Custom CNC solutions have become essential in modern industries where precision, efficiency, and repeatability are crucial. As a specialized CNC machining service provider based in China, CNCRUSH has been serving the global market for over 12 years, delivering CNC Milled parts and CNC Turned parts to a variety of industries. The role of CNC machining extends beyond just cutting materials; it offers a refined, automated process that enhances production quality and reduces human error.

Drawing inspiration from global leaders such as Anttrom, GMI Corp, and Petersen Precision, this article explores how custom CNC solutions can transform industries, focusing on the automotive, machine building, and automation sectors. We will delve into how precise CNC machining can boost productivity, ensure tight tolerances, and provide material versatility to meet the stringent demands of global clients.

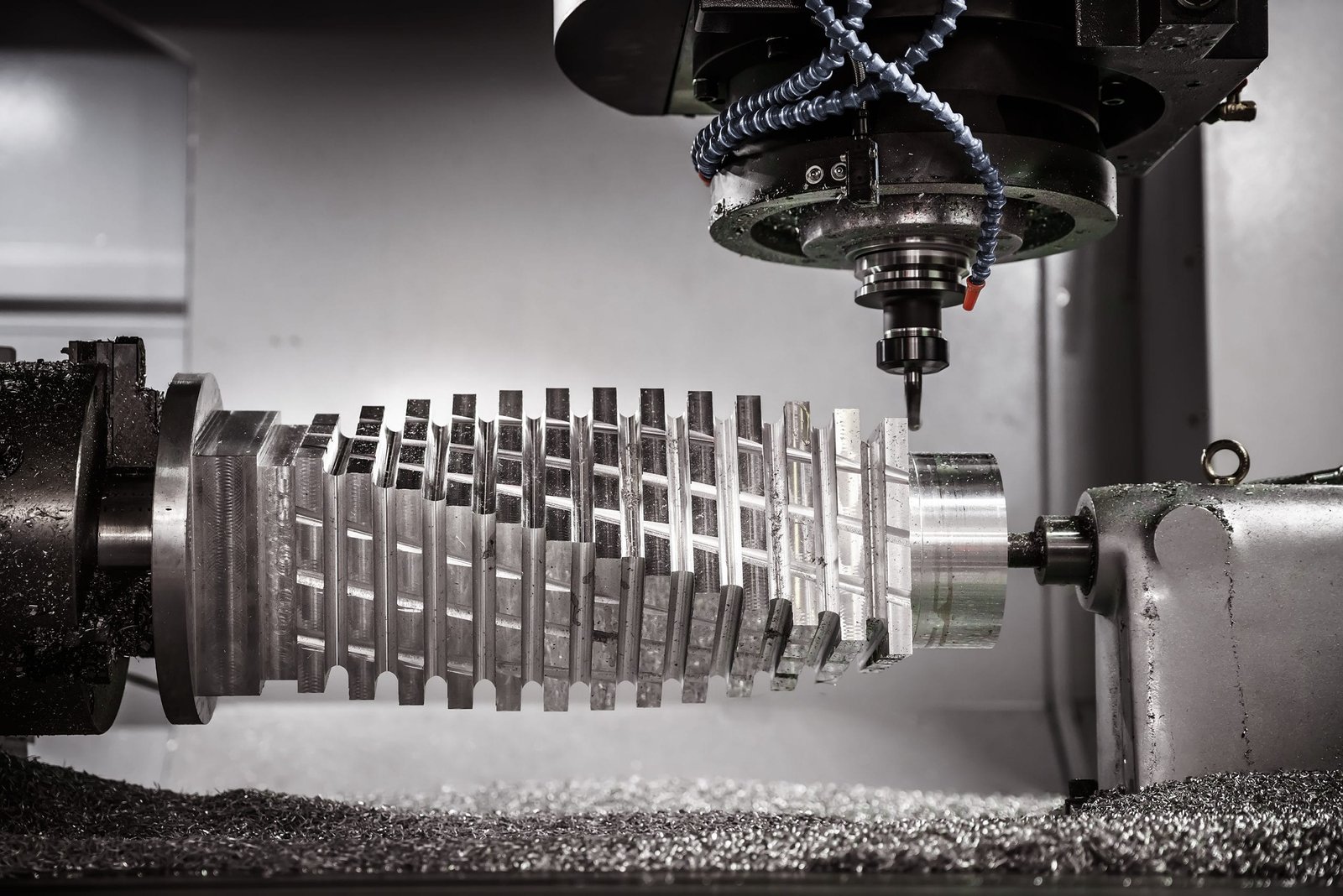

The Rise of CNC Machining in Precision Manufacturing

The adoption of CNC machining has revolutionized industries, particularly in sectors that require high precision. Anttrom, for example, provides robust solutions using advanced CNC technologies, ensuring that large production orders meet strict specifications. Similarly, GMI Corp boasts over 35 years of experience in turning parts from challenging metals, emphasizing the importance of tight tolerances. In contrast, Petersen Precision focuses on high-volume machining with lights-out capabilities, further emphasizing the scalability of CNC operations.

At CNCRUSH, we take pride in delivering Custom CNC Solutions that cater to small- to medium-batch production with precision and efficiency. We have seen first-hand how CNC machining is not just about removing material; it’s about delivering a finished product that can withstand rigorous industry standards.

1. What are Custom CNC Solutions?

Custom CNC solutions refer to bespoke CNC machining services designed to meet specific client needs. The key lies in customization and precision. For instance, Anttrom focuses on machining for various materials like aluminum, steel, and plastics, with competitive pricing and ISO-certified quality control. This allows manufacturers to benefit from repeatable, high-quality parts that reduce lead times and costs.

At CNCRUSH, our team specializes in CNC Milled parts and CNC Turned parts, offering custom solutions for a range of industries, from automotive to automation. With over 12 years of experience, our custom CNC solutions ensure that we can handle complex geometries and tough tolerances, particularly in high-demand environments.

2. The Importance of Precision in CNC Machining

Precision is the core of any CNC machining process. Without precise control over material removal and dimensions, manufacturers risk producing parts that are out of tolerance, leading to poor assembly performance. For example, Petersen Precision uses advanced multi-axis CNC technology that allows for tolerances as tight as ±0.0005” for medical and aerospace parts.

At CNCRUSH, we ensure our Custom CNC Solutions aligns with the highest standards by utilizing state-of-the-art equipment that allows us to maintain tight tolerances across a variety of materials such as stainless steel, aluminum, and brass. Whether producing CNC Milled parts or CNC Turned parts, maintaining these tight tolerances means ensuring the reliability and performance of your final product.

3. Custom CNC Solutions for the Automotive Industry

The automotive industry demands precision parts that can withstand mechanical stresses. Modern Group is an example of a company that produces high-volume CNC parts for industries like automotive and power sports, demonstrating how CNC machining meets the demand for scalable production.

CNCRUSH works closely with automotive manufacturers to produce high-precision CNC Turned parts for components like gears, brackets, and steering mechanisms. By leveraging multi-axis CNC machinery, we can provide parts with tight tolerances that improve performance and safety in automotive applications.

4. Versatility of CNC Machining in Materials

One of the significant advantages of CNC machining is its versatility in handling different materials. From soft plastics to hardened steels, CNC technology can process a vast array of materials, allowing manufacturers to tailor parts to their specific needs.

For example, Metal Cutting Corporation specializes in high-precision CNC machining of titanium and other exotic metals, which require precise handling due to their material properties. At CNCRUSH, we offer machining services for aluminum, steel, brass, plastic, and exotic alloys, ensuring that your components meet the material standards required for your industry.

5. Why Custom CNC Solutions are Cost-Effective

CNC machining can be expensive due to the complexity of the machines involved, but the benefits far outweigh the costs. Anttrom and GMI Corp demonstrate how CNC machining solutions not only increase production speed but also reduce waste and labor costs by automating complex manufacturing tasks.

At CNCRUSH, our cost-effective solutions come from maximizing material usage and reducing manual interventions. By automating processes such as milling, turning, and drilling, we can lower overall production costs while maintaining high precision and quality.

6. Surface Finishes in CNC Machining

Surface finishing is another critical aspect of CNC machining that often gets overlooked. Many industries require parts with specific surface qualities, whether for aesthetic reasons or functional benefits like corrosion resistance. For instance, Anttrom offers a wide range of surface finishes, including anodizing, powder coating, and zinc plating.

At CNCRUSH, we ensure that your CNC Milled parts and CNC Turned parts can be finished to your exact specifications, whether you require a polished finish or a durable coating to protect against wear and tear in harsh environments.

7. Scalability in CNC Production

Custom CNC Solutions allows for both prototyping and high-volume production. Petersen Precision and Modern Group both emphasize the scalability of their services, offering the capability to produce thousands of parts with consistent quality.

At CNCRUSH, we offer scalable Custom CNC Solutions, whether you need a single prototype or a full production run. Our machines are capable of lights-out production, which enables us to meet even the most demanding production schedules.

8. Key Industries Benefiting from CNC Machining

Many industries, such as automotive, medical, and aerospace, heavily rely on CNC machining due to the precise nature of the parts required. For example, Metal Cutting Corporation focuses on small metal parts for medical devices, while Modern Group serves a broader array of industries like aerospace and defense.

CNCRUSH provides CNC solutions for industries like machine building, automotive, and automation, ensuring that our clients receive parts that meet the highest quality standards.

9. Challenges and Solutions in CNC Machining

Working with tough metals and challenging geometries is one of the most significant challenges in CNC machining. Both GMI Corp and Metal Cutting Corporation highlight their expertise in handling difficult materials such as titanium and Inconel.

At CNCRUSH, we are no strangers to these challenges. Our experienced machinists are equipped to tackle complex jobs using advanced CNC equipment, ensuring that even the most difficult designs are executed to perfection.

10. The Future of CNC Machining Services

The future of CNC machining lies in its ability to integrate with advanced technologies such as AI and IoT. Companies like Petersen Precision and Modern Group are already implementing lights-out production techniques, where machines can operate with minimal human intervention.

CNCRUSH is at the forefront of adopting such technologies to enhance our Custom CNC Solutions. As we continue to evolve, our focus remains on providing custom solutions that meet the growing demands of industries worldwide.

Material Capabilities at CNCRUSH

| Material Type | Applications | Tolerances |

|---|---|---|

| Aluminum | Aerospace, Automotive | ±0.005 mm |

| Stainless Steel | Medical, Industrial | ±0.01 mm |

| Brass | Electronics, Plumbing | ±0.02 mm |

| Plastic | Consumer Goods, Automation | ±0.05 mm |

Custom CNC Solutions at CNCRUSH

| Service Type | Process | Industries Served |

|---|---|---|

| CNC Milling | Multi-Axis Milling | Automotive, Aerospace |

| CNC Turning | Precision Turning | Machine Building, Automation |

| Prototyping | Rapid Prototyping | Medical, Consumer Electronics |

FAQ

1. What types of CNC services does CNCRUSH offer?

CNCRUSH offers a wide range of Custom CNC Solutions, including CNC milling, CNC turning, and rapid prototyping.

2. Can you handle small and large production runs?

Yes, we specialize in both small-batch production and high-volume orders, depending on your needs.

3. What industries do you serve?

We serve industries such as automotive, machine building, automation, and more.

4. What materials do you work with?

We work with a wide variety of materials, including aluminum, steel, brass, and plastic.

By leveraging the power of custom CNC solutions, CNCRUSH continues to deliver exceptional value to its global clientele.