CNC Machining is at the heart of precision manufacturing, and when it comes to pistons—critical components in automotive, machine building, and automation—accuracy and reliability are non-negotiable. From industry case studies to advanced piston turning lathes, expert insights show that achieving flawless pistons requires not just the right equipment but also years of specialized experience. This article summarizes key aspects highlighted by leading resources on piston machining and then dives deeper into 10 essential discussions about piston manufacturing. Along the way, we will also explain why CNCRUSH, a China-based CNC machining factory with 12 years of experience, is a trusted partner for global clients in delivering CNC Milled parts and CNC Turned parts with uncompromising quality.

1. CNC Machining Service for Pistons – Why Accuracy Matters

At the core of piston manufacturing lies CNC machining service, which ensures every micron of tolerance is achieved. Pistons must withstand extreme heat, pressure, and friction in engines, and any dimensional error can lead to catastrophic failure. Studies show that manufacturers who rely on outdated or manual processes face higher rejection rates, leading to financial losses and negative client experiences.

At CNCRUSH, we leverage 5-axis machining centers, precision CMM inspection, and advanced turning lathes to deliver piston prototypes and production runs that meet global standards. Our long-term investment in CNC machining service gives automotive and automation clients confidence that every piston functions as designed.

2. CNC Machining of Pistons – Materials and Their Impact

The choice of material directly influences piston durability. Aluminum alloys such as Ergal 7075 or forged aluminum are widely used for their light weight and heat resistance. Steel pistons, on the other hand, are increasingly applied in heavy-duty engines for their strength.

| Material | Advantages | Applications |

|---|---|---|

| Aluminum Alloys | Lightweight, high thermal conductivity, cost-effective | Automotive cars, motorcycles |

| Steel | High strength, resistance to wear, withstands higher combustion pressure | Heavy trucks, industrial machines |

| Composite Alloys | Balanced performance, customized per client | Specialized racing engines |

With CNC Milled parts and CNC Turned parts, materials must be carefully selected and machined to precise tolerances. CNCRUSH works with aluminum, steel, and plastics, providing a broad range of machining capabilities to meet the specific needs of global clients.

3. CNC Milled Parts for Pistons – From Concept to Execution

CNC Milled parts play a vital role in piston production. Milling allows complex geometries such as grooves, oil holes, and asymmetric crown shapes to be created with micrometer precision. A poorly milled piston may lead to negative outcomes like uneven combustion or increased fuel consumption.

At CNCRUSH, our 3-axis, 4-axis, and 5-axis CNC milling machines can handle everything from prototype to mass production. Our engineering team often advises clients on optimizing designs to reduce costs while maintaining critical tolerances.

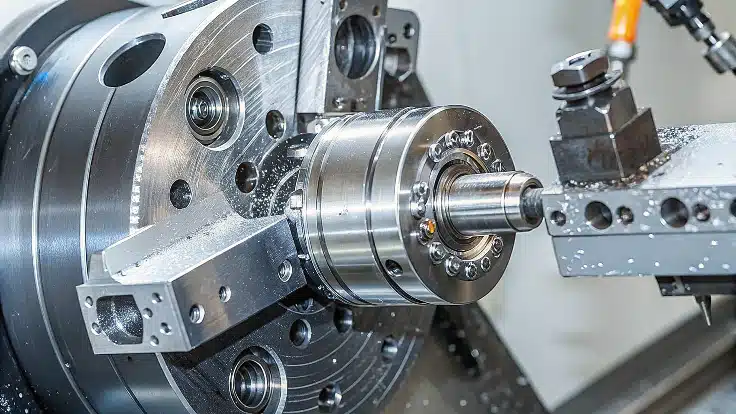

4. CNC Turned Parts in Piston Manufacturing

CNC Turned parts are central in machining the cylindrical geometry of pistons. Turning operations create the piston skirt, pin bores, and grooves with extreme accuracy. Modern piston turning lathes enable higher efficiency and reduced setup times compared to conventional machines.

Our expertise at CNCRUSH ensures that CNC Turned parts not only meet dimensional specifications but also achieve surface finishes below Ra 0.8, improving piston performance and reducing wear.

5. CNC Machining and Surface Finish of Pistons

Surface finish is a positive performance factor in piston machining. A rough finish may cause friction and wear, while a too-smooth finish may limit lubrication film retention. Balancing these factors is critical.

At CNCRUSH, we apply honing, polishing, and coating processes where required. Each piston undergoes strict inspection using height gauges, micrometers, and CMMs. This balance between machining precision and surface quality ensures long-lasting piston performance in both automotive and automation industries.

6. Automation in CNC Machining Service for Pistons

Automation has transformed piston production. Flexible manufacturing systems (FMS), robotic part handling, and AI-driven tool monitoring reduce cycle times and improve consistency.

A comparison of traditional vs automated piston machining:

| Factor | Traditional Machining | Automated CNC Machining Service |

|---|---|---|

| Precision | Operator-dependent | Consistently < ±0.01 mm |

| Efficiency | Slower, higher setup time | Faster, continuous cycles |

| Cost Impact | Higher labor costs | Lower long-term cost |

| Sentiment | Risk of human error (negative) | Reliability and trust (positive) |

At CNCRUSH, we integrate automation into production where feasible, ensuring faster delivery and reduced costs without compromising quality.

7. CNC Machining of Pistons for Automotive Industry

In the automotive sector, pistons must balance weight reduction with strength. Racing engines demand lightweight pistons, while diesel engines require robust steel pistons. Every variant demands CNC machining service tailored to its unique requirements.

CNCRUSH’s experience across diverse industries—including automotive, machine building, and automation—gives us the flexibility to manufacture both standard and custom piston solutions.

8. CNC Milled Parts and CNC Turned Parts for Machine Building

Beyond cars, pistons and piston-like components are also vital in machine building and automation systems. Hydraulic pistons, pneumatic pistons, and actuator components rely heavily on CNC Milled parts and CNC Turned parts.

By providing custom CNC solutions, CNCRUSH helps clients reduce downtime and improve efficiency in large industrial systems. Our positive track record of repeat orders is proof of our reliability.

9. Common Challenges in CNC Machining of Pistons

Challenges include thermal expansion, tool wear, chip evacuation, and tolerance stacking. Negative experiences often occur when manufacturers underestimate the complexity of piston geometry.

At CNCRUSH, we mitigate these risks through:

-

Advanced simulation before cutting.

-

In-process inspection.

-

Expert machinists with years of experience.

This proactive approach reduces rejection rates and guarantees reliable piston machining.

10. Why Choose CNCRUSH for CNC Machining Service?

With 12 years of specialized experience, CNCRUSH offers a complete package:

-

Expertise in CNC Milled parts and CNC Turned parts.

-

Full inspection capability (CMM, hardness testing, micrometers).

-

Flexibility to handle aluminum, steel, and plastics.

-

Global client trust across automotive, machine building, and automation industries.

Clients looking for a reliable CNC machining service provider can visit CNCRUSH.com to discuss projects, request quotes, and benefit from our cost-effective, precision-driven solutions.

FAQ – CNC Machining of Pistons

Q1: Why is CNC Machining critical for pistons?

Because pistons operate under extreme conditions, CNC Machining ensures dimensional accuracy, durability, and performance consistency.

Q2: Can CNCRUSH manufacture both aluminum and steel pistons?

Yes. CNCRUSH has extensive experience machining aluminum, steel, and plastic components, adapting to client requirements.

Q3: How does CNC Milled parts differ from CNC Turned parts in piston manufacturing?

Milled parts handle complex crown geometries and grooves, while turned parts handle cylindrical features like skirts and pin bores.

Q4: What industries rely on piston CNC machining?

Primarily automotive, but also machine building, automation, hydraulics, and aerospace applications.

Q5: Why should international clients choose CNCRUSH?

Because CNCRUSH offers high-precision CNC machining services, backed by 12 years of experience, competitive pricing, and trusted export capabilities.

I really appreciate this post. I have been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thx again!