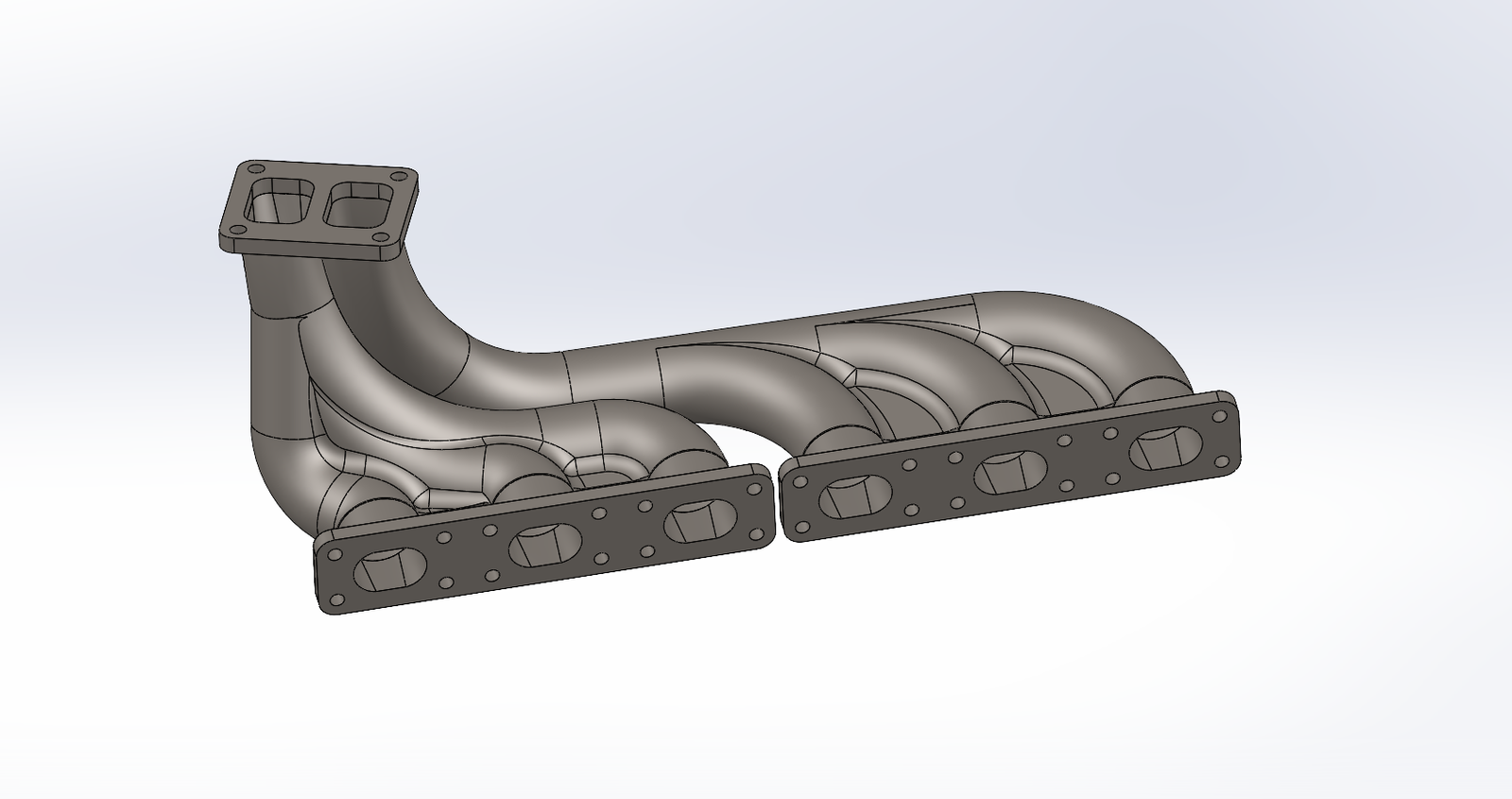

CNC Machining is the foundation of modern exhaust manifold manufacturing, especially when thermal stress, fatigue failure, and long-term durability become critical challenges in high-temperature automotive environments.

Introduction: Why Thermal Stress Makes Exhaust Manifolds a High-Risk Component

Exhaust manifolds operate in one of the harshest environments inside an engine. Continuous exposure to extreme temperatures, thermal cycling, vibration, and corrosive exhaust gases creates a high failure risk if design, material selection, or manufacturing precision is inadequate.

Across industry research and engineering studies, the same conclusions repeatedly appear: thermal stress concentration, material mismatch, and machining inaccuracies are the main reasons exhaust manifolds crack, warp, or prematurely fail.

This article transforms those insights into practical CNC machining strategies, combining academic research depth with real-world manufacturing experience. Drawing from high-temperature machining challenges and thermal fatigue studies, we provide 10 deeply analyzed approaches to control thermal stress using advanced CNC machining service techniques—especially for automotive, machine building and automotion industries.

1: CNC Machining and Thermal Stress Fundamentals in Exhaust Manifolds

Thermal stress occurs when temperature gradients cause uneven expansion and contraction inside the exhaust manifold. Poor thermal management leads to negative outcomes such as cracking near flanges or deformation around ports.

From a CNC Machining perspective, precision matters more than brute material strength. Even the best alloys fail if machining tolerances allow stress concentration points.

Key contributors to thermal stress include:

-

Uneven wall thickness

-

Sharp internal corners

-

Inconsistent surface finish

-

Improper machining sequences

A professional cnc machining service must understand not only geometry, but also thermal behavior during real engine cycles.

2: CNC Machining Service Material Selection for High-Temperature Stability

Material choice directly influences thermal fatigue resistance. Stainless steel, ductile iron, and aluminum alloys behave very differently under heat.

| Material | Thermal Conductivity | Fatigue Resistance | CNC Machining Difficulty |

|---|---|---|---|

| Aluminum Alloy | High | Low–Medium | Easy |

| Stainless Steel | Medium | High | Difficult |

| Ductile Iron | Low | Very High | Moderate |

A skilled CNC Machining service adjusts tool paths, feeds, and cutting strategies based on material-specific thermal expansion behavior.

At CNCRUSH, we machine aluminum and steel exhaust components with 12 years of experience, ensuring materials are matched precisely to application demands.

3: CNC Machining of Wall Thickness for Thermal Stress Balance

Uneven wall thickness is a silent failure trigger. Thicker sections cool slower, while thinner areas contract faster—creating destructive internal stress.

Using CNC Milled parts, manufacturers can:

-

Maintain consistent wall transitions

-

Optimize thickness gradients

-

Reduce thermal hotspots

Advanced CNC Machining allows multi-axis milling to create smooth internal geometries that casting alone cannot achieve.

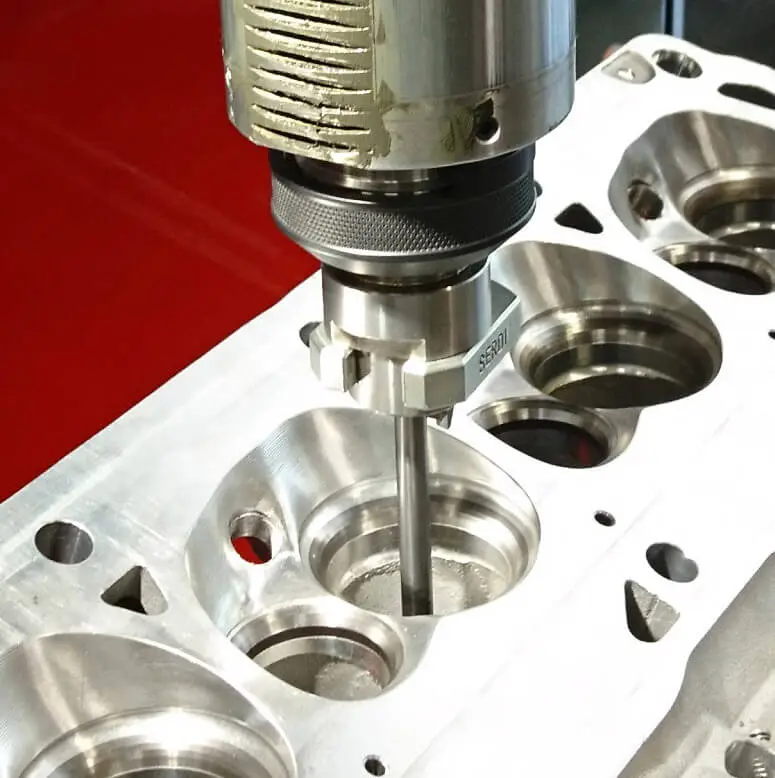

4: CNC Turned Parts and Flange Precision Under Thermal Load

Flanges are critical sealing interfaces and often the first failure zone.

Poorly machined flanges cause:

-

Exhaust leaks

-

Warping under heat

-

Bolt loosening

Precision CNC Turned parts ensure:

-

Perfect flatness

-

Uniform bolt stress distribution

-

Improved gasket lifespan

A professional cnc machining service understands that micron-level errors multiply under thermal expansion.

5: CNC Machining Surface Finish and Its Impact on Thermal Fatigue

Surface roughness increases crack initiation probability. Micro-notches act as stress amplifiers under thermal cycling.

| Surface Finish (Ra) | Crack Risk | Thermal Fatigue Resistance |

|---|---|---|

| >3.2 µm | High | Poor |

| 1.6–3.2 µm | Medium | Acceptable |

| <1.6 µm | Low | Excellent |

Using optimized CNC Machining parameters for CNC Milled parts dramatically improves component lifespan.

6: CNC Machining Service Toolpath Strategy for Heat Control

Toolpath design directly affects residual stress. Aggressive cutting generates localized heat that becomes locked into the part.

Smart CNC Machining service strategies include:

-

Symmetrical machining sequences

-

Adaptive clearing

-

Heat-balanced roughing

These methods reduce internal stress accumulation—critical for exhaust components exposed to constant heat cycling.

7: CNC Machining and Thermal Expansion Compensation Techniques

Thermal expansion compensation is often overlooked but emotionally frustrating when ignored—leading to rejected parts and customer complaints.

Professional CNC Machining compensates for:

-

Material expansion during cutting

-

Cooling shrinkage

-

Post-machining heat exposure

At CNCRUSH, real-time machining experience allows predictive compensation that prevents dimensional drift in automotive applications.

8: CNC Milled Parts vs Cast Geometry in Exhaust Manifolds

Casting offers complexity, but CNC Milled parts deliver precision and reliability.

| Aspect | Casting | CNC Machining |

|---|---|---|

| Dimensional Accuracy | Low | Very High |

| Thermal Stress Control | Poor | Excellent |

| Repeatability | Medium | Outstanding |

Hybrid manufacturing—casting plus CNC Machining service—provides the best balance for performance exhaust systems.

9: CNC Turned Parts in Sensor Ports and Mounting Interfaces

Sensor ports experience constant thermal shock. Poorly machined threads lead to sensor failure or leakage.

Precision CNC Turned parts ensure:

-

Thread integrity under heat

-

Repeatable torque values

-

Long-term sensor reliability

This level of machining is essential in automotion and advanced engine systems.

10: CNC Machining Service Quality Control for Thermal Reliability

Thermal stress failures are expensive and damaging to brand reputation. Strong quality control is non-negotiable.

Effective CNC Machining service quality checks include:

-

CMM inspection

-

Surface roughness testing

-

Thermal simulation validation

At CNCRUSH, every CNC Milled part and CNC Turned part undergoes strict inspection to ensure performance consistency.

Why Choose CNCRUSH for CNC manufacturing of Exhaust Manifolds

CNCRUSH is a China-based professional CNC manufacturing service provider with over 12 years of manufacturing experience, trusted by global clients.

We specialize in:

-

CNC Milled parts

-

CNC Turned parts

-

Automotive, machine building and automotion applications

-

Aluminum and steel precision components

If you are seeking reliable CNC Machining with real thermal engineering understanding, CNCRUSH delivers confidence—not excuses.

Frequently Asked Questions (FAQ)

Q1: Why is CNC Machining better than casting alone for exhaust manifolds?

CNC Machining ensures tighter tolerances, smoother surfaces, and better thermal stress control than casting alone.

Q2: Can aluminum exhaust manifolds survive high temperatures?

Yes, when properly designed and machined, aluminum manifolds with CNC manufacturing can perform reliably in controlled thermal environments.

Q3: How do CNC Milled parts reduce thermal fatigue?

They eliminate sharp corners, maintain uniform wall thickness, and reduce surface defects that initiate cracks.

Q4: Why are CNC Turned parts critical for sensor ports?

They ensure precise threads and sealing surfaces that remain stable under thermal cycling.

Q5: What industries benefit most from this CNC manufacturing approach?

Automotive, machine building and automotion industries benefit the most from precision thermal stress control.

Final Thoughts: CNC Manufacturing Is the Difference Between Failure and Confidence

Thermal stress is unforgiving. There is no margin for careless machining in exhaust manifolds. Precision, experience, and deep thermal understanding separate reliable components from costly failures.

If you are looking for a professional CNC manufacturing service that understands both engineering theory and real-world manufacturing pressure, CNCRUSH is ready to support your next project.