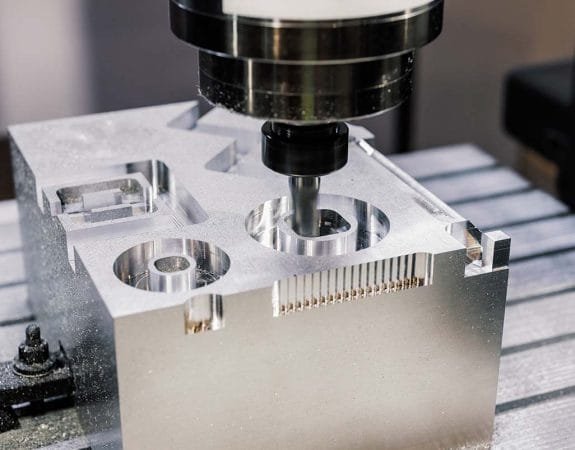

CNC machining plays a pivotal role in the metal parts manufacturing industry. Whether it’s in the automotive, machine building, or automation sectors, the precision and efficiency provided by CNC machining make it indispensable. For manufacturers seeking high-quality, scalable, and cost-effective solutions, understanding the benefits of CNC machining is essential.

1. Precision in Metal Parts Manufacturing

CNC machining offers unmatched precision, which is particularly important for industries that require tight tolerances, such as automotive and machine building. CNC machines can achieve tolerances as small as 0.004 mm, ensuring that each part meets exact specifications.

2. Cost-Effective and Scalable Solutions

For businesses in metal parts manufacturing, CNC machining offers an ideal balance between cost-efficiency and scalability. After initial programming, CNC machines can produce parts autonomously, reducing labor costs and enabling scalability—from prototypes to large production runs.

3. High Production Speed

One of the strongest advantages of CNC machining is its ability to run continuously, 24/7, without interruption. This increases production speed and helps manufacturers meet tight deadlines, a critical advantage for industries such as automation.

4. Versatility in Material Selection

CNC machining is compatible with a wide range of materials, including steel, aluminum, brass, and even non-metallic materials like plastics. This versatility makes CNC machining perfect for creating custom parts for various industries.

| Material | Common Applications |

|---|---|

| Aluminum | Automotive components, aerospace parts |

| Steel | Heavy-duty machine parts, engine components |

| Brass | Electrical connectors, precision fittings |

| Plastics | Custom enclosures, lightweight machine parts |

5. Complex Designs Made Simple

One of the key strengths of CNC machining is its ability to produce highly complex geometries with ease. Whether you’re producing intricate CNC Milled parts or precision CNC Turned parts, CNC machines handle complex designs far better than manual machining.

6. Consistency and Repeatability

CNC machining ensures that each part produced is identical to the last, even across thousands of units. This level of consistency is crucial for manufacturers in automotive and machine building industries, where component accuracy can directly affect product performance and safety.

7. Reduced Waste and Material Efficiency

By optimizing cutting paths and reducing human error, CNC machining minimizes material waste. For manufacturers focused on sustainability and cost-efficiency, this is a significant advantage. Moreover, CNC machining is a subtractive process, allowing precise control over the amount of material removed.

8. Short Lead Times and Fast Prototyping

In the world of metal parts manufacturing, lead times can make or break a project. CNC machining enables rapid prototyping, allowing manufacturers to test and iterate designs quickly, ensuring that the final product is ready for market faster.

9. Low Maintenance and High Reliability

CNC machines require minimal maintenance, making them a reliable choice for high-demand production environments. Unlike traditional machines, CNC tools need only occasional adjustments and tool replacements, allowing production to continue with minimal downtime.

10. Customization and Flexibility

CNC machining offers unparalleled flexibility for custom CNC solutions. Whether you need CNC Milled parts for automotive or CNC Turned parts for machine components, CNC technology provides the capability to produce customized solutions quickly and efficiently.

FAQ: CNC Machining for Metal Parts Manufacturing

Q1: What materials can be used in CNC machining?

A1: CNC machining supports a wide variety of materials, including aluminum, steel, brass, and various plastics.

Q2: How does CNC machining ensure precision?

A2: CNC machines are controlled by pre-programmed software, which eliminates human error, ensuring each part is manufactured with consistent precision.

Q3: Is CNC machining suitable for small production runs?

A3: Yes. CNC machining is highly scalable, making it ideal for both small and large production runs.

Table: CNC Machining Services Comparison

| Service | Key Features | Ideal for |

|---|---|---|

| CNC Milled Parts | High precision, ideal for complex geometries | Automotive, automation |

| CNC Turned Parts | Excellent for cylindrical parts and tight tolerances | Machine building, aerospace |

| Custom CNC Solutions | Tailored solutions for specific industry needs | Automotive, custom machinery |

For high-quality CNC machining services with a focus on precision and efficiency, CNCRUSH offers 12 years of expertise in producing CNC Milled parts and CNC Turned parts. Contact us today for reliable services tailored to your industry needs.