As the manufacturing industry continues to evolve, CNC machining is at the forefront of innovation, driven by advances in automation and artificial intelligence (AI). These technologies promise to transform CNC machining, making processes more efficient, precise, and cost-effective. In this article, we’ll explore the future of CNC machining by examining how automation and AI are reshaping the industry, while also discussing the critical role these technologies will play in enhancing the CNC machining services provided by industry leaders like CNCRUSH.

CNCRUSH, a leading CNC machining service provider in China with over 12 years of experience, specializes in CNC Milled parts and CNC Turned parts for industries such as automotive, machine building, and automation. As the industry integrates more automation and AI, CNCRUSH stands ready to leverage these technologies to enhance production efficiency, deliver high-quality parts, and meet the growing demands of the modern manufacturing landscape.

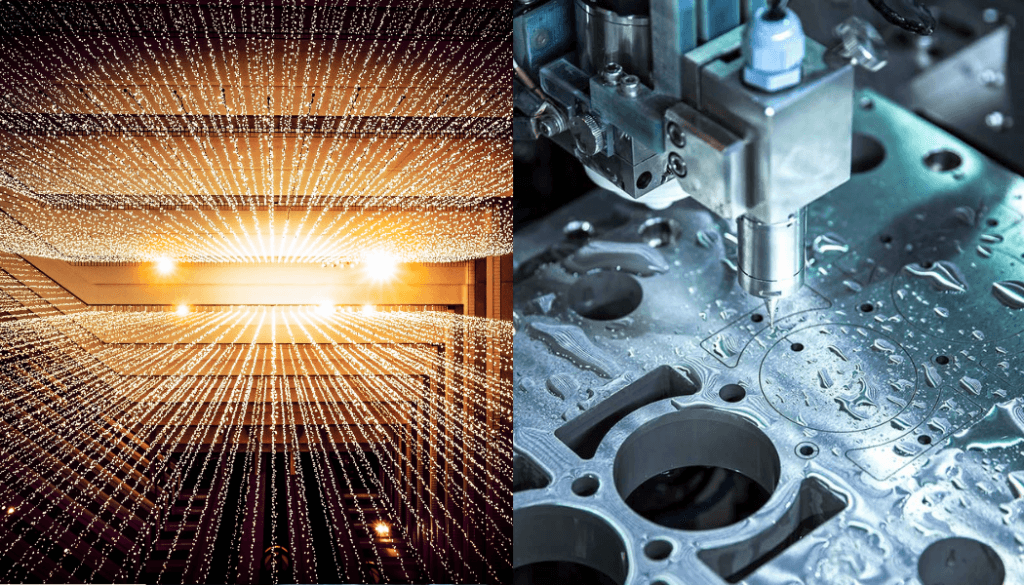

1. AI and Automation in CNC Machining

CNC machining has already benefited from advancements in automation, such as automatic tool changers, pallet systems, and robotic part handling. These technologies have significantly reduced the need for human intervention, allowing for faster production times and higher precision. As we move into the future, AI will play an even greater role by optimizing the CNC machining service process.

AI can analyze large datasets, enabling CNC machines to make real-time decisions, such as adjusting feed rates and tool paths for maximum efficiency. This not only reduces cycle times but also enhances the accuracy of CNC Milled parts and CNC Turned parts. The integration of AI with CNC machines is already helping companies like CNCRUSH meet tight deadlines and maintain high-quality standards in sectors like automotive and machine building.

2. The Benefits of AI-Driven CNC Machining

The implementation of AI in CNC machining services provides several key advantages:

- Predictive Maintenance: AI systems can monitor CNC machines in real-time, identifying potential issues before they cause breakdowns. This proactive approach minimizes downtime and extends the lifespan of critical machinery, which is especially important for high-precision operations like those at CNCRUSH.

- Improved Precision: AI enables CNC machines to analyze vast amounts of data during the machining process, making real-time adjustments to ensure optimal cutting conditions. This results in superior part quality, reducing errors and material wastage.

- Increased Efficiency: By analyzing operational data, AI can optimize machining processes, reducing cycle times and energy consumption. For example, AI can automatically adjust tool paths to minimize tool wear, leading to cost savings and enhanced production capabilities.

3. Automation’s Role in Increasing Productivity

Automation is already making a significant impact on the productivity of CNC machining services. Robots and automated systems can work around the clock without fatigue, enabling continuous production. This is particularly beneficial for companies like CNCRUSH, which cater to industries with high-volume production demands, such as automotive and automation.

Robots can be used to handle repetitive tasks, such as loading and unloading materials or changing tools, freeing up skilled workers to focus on more complex operations. This also reduces the risk of human error and increases overall productivity.

| Technology | Impact on CNC Machining |

|---|---|

| Robotics | Increased efficiency and reduced human error in material handling and tool changes. |

| Automated Tool Changers | Faster transitions between tools, reducing downtime and improving cycle times. |

| Real-Time Monitoring | Enhanced process control through live data analysis, ensuring continuous machine optimization. |

4. The Role of AI in Optimizing CNC Processes

AI’s ability to analyze and interpret data makes it a perfect fit for optimizing CNC machining processes. AI-driven software can analyze operational parameters such as cutting speed, tool wear, and spindle load to recommend adjustments that will enhance productivity. For instance, it can automatically adjust feed rates to optimize material removal rates without causing tool overload or excessive heat buildup.

By integrating AI with existing CAM (Computer-Aided Manufacturing) systems, companies like CNCRUSH can further enhance their CNC machining services, ensuring faster production cycles and lower operational costs.

5. CNC Machining and Industry 4.0

The future of CNC machining lies in the seamless integration of Industry 4.0 technologies, such as the Internet of Things (IoT), cloud computing, and big data analytics. These technologies enable the creation of “smart factories,” where machines are interconnected, sharing real-time data to optimize operations.

For instance, CNC machines can communicate with each other to coordinate tasks, ensuring that production schedules are met efficiently. At CNCRUSH, the adoption of Industry 4.0 technologies can enhance CNC machining services by providing greater visibility into production processes, improving quality control, and enabling more responsive manufacturing systems.

6. Challenges of Integrating AI in CNC Machining

While the benefits of AI and automation are clear, their integration into CNC machining services does present challenges. One of the main obstacles is the significant investment required to implement these technologies. Smaller CNC machining operations may struggle to justify the cost of upgrading their machinery and software systems to accommodate AI-driven processes.

However, for companies like CNCRUSH, which specialize in CNC Milled parts and CNC Turned parts for high-demand sectors, the long-term benefits outweigh the initial costs. By adopting AI-driven solutions, CNCRUSH can reduce operational costs, improve part quality, and remain competitive in the global market.

7. AI in Quality Control and Inspection

AI is also transforming quality control in CNC machining services. Traditionally, quality inspection has been a manual process, prone to errors and time-consuming. With AI-powered machine vision systems, CNC machines can perform real-time quality inspections, identifying defects as parts are being produced. This reduces the need for post-production inspections and ensures that only high-quality parts leave the factory floor.

By incorporating AI-driven inspection systems, CNCRUSH can further enhance the quality of their CNC Milled parts and CNC Turned parts, ensuring they meet the stringent requirements of industries like automotive and machine building.

| Inspection Technology | Benefits in CNC Machining |

|---|---|

| AI-Powered Vision Systems | Real-time defect detection, reducing post-production inspection times. |

| Automated Measurement Tools | Higher accuracy in measuring part tolerances, ensuring consistent quality. |

8. Predictive Maintenance and Cost Savings

Predictive maintenance is one of the most promising applications of AI in CNC machining. AI can analyze machine data to predict when a part or tool will fail, allowing for maintenance to be scheduled before a breakdown occurs. This reduces unplanned downtime and minimizes repair costs.

For a company like CNCRUSH, implementing predictive maintenance systems can lead to significant cost savings, as machines can be kept running at optimal efficiency without unexpected interruptions. Additionally, predictive maintenance extends the lifespan of machines and tools, reducing the need for frequent replacements.

9. AI in Custom CNC Solutions

Another exciting application of AI in CNC machining is its ability to aid in custom CNC solutions. AI can analyze customer specifications and automatically generate optimized tool paths, ensuring that custom parts are produced with the highest precision and efficiency. This is particularly valuable for industries like automotive, where custom CNC Milled parts and CNC Turned parts are often required to meet specific design and performance criteria.

CNCRUSH can use AI-driven systems to offer faster turnaround times on custom parts, while maintaining the highest quality standards. This ability to provide custom CNC solutions further strengthens CNCRUSH’s position as a leading provider of CNC machining services.

10. The Future of CNC Machining Services at CNCRUSH

As AI and automation continue to shape the future of CNC machining, companies like CNCRUSH are well-positioned to take advantage of these technologies. By integrating AI-driven tools and automated systems, CNCRUSH can enhance its CNC machining services, offering customers faster production times, higher precision, and greater flexibility.

With over 12 years of experience, CNCRUSH remains committed to staying at the forefront of CNC technology, providing innovative solutions to industries like automotive, machine building, and automation. As AI and automation evolve, CNCRUSH will continue to adapt, delivering high-quality CNC Milled parts and CNC Turned parts to clients around the world.

FAQ: CNC Machining and AI Integration

Q1: How does AI improve the efficiency of CNC machining?

AI optimizes CNC machining by analyzing real-time data to adjust tool paths, feed rates, and other parameters, reducing cycle times and improving precision.

Q2: Will AI replace human operators in CNC machining?

No, AI will complement human operators by automating repetitive tasks and enhancing machine performance. Skilled operators will still be needed to oversee processes and handle complex operations.

Q3: How does automation benefit CNC machining services?

Automation increases productivity by enabling continuous, 24/7 operation, reducing human error, and improving part quality, making it ideal for high-demand sectors like automotive and machine building.

The future of CNC machining is bright, with AI and automation playing critical roles in enhancing production efficiency and quality. CNCRUSH is poised to lead this transformation, delivering world-class **CNC machining