CNC Turning is one of the most pivotal machining processes in modern manufacturing. This article aims to offer an in-depth exploration of CNC turning, with a focus on its mechanics, applications, advantages, and critical differences from other machining methods such as CNC milling. Drawing on material from sources across the CNC machining industry and aligning with the service offerings of CNCRUSH, a leading CNC machining service provider based in China with over 12 years of experience, we will demonstrate the essential aspects of lathe machining, with practical insights on how this service can be leveraged for various sectors like automotive, machine building, and automation.

1. What is CNC Turning?

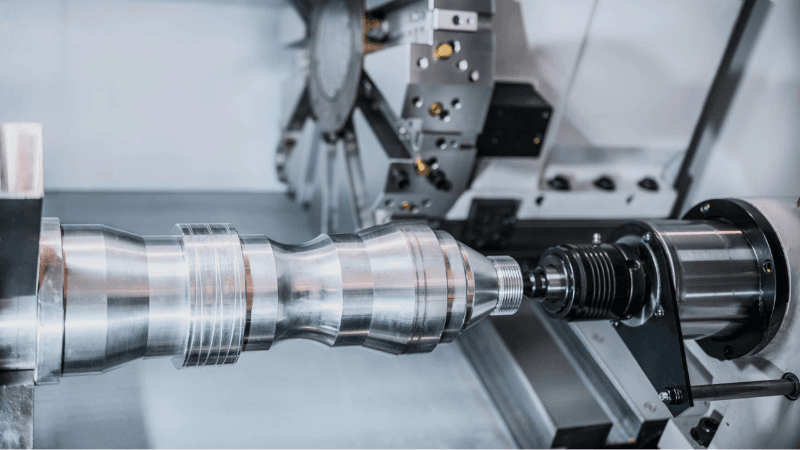

CNC (Computer Numerical Control) turning is a subtractive manufacturing process where material is removed from a rotating workpiece using a stationary cutting tool. Lathe machining is typically employed to create cylindrical parts like shafts, screws, and flanges, and its accuracy and efficiency make it indispensable in industries like automotive and aerospace.

This process uses sophisticated computer programs to guide the cutting tool along predefined paths, ensuring high precision and repeatability. At CNCRUSH, we offer specialized lathe machining services, producing high-quality CNC Turned parts for sectors such as machine building and automotive.

2. How CNC Turning Works

CNC turning starts with the securing of a raw workpiece in a lathe chuck, which rotates around a central axis. A cutting tool, controlled by CNC software, moves linearly or radially to remove material and shape the workpiece. Here’s a simplified breakdown:

- Setup: The raw material is fixed in the chuck, and the cutting tool is selected based on the desired output.

- Programming: CAD/CAM software defines the tool path and sets parameters like cutting speed, depth, and feed rate.

- Execution: The machine removes material while continuously adjusting tool position to create the final product.

- Inspection: Precision checks ensure that the product meets tolerance requirements.

The flexibility of lathe machining allows for various operations like contouring, grooving, threading, and taper turning, each providing different finishes and part designs.

3. Key Components of CNC Turning Machines

To understand lathe machining capabilities, it’s crucial to know its core components:

- Lathe Bed: The base on which all other machine components are mounted, ensuring stability.

- Chuck: Secures the workpiece for rotation.

- Spindle: Holds and spins the workpiece.

- Carriage: Carries the cutting tool and allows it to move along the X and Z axes.

- Cutting Tool: A replaceable tool that removes material as it contacts the rotating workpiece.

- Turret: Holds multiple tools to automate tool changes.

At CNCRUSH, we employ cutting-edge CNC turning machines that are capable of handling intricate designs while maintaining tight tolerances, ensuring precision across various industries.

4. Applications of CNC Turning

CNC turning is versatile and finds applications in a variety of industries:

- Automotive: Manufacturing components like engine shafts, axles, and bushings.

- Machine Building: Creation of precise mechanical parts such as gears and couplings.

- Automation: CNC turning produces parts like pistons, housings, and flanges essential for automation systems.

Given the high precision offered by lathe machining, it is particularly well-suited for the production of parts that require tight dimensional accuracy, such as CNC Turned parts for critical automotive and industrial applications.

5. CNC Turning vs CNC Milling: Key Differences

While both CNC turning and milling are essential machining processes, they differ in terms of methodology and applications. Here’s a comparative table:

| Parameter | CNC Turning | CNC Milling |

|---|---|---|

| Primary Motion | Rotation of the workpiece | Rotation of the cutting tool |

| Shape Produced | Cylindrical parts | Complex shapes (e.g., 3D surfaces) |

| Material Removal | Material removed via a stationary tool | Material removed via moving tool |

| Best For | Shafts, rods, bushings | Gears, brackets, intricate molds |

At CNCRUSH, we offer both CNC Milled parts and lathe machining parts, ensuring that our customers can get the right process for their product needs, whether it’s a high-precision automotive shaft or a complex mechanical component.

6. Advantages of CNC Turning

CNC turning offers several advantages over manual and other forms of machining, making it a preferred process for high-precision components:

- Accuracy: Lathe machining allows for extremely tight tolerances, which are crucial in fields such as automotive and aerospace.

- Consistency: Since the process is computer-controlled, parts are produced with consistent accuracy, even in large volumes.

- Efficiency: Automated operations reduce manual interventions, speeding up the production process and reducing labor costs.

- Scalability: CNC turning is suitable for both prototyping and high-volume production runs, allowing businesses to scale operations as needed.

7. Types of CNC Turning Machines

There are various types of lathe machining, each suited to different kinds of machining tasks:

- Horizontal Lathes: Most common type, ideal for general turning applications.

- Vertical Lathes: Used for larger, heavier workpieces, particularly in industries like aerospace.

- Swiss-Type Lathes: Specialized for small, complex parts requiring high precision.

- Multi-Spindle Lathes: Used for high-volume production where multiple operations are performed simultaneously.

8. Precision in CNC Turning: Industries and Use Cases

CNC turning plays a vital role in multiple sectors due to its versatility and precision:

- Automotive: Production of drive shafts, steering components, and brake cylinders.

- Aerospace: Creation of landing gear components and engine parts requiring stringent tolerances.

- Medical Devices: Precision surgical instruments and implants, benefiting from CNC turning’s ability to handle complex geometries.

9. How to Choose the Right CNC Machining Service Provider

When selecting a CNC machining service provider, consider these factors:

- Experience: CNCRUSH has over 12 years of experience, delivering reliable and precise CNC machining services globally.

- Capability: Ensure the provider can handle both CNC Milled parts and CNC Turned parts, depending on the needs of your project.

- Quality Control: Look for providers with rigorous quality control processes to ensure every part meets exact specifications.

- Lead Time: CNCRUSH offers fast turnarounds, enabling you to meet production deadlines efficiently.

10. CNC Turning and Milling for Automotive, Machine Building, and Automation

At CNCRUSH, we specialize in providing CNC machining services for sectors like automotive, machine building, and automation. Our expertise ensures that every part is manufactured to the highest standards, whether it’s a CNC Turned part for a car engine or a CNC Milled part for an industrial machine.

Conclusion

Lathe machining remains a fundamental process in modern manufacturing. Whether you’re producing precision parts for the automotive industry or complex components for machine building and automation, lathe machining offers unparalleled precision, repeatability, and scalability. By partnering with a trusted CNC machining provider like CNCRUSH, with over a decade of experience, businesses can ensure that their parts meet the stringent demands of today’s industries. Explore our CNC machining services for a reliable and high-quality manufacturing solution tailored to your needs.

FAQ Section

1. What materials are best suited for lathe machining?

CNC turning works well with metals like aluminum, brass, steel, and titanium, as well as plastics and composites.

2. Can CNC turning handle complex geometries?

Yes, while CNC turning is ideal for cylindrical parts, advanced machines can handle intricate features like grooves, threads, and tapers.

3. What industries benefit most from lathe machining?

Industries like automotive, aerospace, medical devices, and industrial manufacturing rely heavily on lathe machining for high-precision components.

4. How does lathe machining compare with CNC milling?

While CNC turning is optimal for cylindrical parts, CNC milling is used for more complex geometries.