Machined parts are vital to the automotive industry, contributing significantly to vehicle precision, performance, and innovation. CNC machining, known for its accuracy, speed, and adaptability, has transformed the production of automotive parts, ensuring high-quality outputs with minimal waste. From engine components to custom modifications, the role of CNC machining is indispensable in modern automotive manufacturing.

At CNCRUSH, with over 12 years of experience, we specialize in producing high-precision CNC Milled parts and CNC Turned parts for industries like automotive, machine building, and automation. Our comprehensive CNC machining service offers unparalleled quality and flexibility to help manufacturers meet their production demands efficiently.

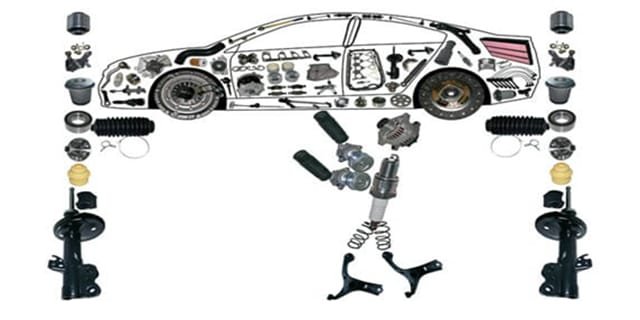

1. The Critical Role of Machined Parts in the Automotive Industry

Automotive components demand extreme precision, as even minor deviations can significantly impact performance, safety, and durability. Machined parts, especially those made through CNC technology, offer the high degree of accuracy required for engine components, transmission gears, brake systems, and other essential parts.

At CNCRUSH, we take pride in delivering custom CNC solutions that meet the stringent requirements of the automotive sector. Our CNC machining services are designed to cater to large production runs as well as custom one-off projects.

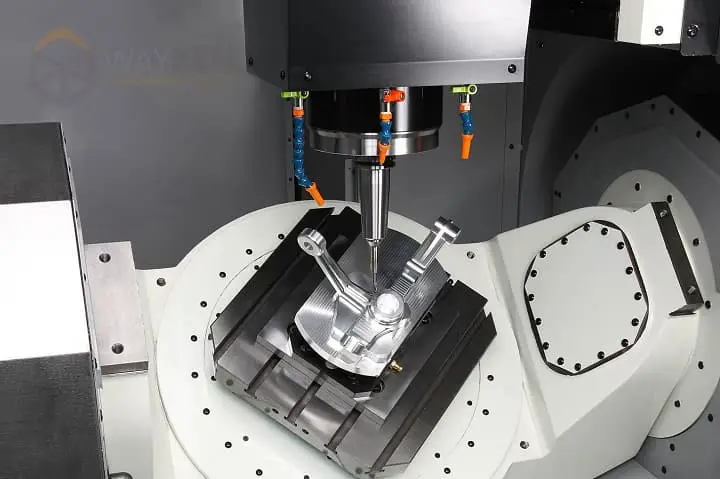

2. Precision and Accuracy: The Cornerstone of CNC Machining for Automotive Parts

Precision is paramount when manufacturing automotive parts, from engine blocks to braking systems. CNC machining services enable us to achieve tight tolerances, typically within ±0.005 mm, ensuring that each part fits seamlessly within the assembly. This is particularly important for high-performance applications, such as turbochargers or piston systems.

At CNCRUSH, we leverage cutting-edge CNC milling and turning technologies to ensure CNC Machined Parts meet the highest precision standards, allowing our clients to reduce errors and optimize performance.

3. How CNC Milling and Turning Meet Automotive Industry Needs

The automotive industry requires parts that are not only precise but also durable and resistant to wear. CNC milling and turning processes are highly efficient in producing complex shapes and achieving the necessary surface finishes. Whether you’re machining engine components or creating custom parts for high-performance vehicles, CNC machining ensures the consistency and strength of each part.

Our CNC Machined Parts at CNCRUSH specializes in both CNC Milled parts and CNC Turned parts, providing flexibility and precision to match the specific needs of the automotive market.

4. Applications of CNC Machining in Automotive Manufacturing

CNC Machined Parts plays a critical role in producing various automotive components. These include engine parts, transmission systems, braking systems, and suspension components. CNC machines can create intricate and robust parts like crankshafts, camshafts, pistons, and brake calipers with minimal material waste, ensuring both cost-effectiveness and durability.

At CNCRUSH, we specialize in CNC Machined Parts, including CNC machining aluminum, steel, brass, and plastics for various automotive applications.

Table 1: Key Automotive Parts Produced Using CNC Machining

| Automotive Component | Material | Production Method |

|---|---|---|

| Engine Blocks | Aluminum, Steel | CNC Milling |

| Brake Calipers | Aluminum, Brass | CNC Turning |

| Transmission Gears | Steel, Titanium | CNC Milling |

| Suspension Components | Aluminum, Steel | CNC Milling/Turning |

5. CNC Prototyping: Driving Innovation in the Automotive Industry

Prototyping is an essential phase in the automotive industry, allowing engineers to test designs before committing to large-scale production. CNC Machined Parts is highly valued for its ability to quickly produce prototypes that are identical to the final product, enabling faster innovation and shorter development cycles.

CNCRUSH offers CNC prototype machining services to help manufacturers test and refine their designs before scaling up for mass production.

6. Cost-Effectiveness and Material Efficiency

CNC machining not only guarantees high precision but also offers excellent material efficiency, making it a cost-effective solution for automotive manufacturing. By minimizing waste and reducing the need for reworks, CNC machines help manufacturers lower overall production costs.

Our CNC Machined Parts at CNCRUSH optimizes material usage, ensuring that each project—whether it’s CNC machining for metal parts or plastic parts—is cost-effective while maintaining superior quality.

7. Customization in CNC Machining: Meeting the Automotive Industry’s Unique Demands

The automotive industry constantly evolves, with custom designs and innovations driving the market. CNC machining offers unrivaled flexibility, allowing manufacturers to easily adapt designs, whether it’s for new performance features or aesthetic enhancements.

At CNCRUSH, we offer custom CNC solutions for manufacturers needing specialized, one-of-a-kind components. Our extensive experience in CNC machining in China allows us to meet both standard and customized automotive demands.

8. CNC Turned Parts: Ensuring Smooth Power Transmission and Efficiency

Transmission systems, one of the most vital aspects of a vehicle’s performance, require components that are produced with extreme precision. CNC Machined Parts, such as gears, shafts, and clutch components, ensure that power is transferred efficiently through the vehicle’s drivetrain, reducing friction and increasing reliability.

CNCRUSH excels in producing CNC Machined Parts that are critical to the smooth functioning of transmission systems, helping manufacturers ensure that their vehicles deliver optimal performance.

9. CNC Machining and Automation: The Future of Automotive Manufacturing

With the rise of automation in manufacturing, CNC machining plays a crucial role in reducing lead times and increasing production capacity. In the automotive industry, where mass production meets customization, CNC machines enable manufacturers to switch between tasks efficiently without sacrificing quality or precision.

At CNCRUSH, our automated CNC machining services integrate seamlessly into the production lines of automotive manufacturers, offering solutions that are both scalable and reliable.

Table 2: CNC Machining for Automation Components

| Automation Component | Material | Machining Method |

|---|---|---|

| Gear Systems | Steel, Aluminum | CNC Turning |

| Engine Sensors | Plastic, Brass | CNC Milling |

| Electric Motor Housings | Aluminum, Steel | CNC Milling/Turning |

10. CNC Machined Parts for Electric Vehicles (EVs)

As the automotive industry transitions toward electric vehicles (EVs), the demand for lightweight and high-strength components increases. CNC machining is pivotal in producing the intricate parts required for EVs, such as electric motor housings, battery enclosures, and complex heat dissipation systems.

At CNCRUSH, we are adapting our CNC machining services to meet the specific needs of the automotive EV sector, ensuring high precision and quality for critical components in electric vehicles.

FAQ Section

Q1: What is CNC machining and how is it used in automotive manufacturing?

CNC machining is a computer-controlled manufacturing process that produces parts with high precision. In automotive manufacturing, it is used to create engine components, transmission systems, and other critical parts.

Q2: What materials can be used in CNC machining for automotive parts?

Common materials include aluminum, steel, titanium, brass, and plastics. At CNCRUSH, we specialize in CNC Machined Parts for the automotive industry.

Q3: How does CNC machining improve the performance of automotive components?

CNC machining ensures that parts are produced with extreme accuracy, leading to better fit, reduced wear, and enhanced overall performance of automotive components.

Conclusion

Machined parts are fundamental to the success of modern automotive manufacturing, providing the precision, efficiency, and flexibility needed to meet the industry’s demanding standards. Whether it’s producing prototypes or scaling up for mass production, CNC machining services are essential for driving innovation and performance in the automotive sector.

At CNCRUSH, our 12 years of experience, coupled with state-of-the-art CNC milling and turning capabilities, make us a trusted partner for CNC Machined Parts and custom CNC solutions. Contact us today to learn how we can support your automotive manufacturing needs!