In today’s rapidly evolving manufacturing landscape, CNC milling has become the gold standard for producing high-precision parts, especially in industries like automotive, machine building, and automation. Among the materials that have gained substantial popularity in CNC machining, aluminum stands out as a versatile, lightweight, and cost-effective choice. Aluminum is an ideal material for a wide variety of applications due to its excellent strength-to-weight ratio, corrosion resistance, and ease of machining.

This article will take a deep dive into the 7 most powerful benefits of CNC milling for aluminum parts, showcasing why CNC machining services are an essential asset for businesses seeking top-tier CNC milled parts and CNC turned parts for automotive, machine building, and automation industries. Additionally, we’ll explore how CNCRUSH, a China CNC factory with over 12 years of experience, can help you with high-quality CNC machining solutions.

Whether you’re new to CNC machining or are looking to optimize your manufacturing processes, this comprehensive guide will provide you with the insights you need to make informed decisions.

1. Exceptional Precision for Aluminum Parts

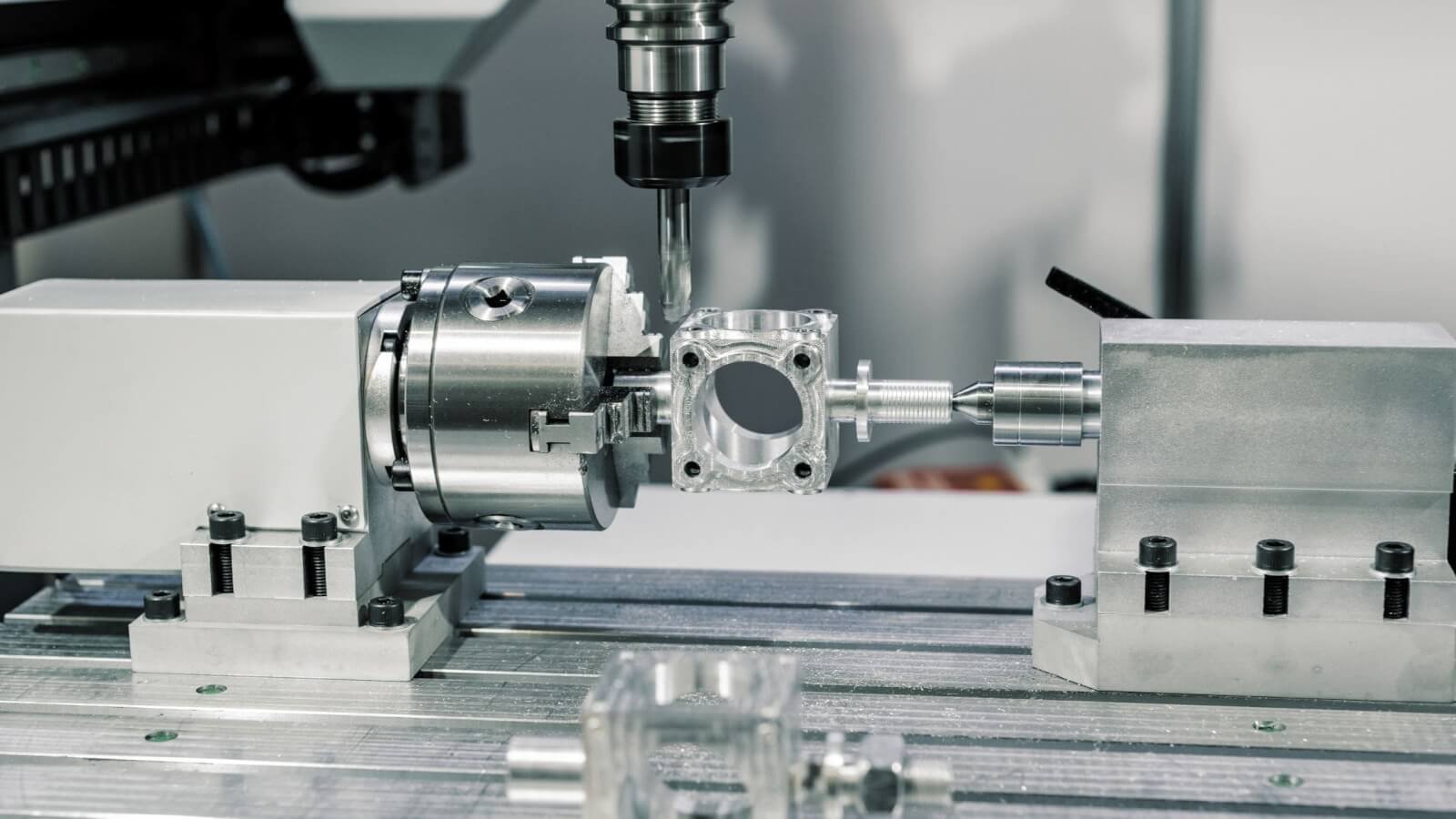

When it comes to CNC machining for aluminum parts, precision is critical. CNC milling enables manufacturers to achieve high levels of accuracy, which is crucial for applications that demand tight tolerances, like in the automotive and machine building sectors. Using advanced CNC machinery, manufacturers can produce complex aluminum parts with micrometer-level precision that manual machining methods simply cannot match.

At CNCRUSH, we specialize in providing custom CNC solutions for CNC milled parts and CNC turned parts, ensuring that all parts are produced to meet or exceed client specifications. Our precision CNC machining capabilities guarantee flawless results that will keep your project on track, whether it’s for an automotive component or an industrial machine.

2. Excellent Material Versatility for a Variety of Applications

Aluminum’s flexibility makes it an ideal material for a wide range of industries. From lightweight components for automotive applications to intricate parts for machine building, aluminum can be easily shaped and processed using CNC milling machines. It’s widely used in everything from aircraft parts to consumer electronics and robotics due to its unique combination of strength and lightweight properties.

Whether you’re looking for CNC machining services for aluminum brackets, gears, or even specialized components for automation systems, CNCRUSH offers CNC machining in China that can cater to all your production needs, ensuring your aluminum parts meet your specific application requirements.

3. Reduced Production Time and Enhanced Efficiency

One of the standout benefits of CNC milling for aluminum parts is the reduction in production time compared to traditional machining methods. CNC machines can operate 24/7, reducing lead times and increasing overall efficiency. Whether you’re producing CNC milled parts or CNC turned parts, CNC machining services streamline the manufacturing process, allowing for faster turnaround times without sacrificing quality.

Our facility at CNCRUSH utilizes state-of-the-art CNC milling and turning machines that are capable of operating at high speeds, ensuring that your aluminum parts are delivered quickly and efficiently, no matter the volume.

4. Increased Cost-Efficiency for High-Volume Production

Although CNC milling requires an initial investment in equipment and setup, the long-term cost benefits far outweigh the initial expense, especially for high-volume production. Once the CNC machine is set up, it can produce large quantities of CNC milled parts with minimal supervision and consistent quality. This makes it an economical choice for large-scale production runs.

If you’re looking for an affordable CNC machining service that doesn’t compromise on quality, CNCRUSH provides cost-effective solutions without cutting corners. Our expertise in CNC milling and turning ensures that your aluminum parts are produced at the best possible price while maintaining exceptional precision.

5. Consistent Quality and Minimal Defects

One of the greatest advantages of CNC milling for aluminum parts is the consistency of the final product. Unlike manual machining, which can introduce human error, CNC machining operates under computer-controlled instructions that eliminate variability. This consistency is especially crucial when producing parts for industries like automotive or machine building, where defects can lead to costly delays and safety issues.

At CNCRUSH, our CNC machining experts ensure that every part is machined to the same high standard, and we back up our production with CMM (Coordinate Measuring Machine) reports and FAIR (First Article Inspection Reports), which can further guarantee the quality of your CNC milled parts.

6. Superior Surface Finish and Aesthetic Appeal

CNC milling not only ensures high precision but also allows for superior surface finishes that meet the highest standards for aesthetic appeal. This is particularly important in industries such as automotive, where components need to maintain both function and appearance. Aluminum’s natural corrosion resistance, coupled with the smooth surface finish achieved by CNC milling, makes it an ideal choice for exposed parts that need to withstand harsh environments.

CNCRUSH offers a variety of post-processing options, such as anodizing, to enhance the surface finish of your aluminum parts. Whether you need a CNC milled part with a glossy finish for aesthetic reasons or a durable finish for functional use, we have you covered.

7. Environmentally Friendly Option

Aluminum is 100% recyclable, which makes it an environmentally friendly choice for manufacturing. CNC machining for aluminum parts reduces waste and energy consumption compared to traditional machining methods. Since aluminum is lightweight and requires less energy to process, it also has a lower carbon footprint, making it a great material choice for sustainable manufacturing.

At CNCRUSH, we are committed to sustainable practices and strive to minimize waste in our CNC machining services. Our focus on efficiency and precision helps reduce material waste, further enhancing the eco-friendly nature of our CNC machining for metal parts.

Table 1: Key Advantages of CNC Milling for Aluminum Parts

| Benefit | Explanation |

|---|---|

| Precision | CNC milling ensures high levels of accuracy, perfect for tight tolerances. |

| Material Versatility | Aluminum’s lightweight and strong properties make it ideal for various applications. |

| Cost-Efficiency | CNC milling reduces production costs in high-volume runs due to reduced labor and material waste. |

| Surface Finish | CNC machining can achieve superior surface finishes for both aesthetic and functional purposes. |

| Sustainability | Aluminum’s recyclability makes it an eco-friendly choice for manufacturing. |

FAQ Section:

Q1: Why should I choose CNC milling over other machining methods for aluminum parts? CNC milling offers greater precision, faster production times, and superior consistency, making it an excellent choice for high-quality aluminum parts in industries like automotive and machine building.

Q2: Can CNCRUSH handle both small and large production runs for aluminum parts? Yes, at CNCRUSH, we are equipped to handle both small and large production runs, providing CNC machining services that meet the highest standards for both quantity and quality.

Q3: How can I ensure my aluminum parts meet the exact specifications I need? By working with CNCRUSH, you can rest assured that we will deliver precision and consistency through our CNC machining for aluminum parts, including comprehensive inspection reports such as CMM and FAIR to ensure accuracy.

Conclusion

The benefits of CNC milling for aluminum parts are clear—high precision, reduced production time, cost-efficiency, and exceptional quality. Whether you are in the automotive, machine building, or automation industry, CNC machining services can provide the reliability and flexibility you need to meet your manufacturing goals.

If you’re looking for precision CNC machining services, CNCRUSH offers high-quality CNC milled parts and CNC turned parts that are perfect for your next project. With over 12 years of experience and a state-of-the-art facility in China CNC factory, we’re equipped to provide you with the best CNC machining solutions at affordable prices.

Visit CNCRUSH today and get started on your next project with our expert CNC machining services!