The focus keyword, “CNC Milling,” introduces the unmatched precision, flexibility, and efficiency that Computer Numerical Control (CNC) milling technology brings to metal fabrication. CNC milling has become pivotal for industries requiring high-precision components, like automotive, aerospace, and electronics. This process offers not only accuracy but also repeatability, cost-efficiency, and speed, making it indispensable for manufacturers who aim for the highest quality in CNC-milled parts. Here, we discuss ten essential benefits of CNC milling, emphasizing the unmatched capabilities available through specialized CNC machining services like those provided by CNCRUSH, a China-based CNC machining factory with over 12 years of experience in CNC milled parts and CNC turned parts.

Table of Contents

- What is CNC Milling?

- High-Precision and Consistency in Manufacturing

- Enhanced Efficiency and Cost Reduction

- Versatile Material Compatibility

- Advanced 5-Axis Capabilities

- Precision for Complex Geometries

- Reduced Material Waste

- Shorter Production Lead Times

- Customization and Prototyping Advantages

- Improved Safety and Automation in the Workplace

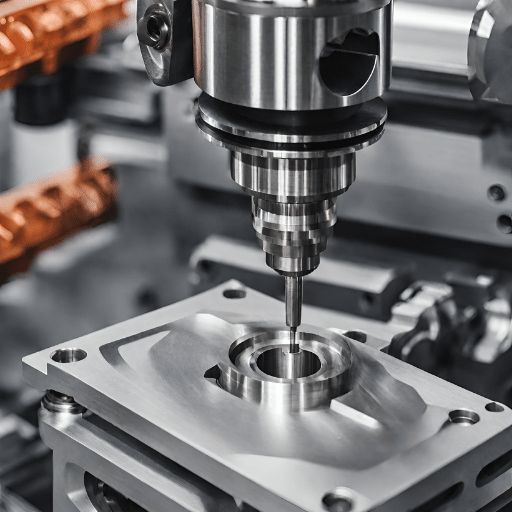

1. What is CNC Milling?

At its core, CNC milling involves the use of computer-controlled, rotating tools to remove material from a workpiece, creating shapes and features with exceptional precision. With advancements in technology, CNC milling machines can now execute intricate designs in metals, plastics, and even composites, offering a range of applications across sectors like automotive, machine building, and automation. Compared to manual processes, CNC milling offers improved accuracy and repeatability, critical for precision metal parts manufacturing.

2. High-Precision and Consistency in Manufacturing

For manufacturers like CNCRUSH specializing in high-precision CNC machining services, the consistency provided by CNC milling technology is essential. CNC milling machines can achieve tolerances within microns, an accuracy level that would be difficult, if not impossible, to maintain with manual methods. This precision enables industries like automotive and aerospace to meet strict requirements, ensuring each part fits perfectly into complex assemblies without requiring additional adjustments.

3. Enhanced Efficiency and Cost Reduction

CNC milling also reduces production times, cutting costs significantly. By automating tasks, CNC milled allows for uninterrupted production with minimal supervision. CNCRUSH, for instance, leverages this technology to deliver parts faster, giving businesses an edge in meeting tight deadlines. Moreover, the automation reduces the likelihood of human error, further decreasing costs associated with rework or waste.

4. Versatile Material Compatibility

CNC milled is compatible with various materials, including aluminum, steel, brass, and plastics. This versatility is advantageous for clients requiring custom CNC solutions across different material specifications. For example, CNCRUSH provides specialized CNC machining services for aluminum and steel parts, ensuring their components meet exact industry requirements.

| Material Type | Key Properties | Common Applications in CNC Milling |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Automotive, aerospace, electronics |

| Steel | High strength, versatile | Construction, heavy machinery |

| Brass | High corrosion resistance, good electrical conductivity | Electronics, plumbing |

| Plastic | Lightweight, flexible | Prototyping, consumer goods |

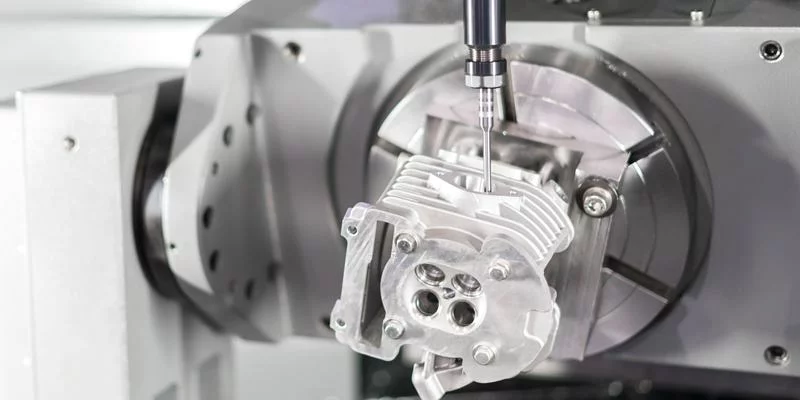

5. Advanced 5-Axis Capabilities

5-axis CNC milling technology introduces another dimension of versatility by enabling the cutting tool to move across five axes. This feature is ideal for creating complex geometries without multiple setups, reducing the overall lead time. For a precision-driven industry such as medical devices, 5-axis milling is invaluable. CNCRUSH’s CNC milling services offer advanced capabilities, making it possible to manufacture sophisticated parts for clients needing top-tier quality.

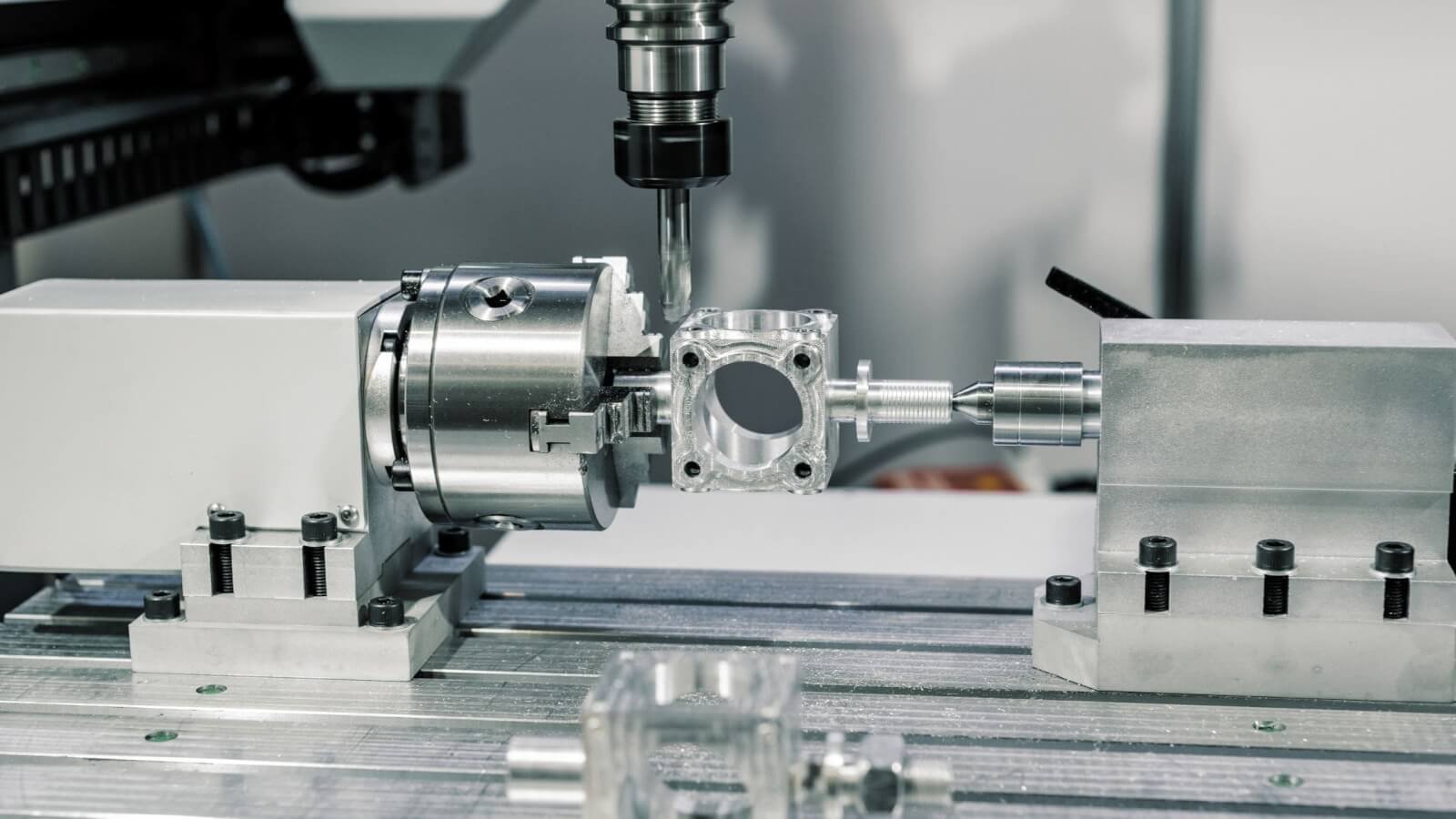

6. Precision for Complex Geometries

CNC milling’s capability to produce complex, multi-faceted designs opens new possibilities for sectors like machine building and automation. With computer-aided designs, CNC milled can achieve shapes and contours that would be challenging with traditional methods. Companies like CNCRUSH can seamlessly handle complex projects, supporting clients from prototyping to final production.

7. Reduced Material Waste

The precise control over cutting tools in CNC milled significantly reduces material waste. CNC programs optimize the use of raw materials, reducing scrap and achieving better yields from the same material batch. This waste reduction not only brings down material costs but also aligns with sustainable manufacturing practices. By leveraging CNC technology, CNCRUSH ensures that clients receive affordable CNC machining without sacrificing quality.

8. Shorter Production Lead Times

CNC milling’s efficiency dramatically shortens production times. CNCRUSH, for example, offers rapid turnaround without compromising precision. The streamlined CNC milling process means projects are completed faster, which is a substantial advantage in time-sensitive industries like automotive manufacturing and aerospace.

9. Customization and Prototyping Advantages

CNC milled is ideal for producing custom parts and prototyping. Customization allows businesses to create parts tailored to specific applications. Moreover, prototyping with CNC milling facilitates design testing before mass production. CNCRUSH’s custom CNC solutions support clients from prototyping to production, ensuring that parts meet functional and aesthetic requirements.

10. Improved Safety and Automation in the Workplace

Automation in CNC milled not only improves efficiency but also enhances workplace safety. With automated processes, there’s less manual handling of sharp or heavy tools, reducing injury risk. Additionally, CNC milling can run unattended, enabling a safer, low-supervision environment. As a result, CNCRUSH can deliver high-quality CNC machining services while maintaining safety standards, benefitting both workers and clients alike.

Frequently Asked Questions (FAQ)

1. What industries benefit most from CNC milling?

- CNC milling is widely used in industries like automotive, aerospace, electronics, medical, and machinery. Each of these sectors requires precision and repeatability, making CNC milling ideal for high-quality metal parts manufacturing.

2. How does CNC milling compare to CNC turning?

- While CNC milling involves rotating the cutting tool to remove material from a stationary workpiece, CNC turning rotates the workpiece itself. Both techniques are valuable, but milling is better suited for creating complex shapes, whereas turning is ideal for cylindrical parts.

3. Why choose CNCRUSH for CNC machining services?

- With over 12 years of experience, CNCRUSH offers specialized CNC machining in China, providing high-precision CNC milled and turned parts. The factory’s expertise and advanced capabilities ensure top-tier service for global clients.

Conclusion

CNC milling offers numerous advantages, from precision and efficiency to material versatility. In sectors that demand high-quality CNC-milled parts, CNCRUSH stands out as a trusted provider with over a decade of experience. For businesses in automotive, machine building, automation, or any industry requiring superior machining quality, CNCRUSH’s expertise in CNC machining services provides a reliable partnership for both standard and custom CNC solutions.