5 Eksenli CNC İşleme is revolutionizing aerospace manufacturing by enabling the production of highly complex components with exceptional precision and efficiency. In this article, we summarize key insights from industry-leading sources and combine them with the expertise of CNCRUSH—a professional CNC işleme hizmeti provider in China with 12+ years of experience in delivering premium CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar. We cover the advantages, technical challenges, emerging trends, and best practices associated with 5-axis machining, especially in the aerospace sector, while also addressing related applications in automotive, machine building, and automotion industries.

Drawing upon insights from LinkedIn articles, aerospace manufacturing blogs, and industry experts, we present 10 in-depth discussions. Each section is designed to help engineers, production managers, and decision-makers understand how 5-axis machining drives innovation and quality in aerospace components. Let’s dive into each topic for a comprehensive overview.

1. 5-Axis CNC Machining: What It Is and Why It Matters

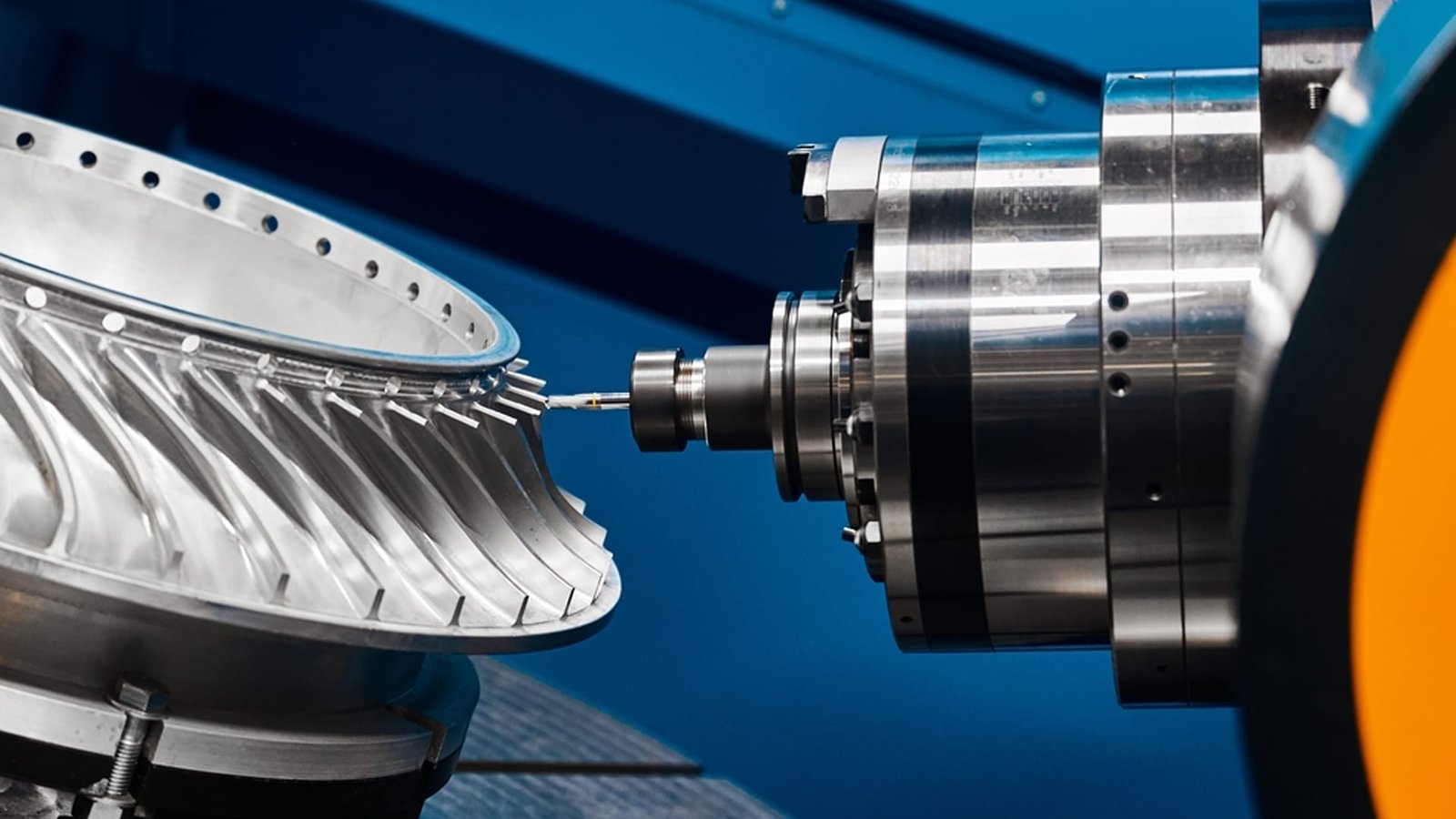

5 Eksenli CNC İşleme represents an advanced manufacturing process where a cutting tool moves simultaneously along five different axes. This multidimensional movement enables the production of highly complex geometries that would be impossible or impractical with traditional 3-axis machining.

Temel Avantajlar:

- Enhanced Precision: The ability to tilt and rotate the cutting tool minimizes the need for multiple setups and ensures tighter tolerances.

- Karmaşık Geometriler: Complex curves, deep pockets, and intricate contours can be achieved in one setup.

- Azaltılmış Kurulum Süresi: Fewer repositionings reduce errors and speed up production.

- Geliştirilmiş Yüzey Kaplaması: Consistent tool engagement results in smoother surfaces, which is crucial for aerospace safety and performance.

This advanced process is particularly significant for aerospace applications, where even minor inaccuracies can compromise component performance and safety. When integrated into high-end production lines, 5 Eksenli CNC İşleme drastically enhances both the quality and the speed of production.

2. The Growing Demand for 5-Axis CNC Machining in Aerospace

The aerospace industry increasingly relies on 5 Eksenli CNC İşleme to meet the rigorous demands of modern aircraft and spacecraft components. High-performance parts such as turbine blades, engine housings, and structural frames require not only precision but also the ability to withstand extreme operating conditions.

Industry Drivers:

- Stricter Quality Standards: Aerospace parts must meet stringent regulatory and safety standards.

- Karmaşık bileşen tasarımları: Modern aircraft designs require parts with intricate geometries that only 5-axis machines can produce efficiently.

- Maliyet Verimliliği: Although initial investments are higher, reduced setup times and lower scrap rates translate into long-term savings.

- Innovation in Materials: High-performance materials like titanium, Inconel, and advanced aluminum alloys are best machined with multi-axis capabilities.

By using advanced CNC işleme hizmeti providers like CNCRUSH, aerospace manufacturers can rely on experienced partners to deliver high-quality CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar that consistently meet exacting specifications.

3. Key Technologies in 5-Axis CNC Machining Service for Aerospace

Modern 5 Eksenli CNC İşleme integrates several cutting-edge technologies to enhance accuracy and performance. Providers such as CNCRUSH use a combination of hardware and software innovations to ensure precision, even for the most demanding aerospace components.

Essential Technologies:

- Yüksek hızlı işleme (HSM): Enables faster cutting while maintaining dimensional accuracy.

- Multi-Axis Toolpath Optimization: Software algorithms that design optimal tool paths, reducing tool wear and cycle times.

- Adaptive Machining and Feedback Systems: Real-time sensors adjust cutting parameters based on force, temperature, and vibration data.

- CAD/CAM Integration: Seamless integration of design and manufacturing data ensures that every part is produced exactly as designed.

These technologies not only improve production quality but also reduce overall manufacturing costs by minimizing downtime and material waste. As a leader in the field, CNCRUSH leverages these advanced technologies to offer comprehensive CNC işleme hizmeti solutions that include both CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar.

4. Materials Used in Aerospace 5-Axis CNC Machining and Their Impact on Performance

Aerospace components demand materials that offer high strength-to-weight ratios, durability, and resistance to extreme conditions. 5 Eksenli CNC İşleme is well-suited for processing these advanced materials, ensuring optimal performance and reliability.

Common Materials:

- Titanyum: Known for its excellent strength and lightweight properties, titanium is widely used in engine parts and airframes.

- Aluminum Alloys: Favored for their machinability and low weight, these alloys are common in fuselage structures and brackets.

- İnkonel: A nickel-chromium superalloy used for components exposed to high temperatures and corrosive environments.

- Paslanmaz çelik: Utilized for its strength and durability, especially in critical fastening and structural components.

The right material choice combined with precise 5-axis machining can dramatically improve the final part’s performance. CNCRUSH’s expertise in machining various materials ensures that every component—be it a CNC Frezelenmiş parça veya bir CNC Tornalanmış parça—meets the highest quality standards required by the aerospace industry.

5. How CNCRUSH Delivers High-Quality 5-Axis CNC Machining Service for CNC Milled parts

At CNCRUSH, our commitment to excellence in CNC işleme hizmeti is evident in every project we undertake. With over 12 years of experience, our state-of-the-art facility in China is dedicated to providing precision CNC machining services tailored to the aerospace sector.

Yaklaşımımız:

- Gelişmiş Ekipman: Our 5-axis CNC machines are among the best in the industry, capable of delivering exceptional accuracy.

- Skilled Workforce: Our engineers and machinists are experts in programming and operating multi-axis machines.

- Kalite Kontrolü: Rigorous inspection protocols (including CMM and automated inspection systems) ensure every CNC Frezelenmiş parça meets exacting standards.

- Customer-Centric Solutions: We collaborate closely with clients in aerospace, automotive, machine building, and automotion to provide custom CNC solutions.

By choosing CNCRUSH, customers benefit from tailored, high-quality machining services that optimize production cycles and ensure cost efficiency. Our integrated approach guarantees that each component is produced with the highest precision possible.

6. Cost Analysis: 5-Axis CNC Machining vs. Traditional 3-Axis CNC Machining

Although 5 Eksenli CNC İşleme requires a higher initial investment, its long-term benefits often outweigh the costs when compared to traditional 3-axis machining. The reduced need for multiple setups, lower scrap rates, and increased part accuracy lead to overall cost savings.

Comparative Analysis Table:

| Faktör | Traditional 3-Axis CNC | 5 Eksenli CNC İşleme |

|---|---|---|

| Kurulum Süresi | Longer, multiple setups | Significantly reduced |

| Malzeme Atığı | Daha yüksek | Lower due to precision cuts |

| Dimensional Accuracy | Ilıman | Superior precision |

| Yüzey İşlemi | Requires post-processing | Excellent right out of machine |

| Döngü Süresi | Yavaş | Daha hızlı üretim döngüleri |

The efficiency gains achieved through 5-axis machining often translate into higher production volumes and reduced labor costs. This is particularly important for industries such as aerospace and automotive, where high-quality CNC Tornalanmış parçalar Ve CNC Frezelenmiş parçalar çok önemlidir.

7. Overcoming Challenges in 5-Axis CNC Machining for Complex Aerospace Components

Even with its many benefits, 5 Eksenli CNC İşleme presents certain challenges. Advanced programming requirements, potential tool interference, and higher machine costs can create hurdles that must be overcome to fully leverage this technology.

Common Challenges and Solutions:

- Programming Complexity: Advanced CAM software and experienced programmers are required to design optimal tool paths. Continuous training and software upgrades are critical.

- Tool Interference: Careful planning and simulation help avoid collisions and ensure proper tool clearance.

- High Initial Investment: Although the upfront cost is high, the improved efficiency and reduced scrap rates provide a favorable return on investment.

- Maintenance Demands: Regular maintenance schedules and the use of predictive maintenance technology help in minimizing downtime.

By addressing these challenges head-on, CNCRUSH ensures that each project is executed with precision and minimal risk. Our robust quality control systems and proactive maintenance strategies keep our 5-axis machines operating at peak efficiency, delivering flawless parts every time.

8. Future Trends in 5-Axis CNC Machining for Aerospace and Beyond

geleceği 5 Eksenli CNC İşleme is evolving rapidly, driven by innovations in automation, artificial intelligence (AI), and sustainable manufacturing practices. These trends are set to further enhance precision, efficiency, and cost-effectiveness in aerospace production.

Ortaya çıkan trendler:

- AI odaklı optimizasyon: Machine learning algorithms will further refine tool paths and cutting parameters.

- Dijital İkiz Teknolojisi: Creating virtual replicas of machining processes allows for simulation and real-time optimization.

- Hibrit Üretim: The integration of 3D printing with 5-axis machining is enabling new design possibilities.

- Sustainability: Advancements in eco-friendly machining techniques are reducing energy consumption and material waste.

CNCRUSH is at the forefront of these innovations, continuously investing in new technologies to offer state-of-the-art CNC işleme hizmeti solutions that not only meet today’s demands but also prepare for tomorrow’s challenges.

9. How to Choose the Best 5-Axis CNC Machining Partner for CNC Turned parts and CNC Milled parts

Selecting the right partner for 5 Eksenli CNC İşleme is critical for achieving production goals. For industries like aerospace, automotive, and machine building, the reliability, quality, and expertise of your machining service provider can significantly impact your product’s performance.

Key Selection Criteria:

- Certifications & Quality Standards: Look for providers with ISO, AS9100, or equivalent certifications.

- Industry Experience: Ensure the provider has a proven track record in aerospace and other high-precision sectors.

- Technology & Equipment: Evaluate the machinery, software, and maintenance protocols in place.

- Customer Support: Strong communication and a customer-centric approach are essential for resolving issues quickly.

- Case Studies & Testimonials: Real-world examples and positive feedback from past clients can provide valuable insight.

At CNCRUSH, our 12+ years of experience, state-of-the-art 5-axis CNC machines, and commitment to continuous improvement make us an ideal partner for companies seeking top-quality CNC Tornalanmış parçalar Ve CNC Frezelenmiş parçalar.

10. Getting Started with CNCRUSH’s 5-Axis CNC Machining Services for Aerospace and Beyond

For businesses looking to enhance their production with advanced 5 Eksenli CNC İşleme, partnering with a trusted provider is the key to success. CNCRUSH is your go-to CNC işleme hizmeti provider in China, with a proven track record of delivering high-precision parts tailored for aerospace, automotive, machine building, and automotion industries.

How We Can Help:

- Özel CNC Çözümleri: We provide bespoke machining services to meet your unique requirements.

- Comprehensive Support: From initial design to final quality inspection, our team is with you every step of the way.

- Advanced Capabilities: Our facility is equipped to produce both CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar with superior precision.

- Küresel Erişim: Trusted by clients worldwide, we offer reliable and cost-effective solutions for high-demand applications.

Ziyaret etmek CNCRUSH today to learn more about our services and to request a free consultation. Let us help you achieve excellence in every component with our advanced 5-axis machining technology.

Comparative Analysis: 5-Axis CNC Machining vs. Traditional Machining Methods

To provide clarity on the benefits of 5-axis machining over conventional methods, the following tables offer a side-by-side comparison of key performance factors and overall advantages.

Table 1: Key Performance Comparison

| Parametre | Traditional 3-Axis CNC | 5 Eksenli CNC İşleme |

|---|---|---|

| Kurulum Süresi | Birden fazla kurulum gerekli | Single setup, reduced errors |

| Kesinlik | Moderate tolerances | Superior precision with multi-axis control |

| Yüzey İşlemi | May require additional finishing | Excellent surface quality directly from machine |

| Takım Aşınması | Higher due to repetitive setups | Optimized tool paths reduce wear |

| Döngü Süresi | Daha uzun üretim döngüleri | Faster, more efficient production |

Table 2: Benefits of Partnering with CNCRUSH for 5-Axis CNC Machining Services

| Bakış açısı | General Providers | CNCRUSH Advantages |

|---|---|---|

| Deneyim | Limited to standard machining | 12+ years of specialized expertise |

| Özelleştirme | Often standardized processes | Tailored CNC Milled parts and CNC Turned parts solutions |

| Teknoloji | Basic equipment | State-of-the-art 5-axis CNC machines |

| Kalite Güvencesi | Basic QC protocols | Rigorous ISO-certified quality control |

| Industry Compliance | Değişken | Adherence to aerospace, automotive, and machine building standards |

SSS: 5 Eksenli CNC İşleme

Q1: What makes 5-Axis CNC Machining essential for aerospace components?

A1: 5 Eksenli CNC İşleme allows for the production of highly complex geometries with superior precision, reduced setups, and enhanced surface finishes. These attributes are crucial for aerospace components that must meet rigorous safety and performance standards.

Q2: CNCRUSH, yüksek kaliteli CNC Freze parçaları ve CNC Tornalama parçalarını nasıl sağlar?

A2: CNCRUSH uses state-of-the-art 5-axis machines, advanced CAM software, and rigorous quality control processes. Our experienced engineers tailor each project to meet the precise specifications required by aerospace, automotive, machine building, and automotion industries.

Q3: Can 5-axis machining reduce production costs in the long term?

A3: Yes, despite a higher initial investment, 5-axis machining reduces setup time, minimizes material waste, and improves tool life, resulting in significant cost savings over time.

Q4: What industries can benefit from 5-Axis CNC Machining?

A4: While aerospace is a primary beneficiary, industries such as automotive, machine building, and automotion also greatly benefit from the precision and efficiency of 5-axis machining.

Q5: How can I get started with CNCRUSH’s 5-Axis CNC Machining services?

A5: Simply visit CNCRUSH Hizmetlerimiz hakkında daha fazla bilgi edinmek, danışmanlık talep etmek veya fiyat teklifi almak için ekibimiz, benzersiz üretim ihtiyaçlarınızı karşılamak üzere tasarlanmış özel çözümlerimiz konusunda size rehberlik edecektir.

Sonuç: Gelişmiş 5 Eksenli CNC İşleme ile Havacılık ve Uzay Üretiminde Dönüşüm

Sonuç olarak, 5 Eksenli CNC İşleme havacılık ve uzay üretiminde dönüştürücü bir güç olarak eşsiz hassasiyet, verimlilik ve maliyet etkinliği sağlar. Üreticiler, en son teknolojileri entegre ederek, karmaşık geometrileri optimize ederek ve gelişmiş otomasyondan yararlanarak geleneksel sınırlamaların üstesinden gelebilir ve üstün havacılık ve uzay bileşenleri üretebilir.

Her alanda mükemmellik talep eden işletmeler için CNC Frezelenmiş parça Ve CNC Tornalanmış parça, güvenilir bir şirketle ortaklık CNC işleme hizmeti CNCRUSH, 12 yılı aşkın deneyimiyle havacılık, otomotiv, makine imalatı ve otomotiv endüstrilerinin zorlu taleplerini, inovasyon ve kaliteyi destekleyen özel CNC çözümleriyle karşılamak için benzersiz bir konuma sahiptir.

CNCRUSH'ın gelişmiş 5 eksenli işleme yetenekleriyle üretimin geleceğini kucaklayın. Uzmanlığımızın ve en son teknolojimizin üretim sürecinizi nasıl dönüştürebileceğini ve performansta yeni standartlar belirleyen hassas, yüksek kaliteli bileşenler sunabileceğini keşfedin. Bize bugün şu adresten ulaşın CNCRUSH ve gerçek üretim mükemmelliğinin yaratabileceği farkı deneyimleyin.