machining parameters in real time, ensuring that each component is produced to exact specifications.

A key advantage of CNC machining in aerospace is the ability to quickly adapt to design changes. Digital twin technology and simulation tools allow engineers to test various machining strategies before actual production, saving both time and resources. CNCRUSH harnesses these innovations within our CNC machining service to deliver high-quality CNC Milled parts and CNC Turned parts, tailored for industries such as automotive, machine building, and automotion. Our focus on precision CNC machining ensures that each aerospace component not only meets but often exceeds industry standards.

5. CNC Machining Service: Advanced Technologies in CNC Machining for Aerospace

Cutting-edge technologies are reshaping the landscape of CNC Machining for aerospace manufacturing. From real-time monitoring systems to artificial intelligence-driven optimizations, these advancements are setting new benchmarks in production quality and efficiency. Machine learning algorithms analyze vast datasets from every machining cycle to predict tool wear, optimize cutting speeds, and ensure consistent quality.

Innovations like additive manufacturing integration with subtractive CNC processes are also emerging. These hybrid manufacturing methods allow for the production of components with complex internal geometries that would be impossible to achieve using traditional methods alone. At CNCRUSH, we are constantly investing in advanced technology to stay ahead of industry trends. Our CNC machining service leverages these innovations to produce high-precision CNC Milled parts and CNC Turned parts, ensuring that our clients receive aerospace components that are not only innovative but also highly reliable.

6. CNC Machining Service: Impact on Material Properties and Component Integrity in Aerospace

One of the greatest challenges in aerospace manufacturing is balancing the need for lightweight components with the demand for high strength and durability. CNC Machining plays a critical role in achieving this balance by allowing precise control over material removal processes. Through optimized cutting parameters, manufacturers can enhance the mechanical properties of components while minimizing material waste.

The advanced control offered by CNC machining ensures that each aerospace part has uniform properties, which is essential for ensuring component integrity during operation. Here’s a comparative table that illustrates how different materials perform when processed with CNC machining:

| Material | Weight Reduction Potential | Machining Precision | Application Suitability |

|---|---|---|---|

| Titanium Alloys | High | Excellent | Engine components, airframes |

| Aluminum Alloys | Very High | Very Good | Structural parts, fasteners |

| Composite Materials | High | Good | Fuselage panels, interior components |

| Stainless Steel | Moderate | Excellent | Landing gear, control systems |

This table highlights the advantages of utilizing CNC machining service in processing various aerospace materials. CNCRUSH’s expertise ensures that whether producing CNC Milled parts or CNC Turned parts, the integrity and performance of each component are maximized, meeting the highest industry standards.

7. CNC Machining Service: Future Innovations and Trends in Aerospace Manufacturing

Looking ahead, the future of aerospace manufacturing is intrinsically linked to the evolution of CNC Machining. Emerging trends such as smart manufacturing, the Internet of Things (IoT), and Industry 4.0 are poised to transform how aerospace components are designed, produced, and maintained. Digitalization enables the integration of real-time data analytics with CNC machining processes, leading to smarter decision-making and predictive maintenance.

Future innovations will likely include further integration of AI-driven process controls, allowing machines to self-optimize and adapt to variable production demands. These trends not only enhance production efficiency but also improve the sustainability of aerospace manufacturing by reducing waste and energy consumption. CNCRUSH is at the cutting edge of these developments, continually updating our CNC machining service capabilities to incorporate the latest technologies. Our proactive approach ensures that we remain a trusted partner for aerospace manufacturers seeking custom CNC solutions that deliver high-quality CNC Milled parts and CNC Turned parts.

8. CNC Machining Service: Overcoming Challenges in Aerospace Manufacturing

Despite its many advantages, aerospace manufacturing faces significant challenges that require advanced solutions. One major challenge is ensuring the consistency of high-precision parts amid complex geometries and demanding performance requirements. CNC Machining addresses these challenges by offering unparalleled accuracy and repeatability in every production cycle.

Other challenges include managing material stress, controlling thermal deformation, and maintaining tight tolerances. By leveraging sophisticated simulation software and real-time monitoring systems, manufacturers can anticipate potential issues and adjust parameters accordingly. At CNCRUSH, our extensive experience in CNC machining service enables us to tackle these challenges head-on. We produce CNC Milled parts and CNC Turned parts that meet the most rigorous aerospace standards, ensuring that our clients receive components that are both robust and reliable—even in the most demanding applications.

Below is a table summarizing common challenges in aerospace machining and the corresponding CNC solutions:

| Challenge | CNC Machining Solution | Benefits |

|---|---|---|

| Tight Tolerances | High-precision CNC machining with real-time adjustments | Consistent quality, reduced rework |

| Material Stress and Fatigue | Optimized cutting parameters and cooling systems | Enhanced component durability |

| Thermal Deformation | Advanced toolpath strategies and controlled cutting speeds | Improved dimensional accuracy |

| Complex Geometries | Multi-axis CNC machines and hybrid manufacturing techniques | Ability to produce intricate designs |

This analysis demonstrates how CNC machining service providers like CNCRUSH are equipped to overcome the unique challenges of aerospace manufacturing, ensuring every part is produced to the highest standards.

9. CNC Machining in Aerospace: Integrating Automation in Automotive, Machine Building and Automotion

Beyond aerospace, CNC Machining is a key technology in sectors such as automotive, machine building, and automotion. The precision and repeatability of CNC machining enable manufacturers to produce complex components across these industries, often with shared technology and process innovations. Aerospace manufacturers benefit from cross-industry advancements, as techniques developed in automotive or machine building are frequently adapted for aerospace applications.

Automation is a critical element in this integration. Automated systems enable faster production cycles and reduce the potential for human error, ensuring that every part—whether an aerospace component or an automotive part—meets stringent quality criteria. CNCRUSH’s CNC machining service is designed to serve multiple industries, with specialized processes for producing high-quality CNC Milled parts and CNC Turned parts. Our experience in automotive, machine building, and automotion sectors further enriches our expertise, making us a versatile partner in the global manufacturing landscape.

10. CNC Machining Service: Why CNCRUSH is Your Ideal Partner for Aerospace Manufacturing Excellence

Choosing the right CNC precision machining service provider is critical for success in the aerospace industry. With over 12 years of experience, CNCRUSH stands out as a trusted China CNC factory dedicated to delivering precision CNC precision machining services. Our expertise in producing both CNC Milled parts and CNC Turned parts ensures that aerospace manufacturers receive components that meet rigorous quality and performance standards.

At CNCRUSH, we combine advanced machining technology with a deep understanding of aerospace requirements. Our facility is equipped with the latest CNC machining equipment, and our team of experts is committed to continuous improvement and innovation. We serve diverse industries, including automotive, machine building, and automotion, which allows us to apply cross-industry best practices to aerospace projects. When you choose CNCRUSH, you are partnering with a company that values precision, reliability, and customer satisfaction above all.

Our commitment to excellence in CNC precision machining has earned us a reputation as one of the leading custom CNC parts manufacturers in China. Whether you require CNC Milled parts or CNC Turned parts, our high-quality CNC machining services are tailored to meet your specific needs. We invite you to visit our website at https://cncrush.com/ to learn more about our capabilities and discover why we are the ideal partner for aerospace manufacturing innovation.

FAQ Section

Q1: What is CNC Machining and why is it essential in aerospace manufacturing?

A: CNC Machining is a computer-controlled manufacturing process used to create high-precision parts. In aerospace manufacturing, it ensures consistent quality, reduced production time, and the ability to produce complex geometries with tight tolerances.

Q2: How do CNC Milled parts contribute to aerospace innovation?

A: CNC Milled parts are crucial for producing lightweight, strong, and precisely engineered components. Their complex designs and high-quality finishes make them ideal for critical aerospace applications where performance and reliability are paramount.

Q3: What role do CNC Turned parts play in aerospace manufacturing?

A: CNC Turned parts, such as shafts and cylindrical components, are manufactured with exceptional precision. They offer smooth surface finishes and consistent dimensions, ensuring optimal performance in high-stress aerospace environments.

Q4: How does CNCRUSH ensure the quality of its aerospace components?

A: With over 12 years of experience, CNCRUSH employs advanced CNC precision machining service techniques, real-time process monitoring, and cutting-edge technology to produce high-quality CNC Milled parts and CNC Turned parts that meet stringent aerospace standards.

Q5: Can CNC Machining reduce production costs in aerospace manufacturing?

A: Yes, optimized CNC Machining not only improves product quality but also enhances production efficiency by reducing cycle times and minimizing waste, ultimately lowering overall production costs.

Conclusion

CNC Machining is undeniably shaping the future of aerospace manufacturing by enabling unprecedented levels of precision, efficiency, and innovation. From the production of intricate CNC Milled parts and CNC Turned parts to the integration of advanced automation and smart manufacturing technologies, the aerospace industry is experiencing a paradigm shift. In this article, we explored 10 breakthrough areas—from the role of CNC precision machining service in transforming manufacturing processes to the challenges and future trends that are defining the industry.

The analysis shows that CNC Machining is not just about cutting and shaping materials; it is a dynamic process that drives innovation across sectors such as aerospace, automotive, machine building, and automotion. By leveraging digital technologies, real-time analytics, and cutting-edge machinery, manufacturers can produce components that meet the rigorous demands of modern aerospace applications.

At CNCRUSH, our passion for excellence and our commitment to precision have made us a leader in the CNC precision machining service sector. With over 12 years of experience, we have honed our processes to deliver top-quality CNC Milled parts and CNC Turned parts that serve critical applications in aerospace and beyond. Our continuous investment in advanced technology and skilled engineering ensures that our clients receive products that not only meet but often exceed industry standards.

The future of aerospace manufacturing is bright, with CNC Machining playing a central role in driving innovation and efficiency. As new materials and processes evolve, the ability to adapt and optimize will be paramount. Manufacturers that embrace these advancements will benefit from improved performance, reduced costs, and enhanced sustainability.

We invite you to explore our extensive range of services at CNCRUSH. Whether you require precision CNC precision machining services for aerospace components or custom CNC solutions tailored to your specific needs, CNCRUSH is your ideal partner for innovation and excellence. With our proven track record, state-of-the-art facilities, and dedication to quality, we are ready to help you navigate the challenges and seize the opportunities of modern aerospace manufacturing.