Electrochemical polishing, also known as electropolishing, is a crucial process for enhancing the surface finish, cleanliness, and corrosion resistance of aluminum and other metals. This anodic process involves using an electric current and a chemical electrolyte to remove a thin layer from the metal surface, resulting in a highly reflective, smooth finish. This article delves into the mechanisms, benefits, and applications of electropolishing aluminum, offering insights into the latest advancements and practical considerations for industries such as automotive, machine building, and automation.

At CNCRUSH, we provide CNC machining services with over 12 years of experience, specializing in CNC milled parts and CNC turned parts. Our expertise in precision machining, combined with our knowledge of advanced surface treatments such as electropolishing, enables us to deliver superior results for clients across various industries. Whether you’re looking for high-quality surface finishes for aluminum components or seeking custom machining solutions, CNCRUSH is your trusted partner.

1. What is Electrochemical Polishing of Aluminum?

Electrochemical polishing is a finishing process that smooths and polishes metal surfaces by dissolving microscopic layers of material from the workpiece. This is achieved by placing the aluminum part (anode) in an electrolyte bath and applying an electrical current between it and a cathode. The peaks on the aluminum surface are preferentially dissolved, resulting in a smoother and more reflective surface.

Unlike mechanical polishing methods such as grinding or buffing, electropolishing offers a more uniform surface, free from tool marks. It is especially effective for complex geometries and small parts, where traditional mechanical techniques would be inefficient.

2. Key Benefits of Electropolishing Aluminum

The benefits of electropolishing aluminum extend beyond aesthetics, making it a valuable process for industries requiring high-performance, smooth surfaces. These advantages include:

- Improved Corrosion Resistance: By removing surface impurities and creating a smooth finish, electropolishing enhances aluminum’s natural resistance to corrosion.

- Reduced Friction: The process eliminates microscopic surface peaks, leading to less friction in moving parts, crucial for automotive and machine building applications.

- Deburring and Cleaning: Electropolishing is highly effective in removing burrs and microscopic contaminants, leaving a clean and sterile surface ideal for industries such as electronics and medical devices.

- Enhanced Aesthetics: A mirror-like finish improves the visual appeal of aluminum parts, making it suitable for decorative components in automotive and consumer products.

- Increased Durability: Removing surface stresses during electropolishing increases the durability of aluminum components, prolonging their operational life.

3. Applications of Electropolishing in CNC Machining Services

Electropolishing is highly versatile and can be applied to various industries that require precision in surface finishing. Some key applications include:

- Automotive Components: Electropolished aluminum parts, such as rims and engine components, benefit from improved aesthetics, reduced friction, and enhanced durability.

- Machine Building and Automation: For CNC milled parts and CNC turned parts in automated systems, electropolishing reduces wear and tear, extending the lifespan of machinery.

- Medical Devices: The ultra-clean, smooth finish achieved through electropolishing is ideal for medical tools and implants, as it ensures biocompatibility and prevents bacterial growth.

- Electronics: Aluminum housings and components in electronics gain from electropolishing’s ability to improve heat dissipation and provide a flawless appearance.

4. How Electropolishing Works: The Technical Process

The electropolishing process for aluminum involves several critical steps:

- Preparation: The aluminum part is cleaned to remove any contaminants, oils, or grease that could interfere with the uniformity of the electric current.

- Electropolishing Bath: The aluminum piece is immersed in an electrolyte solution (typically sulfuric or phosphoric acid) and connected to a positive charge. The cathode, often made from stainless steel, completes the circuit.

- Electric Current Application: The electric current dissolves material from the aluminum surface, with higher current densities targeting the peaks and rough areas first. This results in a microscopically smooth surface.

- Post-Processing: After electropolishing, the part is rinsed and neutralized to remove any residual acid or by-products from the process.

5. Green Advancements in Electrochemical Polishing: Reducing Environmental Impact

Traditional electropolishing methods often involve hazardous chemicals such as perchloric acid, which pose significant environmental and safety concerns. However, recent advancements have introduced more eco-friendly alternatives, such as deep eutectic solvents (DES) made from choline chloride and propylene glycol. These green solvents provide comparable results to traditional methods but without the environmental risks associated with toxic chemicals.

| Traditional Method | Green Alternative (DES) |

|---|---|

| Uses perchloric acid (hazardous) | Uses choline chloride (safe) |

| High temperatures required | Room temperature process |

| Waste disposal challenges | Environmentally friendly solvent |

6. Electrochemical Polishing vs. Mechanical Polishing: Key Differences

While mechanical polishing methods like grinding and buffing are commonly used, electropolishing offers distinct advantages, especially for intricate parts. Key differences include:

- Surface Uniformity: Electrochemical Polishing achieves a more uniform finish, free from tool marks or scratches commonly left by mechanical polishing.

- Complex Geometries: Electrochemical Polishing can easily handle complex shapes and small features that are difficult to access with mechanical tools.

- Stress-Free Processing: Unlike mechanical methods that can introduce surface stresses, Electrochemical Polishing avoids deformation, making it ideal for delicate parts.

7. The Role of CNC Machining in Preparing Aluminum for Electrochemical Polishing

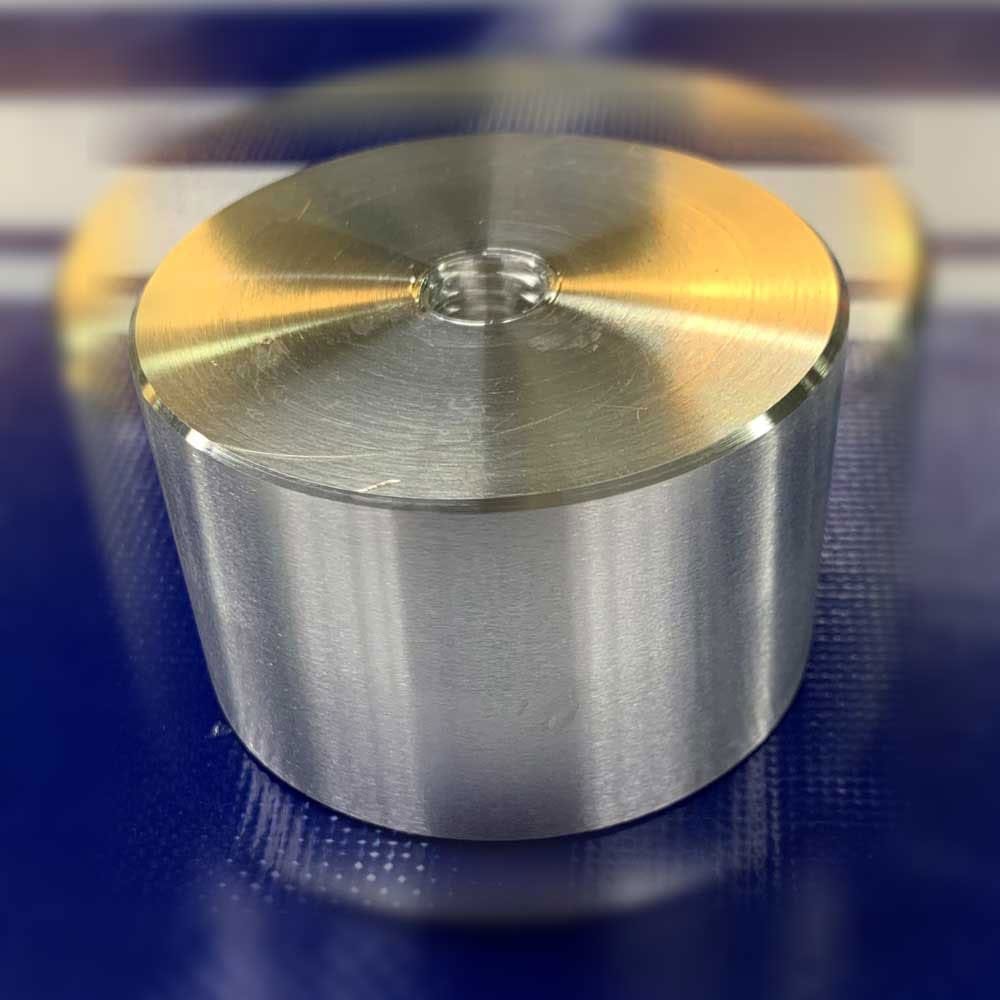

Before aluminum parts undergo electropolishing, CNC machining plays a vital role in shaping and preparing the material. Precise CNC milled parts and CNC turned parts from CNCRUSH ensure that the surfaces are ready for polishing, with minimal defects or irregularities. By combining advanced CNC techniques with electropolishing, CNCRUSH delivers high-quality components that meet the stringent demands of industries like automotive and automation.

8. Electrochemical Polishing Challenges: Common Issues and Solutions

While electropolishing is an effective process, it is not without its challenges. Common issues include:

- Hydrogen Bubbles: The generation of hydrogen gas during electropolishing can lead to streaks or defects on the aluminum surface. Reducing current density or adjusting the fixture can help alleviate this problem.

- Sludge Accumulation: The electrolyte can produce sludge that, if not removed, can reduce the efficiency of the process. Regular cleaning and electrolyte maintenance are essential to avoid this issue.

9. Electrochemical Polishing for Aluminum: Cost Considerations

Electropolishing can add value to aluminum components, but it also introduces additional costs related to equipment, chemicals, and processing time. However, for applications requiring high-performance finishes, such as in the automotive or electronics industries, the benefits of reduced friction, improved durability, and enhanced aesthetics often outweigh the costs.

CNCRUSH offers competitive pricing for CNC machining services, including options for electropolishing, ensuring that our clients receive cost-effective solutions without compromising on quality.

10. Conclusion: Why Choose CNCRUSH for CNC Machining and Electrochemical Polishing

At CNCRUSH, we understand the importance of precision and surface quality in industries like automotive, machine building, and automation. Our CNC machining services are backed by over a decade of experience, and we specialize in providing custom solutions that include CNC milled parts, CNC turned parts, and advanced surface treatments like electropolishing.

If you’re looking to improve the performance and appearance of your aluminum components, contact CNCRUSH for expert CNC machining services that combine the latest technology with superior craftsmanship.

FAQ Section

Q1: What types of aluminum can be electropolished?

Most aluminum alloys, including 6061 and 7075, can be electropolished, although certain cast aluminum alloys may not yield as smooth results.

Q2: Is electropolishing eco-friendly?

New advancements in electropolishing, such as the use of deep eutectic solvents (DES), provide more environmentally friendly alternatives to traditional acid-based solutions.

Q3: How much material is typically removed during Electrochemical Polishing?

Electropolishing typically removes between 0.0003 to 0.0007 inches of material, depending on the duration and intensity of the process.

Q4: Can Electrochemical Polishing replace mechanical polishing?

For applications requiring high precision, smooth finishes, and corrosion resistance, electropolishing is often superior to mechanical polishing methods.

Q5: What industries benefit the most from electropolished aluminum parts?

Industries such as automotive, medical devices, electronics, and machine building benefit significantly from the performance and aesthetic improvements provided by electropolishing.

For more information on CNC machining services or to discuss your specific aluminum electropolishing needs, visit CNCRUSH.

This design is wicked! You certainly know how to keep a reader entertained. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Fantastic job. I really loved what you had to say, and more than that, how you presented it. Too cool!