Turn-Milling Techniques for camshafts have revolutionized modern machining by combining the advantages of turning and milling in a single process. This hybrid approach not only improves productivity but also enables higher precision in complex parts like camshafts, which are critical in automotive, machine building, and automation industries. At CNCRUSH, we specialize in delivering high-quality CNC Milled parts and CNC Turned parts as part of our professional cnc machining service in China. With over 12 years of experience, we understand how to leverage turn-milling for better outcomes.

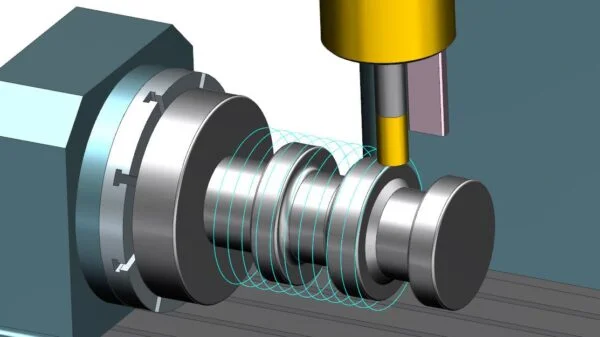

1. Understanding Turn-Milling Techniques for Camshafts

Turn-Milling Techniques combine continuous rotation of the workpiece (turning) with simultaneous milling operations. For camshafts, this method ensures accurate profile generation and reduced cycle times. Unlike traditional processes, turn-milling eliminates the need for multiple setups, resulting in superior consistency and fewer defects. This efficiency is why global manufacturers increasingly rely on turn-milling as part of their cnc machining service.

2. Why Turn-Milling is Critical in Automotive Applications

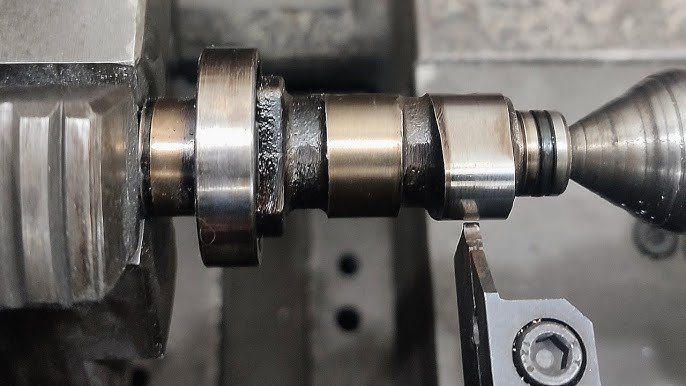

In the automotive industry, camshafts define engine performance. The profiles must be machined with extreme precision to control valve timing and efficiency. A negative sentiment often linked to traditional machining is its inefficiency and high scrap rate. Turn-Milling, however, introduces a positive shift, reducing scrap, improving repeatability, and ensuring smoother cam profiles. This makes it indispensable for high-volume production of CNC Milled parts.

3. Turn-Milling Techniques for High-Strength Materials

Camshafts are commonly made from high-strength steels or alloys. Turn-milling allows effective chip evacuation and heat distribution, lowering the risk of tool wear. Compared to pure turning or milling, the hybrid method manages cutting forces more efficiently, extending tool life and reducing downtime. This balance is crucial for durable CNC Turned parts.

4. Precision and Surface Quality in Turn-Milling

The ability of Turn-Milling Techniques to achieve fine tolerances and superior surface quality is unmatched. A polished finish on cam lobes ensures reduced friction and wear in the engine, enhancing overall performance. This is where CNCRUSH stands out—our inspection systems (CMM, hardness testers, micrometers) guarantee that every CNC Milled part or CNC Turned part we deliver meets strict client requirements.

5. Cost and Time Advantages of Turn-Milling

Turn-Milling reduces cycle times by consolidating operations. It also lowers tooling costs by minimizing tool changes. Compared to traditional machining, which often requires separate milling and turning centers, turn-milling offers a more affordable path. At CNCRUSH, we leverage these efficiencies to provide an affordable cnc machining service that balances price and quality for international clients.

Table 1: Cost and Time Comparison

| Machining Method | Cycle Time | Tooling Costs | Number of Setups | Efficiency |

|---|---|---|---|---|

| Traditional Turning + Milling | High | High | 2-3 | Moderate |

| Turn-Milling Techniques | Reduced | Lower | 1 | High |

6. Tooling Challenges in Turn-Milling Techniques

One negative sentiment often expressed by machinists is the complexity of tooling for turn-milling. Tools must be optimized for both rotational and milling loads. Incorrect selection may result in uneven wear or poor finishes. However, modern CAM software and advanced tooling solutions mitigate these risks, making the process smoother and more predictable.

7. The Role of CAM Software in Turn-Milling

Turn-Milling requires advanced CAM software to synchronize toolpaths and workpiece rotation. CAM packages now provide simulation tools to validate tool engagement and optimize cutting parameters. This ensures reduced errors and higher reliability when producing complex camshaft geometries. For clients seeking consistent CNC Turned parts, CAM-driven processes deliver measurable improvements.

8. Applications Beyond Automotive: Machine Building and Automation

While camshafts dominate discussions, Turn-Milling Techniques are also essential in machine building and automation industries. Components like drive shafts, sprockets, and custom cams benefit from hybrid machining. This versatility underscores the value of turn-milling in modern cnc machining service, extending far beyond automotive applications.

Table 2: Applications of Turn-Milling Across Industries

| Industry | Example Components | Benefits of Turn-Milling |

| Automotive | Camshafts, drive wheels | Precision, efficiency |

| Machine Building | Gear shafts, rollers | Strength, consistency |

| Automation | Sprockets, custom cams | Flexibility, reduced lead time |

9. CNCRUSH: Your Partner for CNC Milled and Turned Parts

At CNCRUSH, we take pride in 12 years of delivering reliable cnc machining services globally. With 7 lathes, 15 three-axis machines, and multiple 4- and 5-axis systems, we are equipped to produce both CNC Milled parts and CNC Turned parts with unmatched quality. Clients in automotive, aerospace, and automation trust us for precision and cost efficiency.

10. The Future of Turn-Milling Techniques for Camshafts

The future of Turn-Milling Techniques lies in further automation, AI-driven toolpath optimization, and advanced materials. As industries demand lighter, stronger, and more complex components, turn-milling will remain at the forefront. For companies seeking a positive competitive edge, partnering with experts like CNCRUSH ensures access to high-quality cnc machining service tailored to global standards.

FAQ: Turn-Milling Techniques for Camshafts

Q1: What is the main advantage of Turn-Milling over traditional methods?

Turn-Milling combines turning and milling in one setup, reducing cycle times, tool changes, and improving precision.

Q2: Why is Turn-Milling important for camshafts?

Camshafts require highly accurate lobes for engine performance. Turn-Milling provides smoother finishes and more consistent geometries.

Q3: Can Turn-Milling handle high-strength materials?

Yes, the process manages cutting forces effectively, extending tool life when machining steels and alloys.

Q4: How does CNCRUSH ensure quality in CNC Milled and Turned parts?

We use advanced inspection equipment such as CMM, hardness testers, and micrometers to ensure every part meets strict specifications.

Q5: What industries benefit most from Turn-Milling Techniques?

Automotive, machine building, and automation industries see the highest value due to precision and efficiency.

Final Thoughts

Turn-Milling Techniques for camshafts represent a powerful leap forward in precision engineering. By integrating turning and milling, manufacturers achieve shorter lead times, lower costs, and superior quality. CNCRUSH is proud to support global clients with high-precision cnc machining service, offering dependable CNC Milled parts and CNC Turned parts for diverse applications.