CNC Machining improves aerospace precision, material handling, and cost-efficiency—discover 10 powerful ways, amps up your manufacturing with CNCRUSH’s expert CNC Machining service. CNC Machining has revolutionized aerospace manufacturing by enabling ultra-precise components production, from turbine blades to structural fasteners. The article consistently highlight:

- Tight tolerance & complex geometry – CNC’s reliability in achieving ±0.005 mm.

- High-performance materials – machining titanium, Inconel, and advanced alloys.

- Quality & certification – aerospace-grade standards (AS9100, NADCAP).

- Cost/time reduction – via CAM, simulation, and automation.

- Surface finish & structural integrity – essential for fatigue resistance.

1. CNC Machining Service Enables Aerospace-Grade Precision and Accuracy

One of the most critical aspects of aerospace manufacturing is the requirement for extreme precision. A single component that is off by even a fraction of a millimeter can result in performance failures or safety issues. CNC Machining service ensures this level of precision through computer-controlled movements and toolpaths, reaching tolerances as tight as ±0.005 mm.

At CNCRUSH, we leverage our 12 years of expertise to consistently deliver CNC frästa delar that meet these exacting standards. Our 5-axis machines allow for complex, multi-dimensional cuts in a single setup, drastically reducing cumulative error and increasing repeatability. Aerospace applications such as jet engine parts, landing gear components, and control surfaces rely on this level of precision to operate safely and efficiently.

Our commitment to precision has won the trust of global aerospace clients. With automated inspection systems and real-time feedback loops, we ensure every component is not just within spec, but optimized for performance.

2. CNC Machining Service Handles High-Performance Alloys in Aerospace

The aerospace industry often uses materials that are extremely difficult to machine due to their hardness, strength, or heat resistance. Titanium, Inconel, stainless steels, and hardened aluminum alloys are all commonplace. These materials are essential for reducing weight while maintaining strength, especially in high-temperature environments such as jet engines.

CNC Machining service shines in this area by using specialized tooling, coolants, and cutting strategies that make it possible to shape these challenging materials without compromising structural integrity. At CNCRUSH, we specialize in machining these alloys into high-quality CNC svarvade delar och CNC frästa delar with minimal tool wear and optimized cutting parameters.

Our engineers routinely assess the machinability of new aerospace alloys and adapt our tooling to maximize efficiency. This not only ensures better parts but also reduces lead times and costs for our customers.

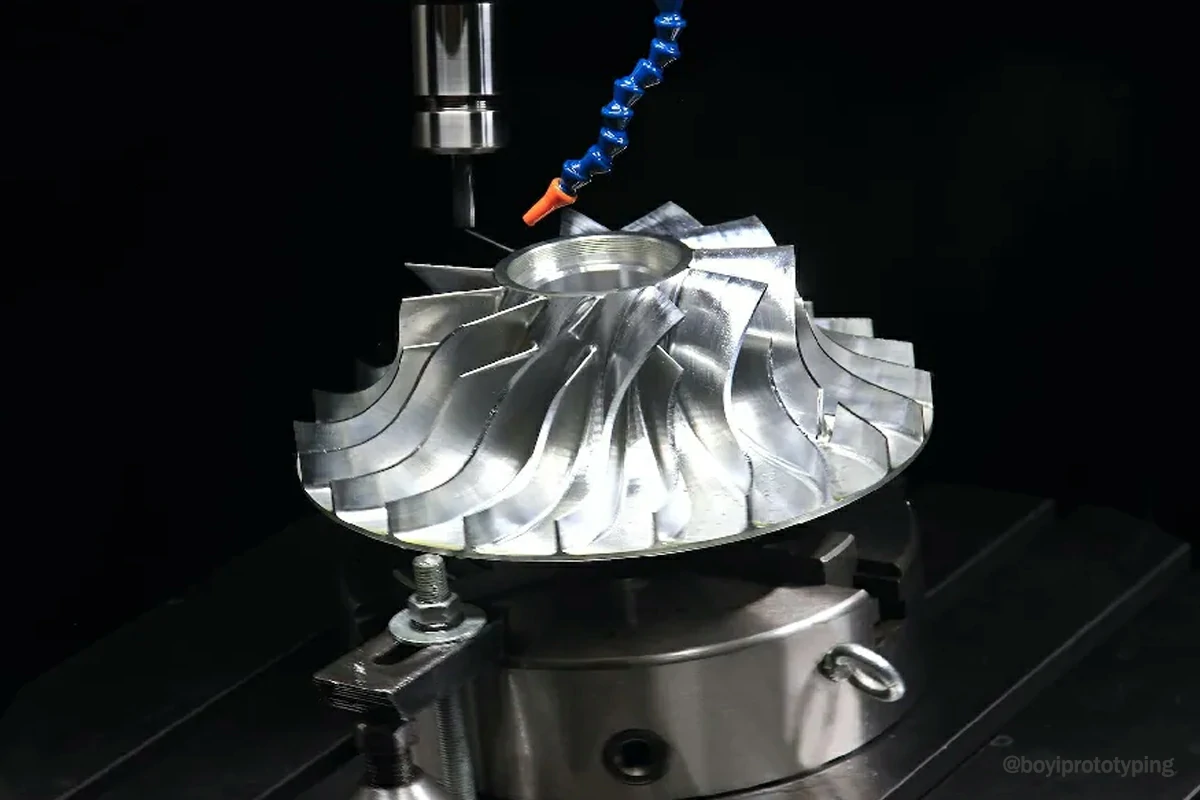

3. CNC Machining Service Supports Complex Geometry & Lightweight Design

Modern aerospace design prioritizes weight reduction without compromising structural performance. To achieve this, components often include intricate internal channels, lattice structures, and thin walls that would be impossible to produce with traditional methods.

CNC Machining service, especially using 5-axis and multi-tasking machines, enables the creation of these geometries with exceptional accuracy. CNCRUSH has extensive experience in producing lightweight and complex CNC frästa delar, including aerodynamic housings, brackets, and heat-exchanger components.

We use simulation and digital twin technology to validate part designs before cutting, ensuring the material is distributed efficiently to maintain strength. This process directly contributes to the performance and fuel efficiency of modern aircraft.

4. CNC Machining Enhances Cost and Time Efficiency in Aerospace Production

Traditional manufacturing methods often require extensive manual labor and multiple setups, which increase the chance of error and elongate lead times. CNC Machining service simplifies this with automation and advanced programming.

At CNCRUSH, our streamlined workflows combine toolpath optimization, fixture design, and real-time monitoring. These capabilities allow us to reduce cycle times and material waste for both CNC svarvade delar och CNC frästa delar.

This is crucial for aerospace clients working on tight schedules and budgets. We can take projects from prototyping to full-scale production without delays, helping our clients maintain competitiveness in a demanding industry.

5. CNC Machining Service Ensures Surface Finish and Structural Integrity

In aerospace, even the smallest surface imperfection can lead to fatigue failure over time. CNC Machining service provides the level of surface quality necessary for these high-stress applications. At CNCRUSH, we achieve Ra values of less than 0.4 μm on demand.

Oavsett om det är turbinblad som kräver perfekta aerodynamiska profiler eller lagerhus som kräver ultrasmarta ytor, så levererar vi. Våra inspektionsystem omfattar CMM:er och ytprovare för att validera varje detalj. Resultatet: CNC frästa delar that perform better and last longer in extreme conditions.

6. CNC Machining Service Ensures Aerospace Certification Compliance

Efterlevnad av internationella standarder är inte valfritt inom flyg- och rymdindustrin - det är obligatoriskt. CNC-bearbetningstjänstleverantörer måste följa AS9100, ISO 9001 och ofta NADCAP-standarder.

CNCRUSH has developed robust quality systems that align with these certifications. Our CNC svarvade delar och CNC frästa delar come with full material traceability, first article inspection reports (FAIR), and process documentation. This level of rigor ensures that every part we ship is audit-ready and compliant with the most stringent aerospace requirements.

7. CNC Machining Service Leverages Advanced CAM and Simulation Tools

The use of Computer-Aided Manufacturing (CAM) and simulation software has become a cornerstone in CNC machining for aerospace. It allows for digital verification of toolpaths, stress analysis, and collision detection before a single chip is made.

At CNCRUSH, we use top-tier CAM platforms and digital twins to simulate machining operations for complex CNC frästa delarDetta möjliggör för oss att identifiera och lösa potentiella problem tidigt, vilket sparar värdefull tid och material. Det är ett proaktivt tillvägagångssätt som minimerar risk och maximerar genomströmning.

8. CNC Machining Service Integrates Automation in Aerospace Manufacturing

Automation plays a growing role in aerospace manufacturing. CNC Machining service providers are increasingly adopting pallet changers, robotic loaders, and lights-out machining systems to increase throughput and reduce costs.

CNCRUSH has integrated automation on several of our CNC production lines, particularly for CNC svarvade delar with repeatable geometries. This not only boosts our capacity but ensures consistent quality and faster turnaround times for our aerospace clients.

9. CNC Machining Service for Multi-Industry Versatility: Aerospace, Automotive, Machine Building and Automotion

One of the hidden strengths of CNC Machining service is its cross-industry applicability. Techniques developed for aerospace—like 5-axis contouring, in-process probing, and zero-point fixturing—can also improve manufacturing outcomes in automotive, machine building and automotion sektorer.

At CNCRUSH, our diverse client base benefits from this knowledge transfer. Aerospace clients get automotive-level cost-efficiency, while automotive clients benefit from aerospace-grade precision. This synergy allows us to apply best practices across industries, enhancing the performance and value of our CNC frästa delar och CNC svarvade delar.

10. CNC Machining Service Fosters Innovation and Future Aerospace Trends

As aerospace moves toward electrification, autonomous flight, and space exploration, the demand for innovative components grows. CNC Machining service remains a crucial enabler of these technologies.

At CNCRUSH, we are exploring hybrid manufacturing methods that combine additive and subtractive processes, allowing us to build smarter CNC svarvade delar with embedded sensors or conformal cooling channels. These innovations are already being adopted by forward-looking aerospace clients.

Our R&D team works closely with clients to prototype and iterate quickly, making us a valuable partner in next-generation aerospace development.

Analytical Tables

Table 1: Comparative Benefits of CNC Machining in Aerospace

| Förmån | CNC Machining Highlights in Aerospace |

|---|---|

| Precision & Accuracy | ±0.005 mm tolerances; ensures aerodynamic stability |

| Materialkapacitet | Titanium, Inconel, aluminum—machinable with accuracy |

| Ytfinish | Ra < 0.4 μm, critical for fatigue life |

| Produktionshastighet | CAM + automation = reduced lead times and costs |

| Certification Readiness | AS9100, NADCAP compliance for traceability |

Table 2: CNCRUSH – Core Offerings & Aerospace Relevance

| Service Offering | Aerospace Focus | Cross‑Industry Impact |

|---|---|---|

| CNC frästa delar | Blades, frames, structural components | Valves, manifolds, tooling for automotive & machinery |

| CNC svarvade delar | Bushings, shafts, fasteners | Automotive shafts, spindles, connectors |

| Materialexpertis | Aluminum, titanium, steel alloys | Plastics, tool steels for broader sectors |

| Quality & Inspection | 100% PI, CMM, RoHS, certification | Applies to medical, auto, and industrial parts |

| Advanced CAM/Automation | Multi-axis machining, lights-out production | Shared tech across machine building, automotion |

FAQ

Q1: What makes CNC Machining service vital for aerospace parts?

A: It enables micron-level precision, complex geometry, and reliable surface finish—meeting aerospace structural and fatigue requirements.

Q2: How does CNCRUSH ensure quality for CNC Turned parts?

A: We implement AS9100-compliant controls, traceable batching, and 100% dimensional inspection using CMMs to guarantee acceptance.

Q3: Can aerospace-grade alloys be machined cost-effectively?

A: Yes—by using optimized toolpaths, tooling, and high-performance hardware, CNCRUSH reduces cycle time and improves efficiency.

Q4: Are your aerospace CNC Milled parts customizable?

A: CNCRUSH supports fully customized geometries, lightweight designs, and even integrated sub-components for advanced platforms.

Call to Action

Looking for a trusted partner offering CNC Machining service for aerospace, automotive, machine building and automotion applications? Explore CNCRUSH: with over 12 years of experience delivering CNC frästa delar och CNC svarvade delar, we combine skilled craftsmanship, aerospace certification, and efficiency. Visit CNCRUSH’s professional factory in China and request a quote to see how precision machining can elevate your aerospace manufacturing success.