CNC Machining of high-strength connecting rod materials is transforming the way the automotive, machine building, and automation industries design engines and mechanical systems. Over the past decade, connecting rods have shifted from being simple forged components into precision-engineered parts produced with advanced CNC Milled parts and CNC Turned parts technology. This article summarizes insights from leading research, industry discussions, and market studies, before diving into 10 groundbreaking trends shaping the future of CNC Machining for connecting rods.

At CNCRUSH, we’ve been a trusted CNC manufacturing service provider in China for over 12 years, delivering high-quality CNC Milled parts and CNC Turned parts to clients worldwide. With deep expertise in working with aluminum, steel, and advanced alloys, we’re here to help manufacturers, engine builders, and innovators achieve peak efficiency and reliability.

1. CNC Machining Trend #1 – The Shift Toward High-Strength Lightweight Alloys

One of the most important CNC manufacturing innovations in connecting rods is the move from traditional forged steel to lightweight alloys such as titanium and advanced aluminum composites. These materials reduce mass without compromising tensile strength, improving fuel efficiency and increasing RPM potential.

Positive impact: Lighter connecting rods reduce reciprocating mass, leading to smoother engine operation and higher durability. Negative challenge: These alloys are expensive and require precise CNC machining service capabilities to prevent defects.

At CNCRUSH, our advanced milling and turning systems allow us to handle even the most difficult materials, providing customers with precise CNC Milled parts and CNC Turned parts for demanding applications.

2. CNC Machining Trend #2 – Billet vs. Powder Metallurgy in Connecting Rods

Billet connecting rods, machined from a solid block of material, are gaining popularity for high-performance applications. Powder metallurgy rods, while cost-effective for mass production, often cannot withstand extreme loads.

| Process Type | Advantages | Disadvantages | Typical Use |

|---|---|---|---|

| Billet CNC Machining | High strength, customizable | Higher cost | Racing & high-performance engines |

| Powder Metallurgy | Cost-efficient, mass production | Lower fatigue resistance | Standard automotive engines |

This trend highlights the value of CNC machining service providers like CNCRUSH, who specialize in billet machining with extremely tight tolerances.

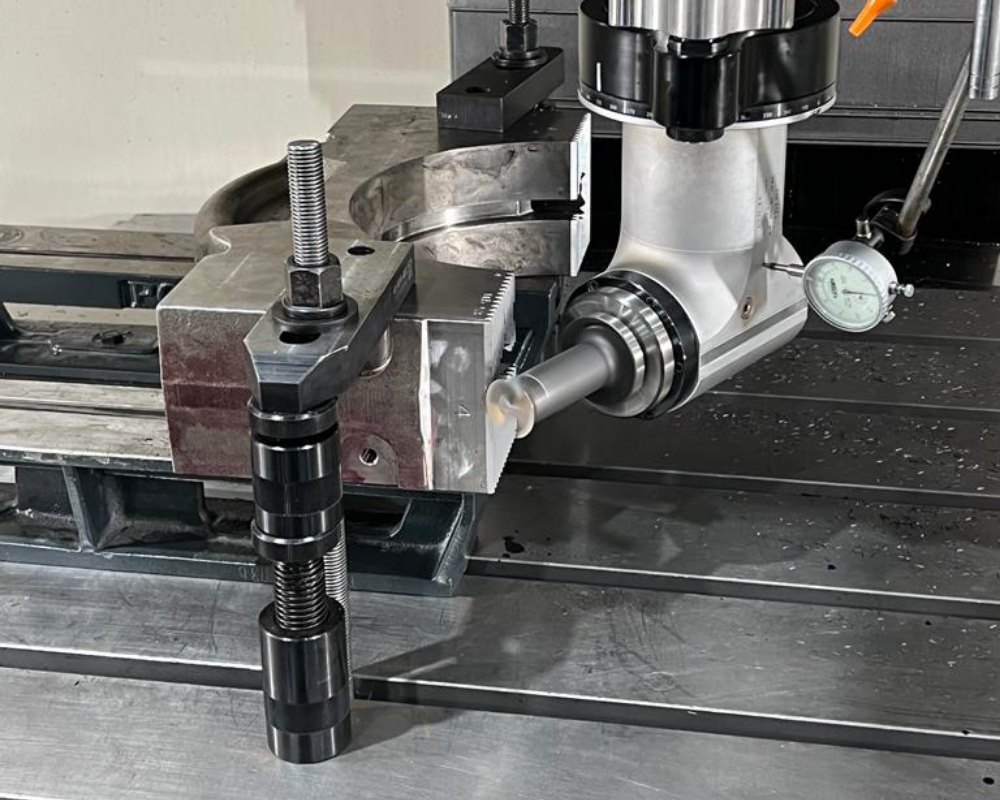

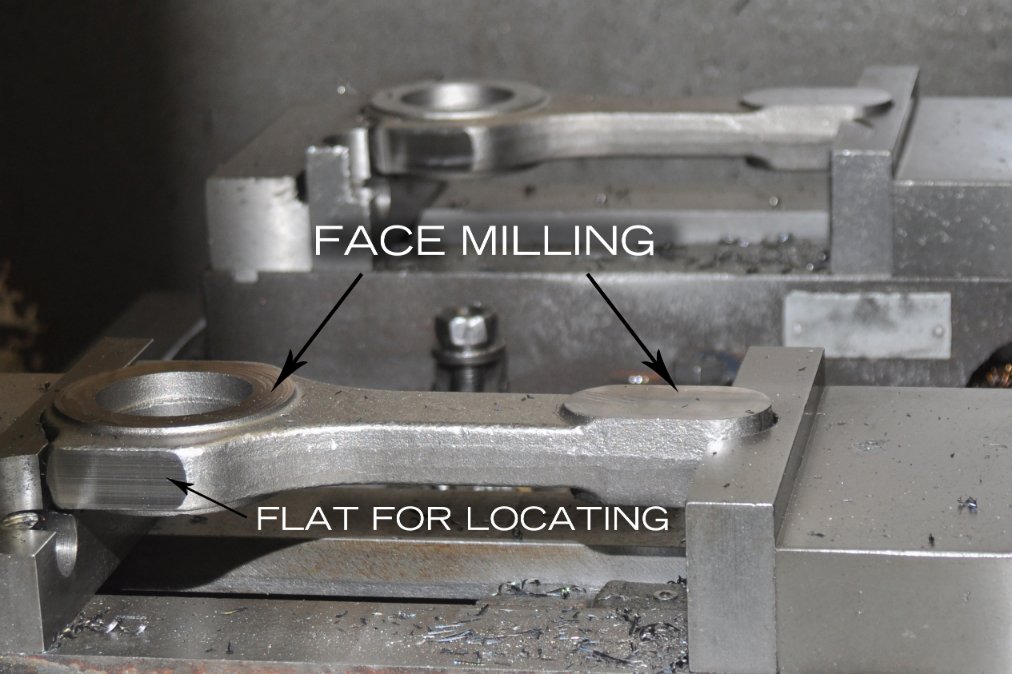

3. CNC Machining Trend #3 – CNC Milled Parts for Precision Bearing Surfaces

A key role of CNC Milled parts in connecting rod production lies in creating precision bearing surfaces. Poor tolerances can lead to catastrophic bearing failure, while precision machining ensures smoother load distribution.

At CNCRUSH, we employ multi-axis CNC milling machines to achieve surface finishes as fine as Ra 0.2 μm, ensuring maximum efficiency and reliability in automotive and automation systems.

4. CNC Machining Trend #4 – CNC Turned Parts for Accurate Pin Ends

CNC Turned parts technology ensures that crankshaft and piston pin ends of connecting rods are machined to perfect concentricity. Even a 0.01 mm deviation can cause excessive wear and imbalance.

By combining CNC milling and turning in our shop floor, CNCRUSH delivers balanced, defect-free connecting rods suitable for both mass production and custom high-performance applications.

5. CNC Machining Trend #5 – The Rise of Hybrid Composite Connecting Rods

Hybrid composites, such as carbon fiber–reinforced metals, are making inroads into next-gen connecting rod designs. CNC Machining of these materials requires specialized tooling and process controls.

While costly, these rods can deliver exceptional fatigue resistance and weight savings—a positive leap forward for industries like automotive, machine building and automation.

6. CNC Machining Trend #6 – Automation in CNC Machining Service for Connecting Rods

Automation is not only the end-use market for connecting rods but also a driving force behind how they are produced. Robotic loading/unloading, automated inspection, and digital twin simulation are transforming CNC machining service efficiency.

At CNCRUSH, we integrate automation into our workflow, ensuring consistent quality while keeping lead times short.

7. CNC Machining Trend #7 – Market Growth of Automotive CNC Machined Connecting Rods

According to industry reports, the global market for automotive connecting rods is expected to grow significantly due to the demand for fuel efficiency and high-performance engines. This growth is directly tied to CNC Machining, as precision components are essential for next-gen engines.

| Market Segment | Growth Driver | CNC Machining Role |

|---|---|---|

| Passenger Vehicles | Lightweight materials | CNC Milled parts ensure efficiency |

| Heavy-Duty Engines | Strength and durability | CNC Turned parts withstand high loads |

| EV/Hybrid Engines | Precision balance | CNC machining ensures smooth performance |

8. CNC Machining Trend #8 – Sustainability in CNC Machining of Connecting Rods

Sustainability is becoming a major factor in manufacturing. CNC manufacturing service providers are focusing on material waste reduction, coolant recycling, and energy-efficient milling techniques.

CNCRUSH actively applies sustainable practices by optimizing tool paths, minimizing waste, and reusing materials wherever possible—an approach that positively impacts both cost and the environment.

9. CNC Machining Trend #9 – Performance Tuning Through CNC Precision

Custom connecting rods for racing engines often require precise tuning of length, mass, and balance. CNC manufacturing enables manufacturers to produce rods that are perfectly suited to specific performance goals.

Negative challenge: Performance tuning requires additional time and expertise, making it unsuitable for mass production. Positive outcome: Unmatched efficiency in competitive automotive environments.

10. CNC Machining Trend #10 – Future of Digital-Integrated CNC Machining Service

The future of CNC manufacturing lies in digital integration—combining CAD/CAM software, real-time monitoring, and predictive analytics to achieve zero-defect manufacturing.

CNCRUSH invests in advanced digital systems, ensuring that our CNC Milled parts and CNC Turned parts consistently meet customer requirements for industries ranging from automotive to automation.

FAQ – CNC Machining and Connecting Rods

Q1: Why is CNC Machining important for connecting rods?

Because connecting rods endure extreme loads, CNC manufacturing ensures the highest possible accuracy, reducing risks of failure.

Q2: What materials are most used in CNC manufacturing connecting rods?

Steel, titanium, aluminum alloys, and increasingly, hybrid composites.

Q3: How does CNCRUSH support custom CNC machining service?

With 12+ years of expertise, CNCRUSH delivers custom CNC Milled parts and CNC Turned parts with strict tolerances and global shipping.

Conclusion

The CNC manufacturing of high-strength connecting rod materials is at the center of innovation in automotive, machine building and automation. From lightweight alloys to digital manufacturing, the trends explored here show how precision machining defines the future of performance and efficiency.

At CNCRUSH, we combine 12 years of expertise with cutting-edge CNC manufacturing service, delivering world-class CNC Milled parts and CNC Turned parts for clients worldwide. Whether you’re developing next-gen automotive engines or designing advanced industrial machinery, CNCRUSH is your reliable partner for success.

Whats up! I just wish to give a huge thumbs up for the great info you’ve here on this post. I will likely be coming again to your blog for more soon.